Water self-dispersing grease microcapsule and preparation method thereof

A microcapsule, self-dispersing technology, applied in food science and other directions, can solve problems such as inability to uniformly disperse emulsion, and achieve the effects of low cost, simple process and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The porous maltodextrin encapsulates vitamin E, vitamin A, and astaxanthin, and the percentages of each raw material are shown in Table 1.

[0047] Table 1

[0048] raw material percentage Remark Porous Maltodextrin 50 Adsorption raw material sunflower oil 31 grease Vitamin E 1 Active Vitamin A 1 Active Astaxanthin 0.5 Active glycerin 15 Emulsifier solubilizer Sodium Subtilisin 1.5 Emulsifier total 100

[0049] Its preparation steps are as follows:

[0050] 1) Heat and dissolve sodium subtilisin and 10 parts of glycerin in a water bath at 50°C, and then mix with the remaining glycerin evenly;

[0051] 2) dissolve vitamin E and A, astaxanthin into sunflower oil;

[0052] 3) mixing and homogenizing 1) and 2) to obtain an oil-in-glycerin oil phase mixture;

[0053] 4) Stir 3) into the porous maltodextrin.

[0054] The oil-in-glycerin mixture obtained in step 3) has a certain viscosity at roo...

Embodiment 2

[0058] Table 2 shows the percentage of each raw material for the easily dispersible clay film paste powder coated with oil and vitamin C.

[0059] Table 2

[0060] raw material percentage Remark bentonite 14 adsorbent Kaolin 50 adsorbent Sodium Carboxymethyl Starch 1 thickener, disintegrant Caprylic acid sunflower triglyceride 5 grease Myristate Nutmeg 5 grease shea butter 10 grease Monoglycerides 10 Emulsifier Vitamin C 5 active agent total 100

[0061] Its preparation steps are as follows:

[0062] 1) Heat the monoglyceride and the three oils to 60 degrees to fully melt, and mix them evenly;

[0063] 2) Add vitamin C powder and keep stirring;

[0064] 3) Use the fluidized bed top spray equipment to make the bentonite and kaolin into a flowing boiling state under the blowing of the inlet air, and the inlet air does not need to be heated;

[0065] 4) The melted grease containing vitamin...

Embodiment 3

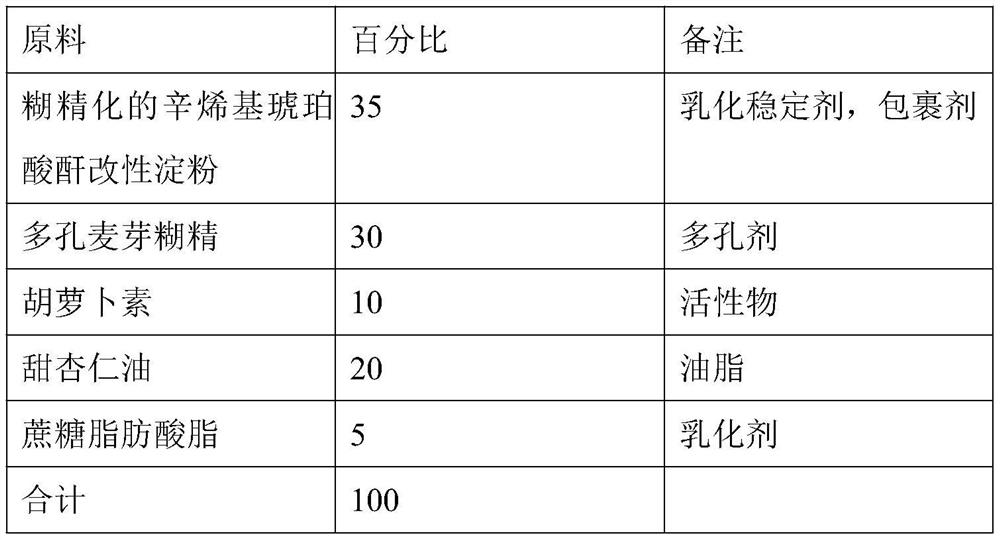

[0069] Carotene particles, the percentages of each raw material are shown in Table 3.

[0070] table 3

[0071]

[0072] Its preparation steps are as follows:

[0073] 1) Heat the sucrose fat and sweet almond oil to 40 degrees and mix and dissolve, and then cool down;

[0074] 2) dissolve and mix carotene into 1);

[0075] 3) spray the mixture obtained in step 2) into the porous maltodextrin, so that the porous maltodextrin can fully absorb the oil;

[0076] 4) The product obtained in step 3) is extruded into granules through an extruder, and then spheronized into spherical granules by a shot blasting machine.

[0077] While spheronizing, the dextrinized octenyl succinic anhydride-modified starch is thrown onto the granules formed by dextrin and oil to obtain a microcapsule encapsulated by the dextrinized octenyl succinic anhydride-modified starch powder shell. The diameter of the microcapsules is between 0.1-2 mm, and ideally, the diameter is between 0.5-1.5 mm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com