Attapulgite-based composite heavy metal adsorbent and preparation method thereof

A technology of attapulgite and heavy metals, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve the problems of high preparation cost of heavy metal ion adsorbents, easy damage to the ecological environment, and ineffective treatment effects , achieve the effect of low preparation cost, increase adsorption effect, and save enterprise operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a composite heavy metal adsorbent based on attapulgite, comprising the following steps: calcining the attapulgite and pulverizing the attapulgite to obtain attapulgite powder; placing the dried leaves in a tube furnace, The nitrogen atmosphere was turned on, and the nitrogen inflow rate was 25 mL / min. The temperature of the carbonization is 300-350°C. After the carbonization is completed, the tube furnace is cooled to room temperature and taken out to obtain the biochar; the biochar is immersed in a 1 mol / L citric acid solution, After ultrasonic treatment, biochar activated by citric acid is obtained; the mass-volume ratio of biochar to citric acid is 1g:60mL (W:V), and the ultrasonic treatment is interval ultrasonic, specifically ultrasonic treatment 3 to 5 times, each time Ultrasonic treatment was performed for 1 to 3 hours, with an interval of 2 to 4 hours after ultrasonic treatment.

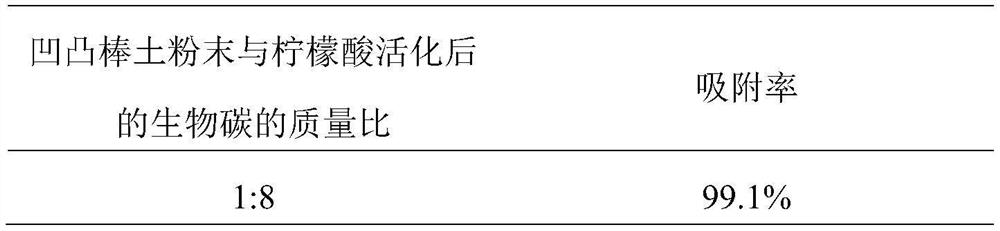

[0031] Mix attapulgite powder and citric acid-activated bi...

Embodiment 2

[0033] Adsorption experiments under different pH conditions:

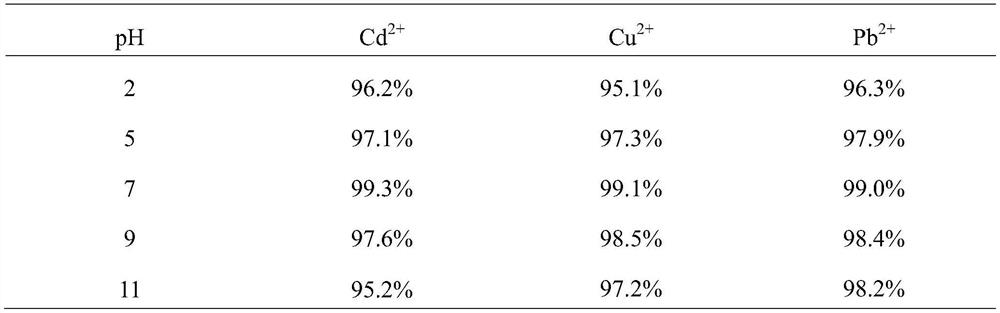

[0034] Prepared separately with different pH and containing 50mg / L Cd 2+ , 50mg / L Cu 2+ , 50mg / L Pb 2+ 100 mL of simulated wastewater was put into each group of simulated wastewater, and 0.1 g of the composite heavy metal adsorbent prepared by the method in Example 1 was put into each group of simulated wastewater. After adsorption for 1-2 min, the Cd in the solution was measured. 2+ The adsorption rate under different pH conditions is shown in the following table:

[0035]

[0036] As can be seen from the above table, under different pH conditions, the adsorbent of the present invention has a strong effect on Cd 2+ , Cu 2+ , Pb 2+The adsorption rate of the samples reached more than 95%, and good adsorption effects were achieved under different pH conditions. The adsorbent particles of the invention show high stability to strong acids and alkalis, and have strong adsorption capacity for cadmium ions, coppe...

Embodiment 3

[0038] Adsorption experiments under different temperature hydrothermal reactions:

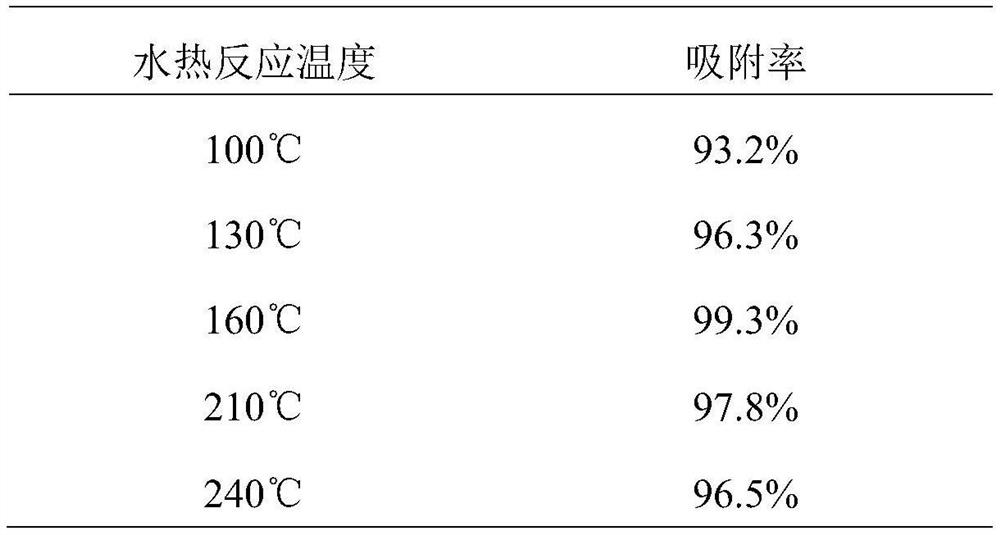

[0039] The composite heavy metal adsorbent was prepared by hydrothermal reaction at different temperatures, and other conditions were the same as in Example 1, and 0.1 g of the obtained adsorbent was put into 10 mg / L Cd 2+ 100mL of simulated wastewater (pH is 7), after adsorption for 1-2min, the Cd in the solution was determined 2+ The results are shown in the following table:

[0040]

[0041] It can be seen from the above table that the best adsorption effect was achieved when the hydrothermal reaction temperature was 160 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com