Carbon-coated lithium ferric manganese phosphate positive electrode material and preparation method thereof

A technology of lithium iron manganese phosphate and positive electrode materials, applied in the direction of carbon preparation/purification, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of poor performance of lithium-ion batteries, limited electrochemical performance, and reduced electrical conductivity, etc., to achieve Fast de-intercalation speed, reduced diffusion distance, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of a carbon-coated lithium iron manganese phosphate cathode material, comprising the following steps:

[0027] (1) mixing lithium source, iron source, manganese source, titanium source, phosphorus source and solvent to obtain mixed system A;

[0028] (2) mixing carbon source and solvent to obtain mixed system B;

[0029] (3) Electrospinning the mixed system A and the mixed system B to obtain a fiber body;

[0030] (4) calcining the fiber body to obtain the carbon-coated lithium iron manganese phosphate cathode material.

[0031] In the present invention, the lithium source in the step (1) is preferably lithium carbonate, lithium acetate or lithium hydroxide; the iron source is preferably ferrous oxalate, ferrous sulfate heptahydrate or ferrous phosphate octahydrate; the The manganese source is preferably manganese acetate, manganese carbonate or manganese dioxide; the titanium source is preferably titanium dioxide or tetrabu...

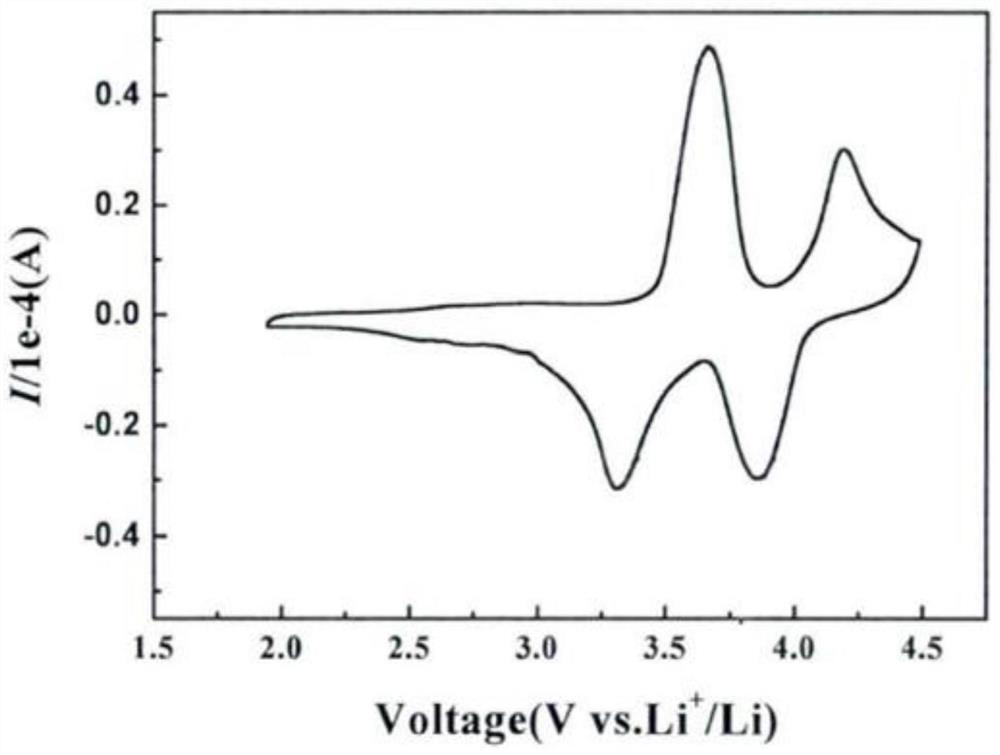

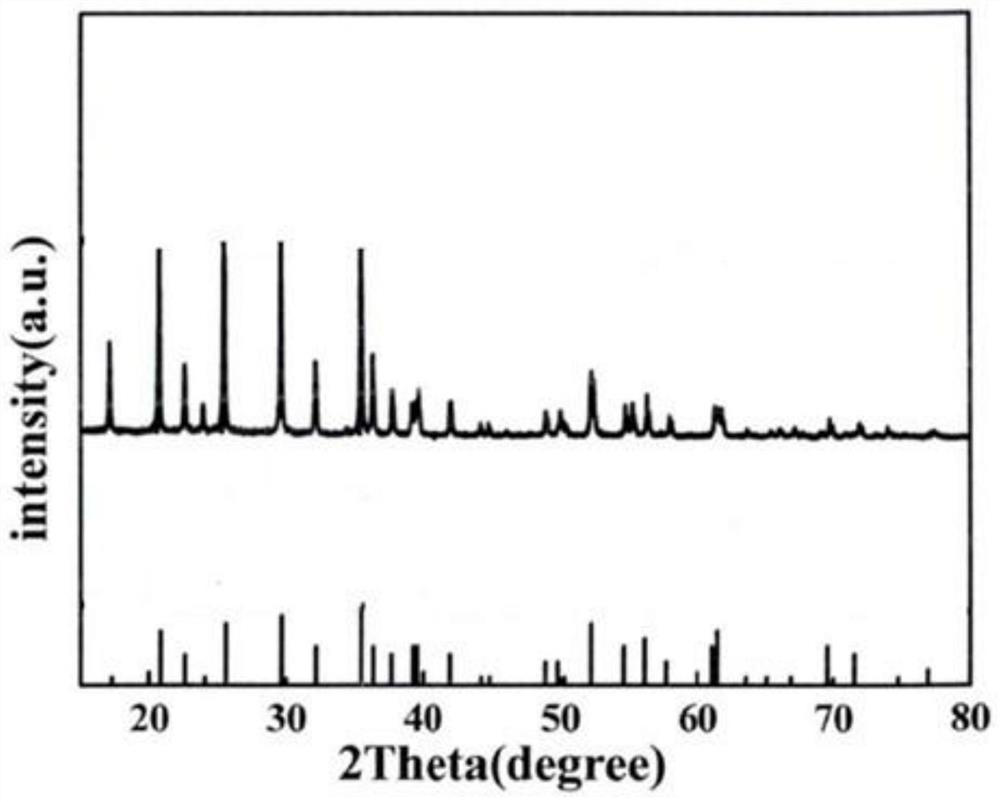

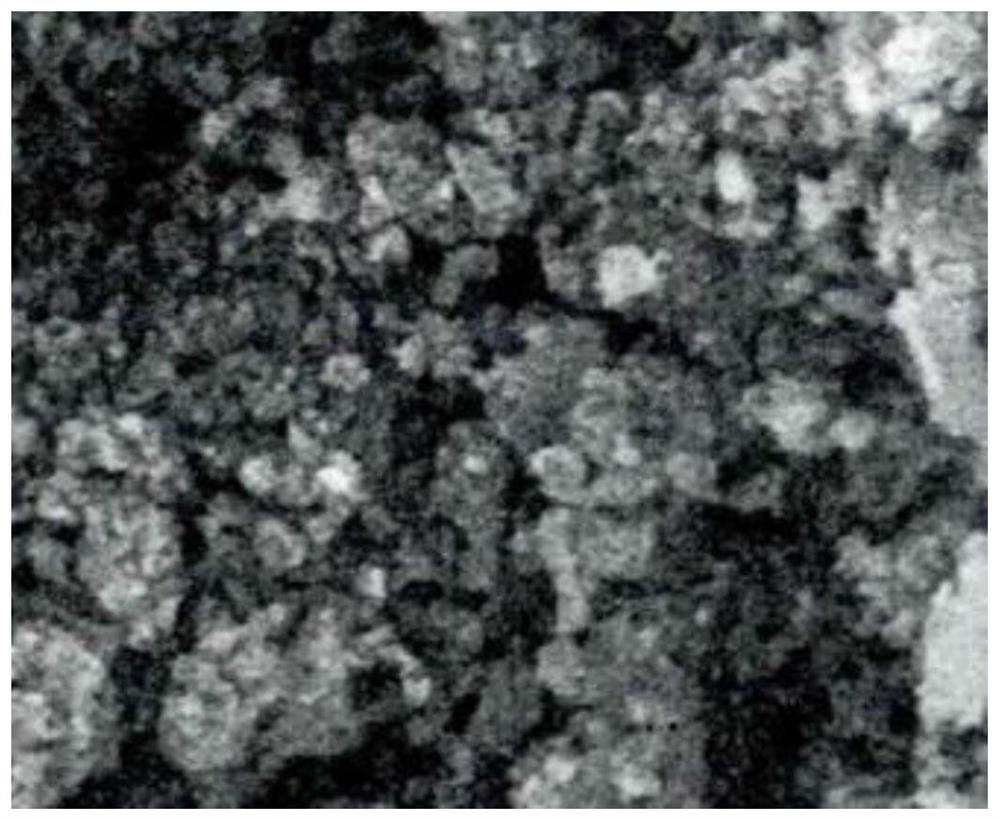

Embodiment 1

[0045] Take 0.1mol of lithium carbonate, 0.035mol of ferrous oxalate, 0.035mol of manganese acetate, 0.03mol of titanium dioxide, 0.1mol of ammonium dihydrogen phosphate and 0.15L of N,N-dimethylformamide, under the condition of 70KHz The mixed system A was obtained by sonicating for 1.5 h.

[0046] Take 4.5 g of glucose and 20 mL of solvent, the volume ratio of water and N,N-dimethylformamide in the solvent is 1:1, and stir at 150 rpm for 10 min to obtain a mixed system B.

[0047] The hybrid system A and the hybrid system B were electrospinned by cross-pair spinning, the voltage was 45kV, the bolus rate was 1mL / h, the inner diameter of the needle was 0.5mm, the distance between the needle and the receiving drum was 20cm, and the temperature was 35°C to obtain a fibrous body.

[0048] The fibers were calcined at 200 °C for 3 h, then increased to 500 °C at a heating rate of 2 °C / min, calcined at 500 °C for 4 h, then increased to 850 °C at a heating rate of 2 °C / min, and calci...

Embodiment 2

[0054] Take 0.5mol lithium acetate, 0.15mol ferrous sulfate heptahydrate, 0.2mol manganese carbonate, 0.1mol tetrabutyl titanate, 0.6mol diammonium hydrogen phosphate and 0.5L dimethyl sulfoxide, at 80KHz Under the condition of sonication for 1 h, the mixed system A was obtained.

[0055] Take 22.5 g of citric acid and 150 mL of solvent, the volume ratio of water and dimethyl sulfoxide in the solvent is 1:0.5, and stir at 100 rpm for 20 min to obtain a mixed system B.

[0056] The hybrid system A and the hybrid system B were electrospun by means of cross-pair spinning, the voltage was 40kV, the bolus rate was 0.8mL / h, the inner diameter of the needle was 0.6mm, the distance between the needle and the receiving drum was 15cm, and the temperature was 15cm. At 30°C, a fibrous body was obtained.

[0057] The fibers were calcined at 150 °C for 4 h, then raised to 400 °C at a heating rate of 1 °C / min, calcined at 400 °C for 3 h, then raised to 800 °C at a heating rate of 2 °C / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com