PIN diode based on n-type gallium oxide and p-type diamond and preparation method thereof

A technology of PIN diode and gallium oxide, which is applied in the field of PIN diode and its preparation, can solve the problems of obvious thermal effect, large reverse leakage current, low diode reverse bias voltage, etc., and achieve high carrier mobility and wide bandgap width , On-resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

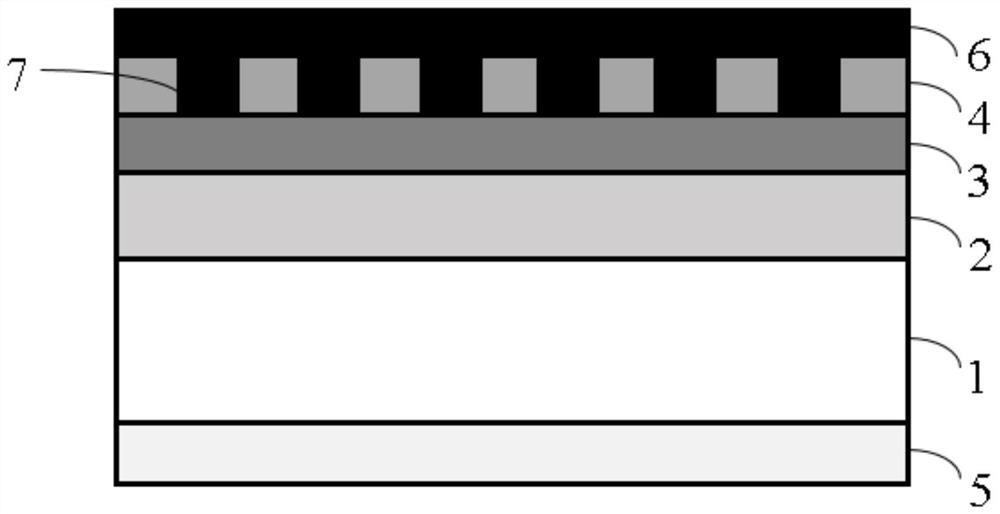

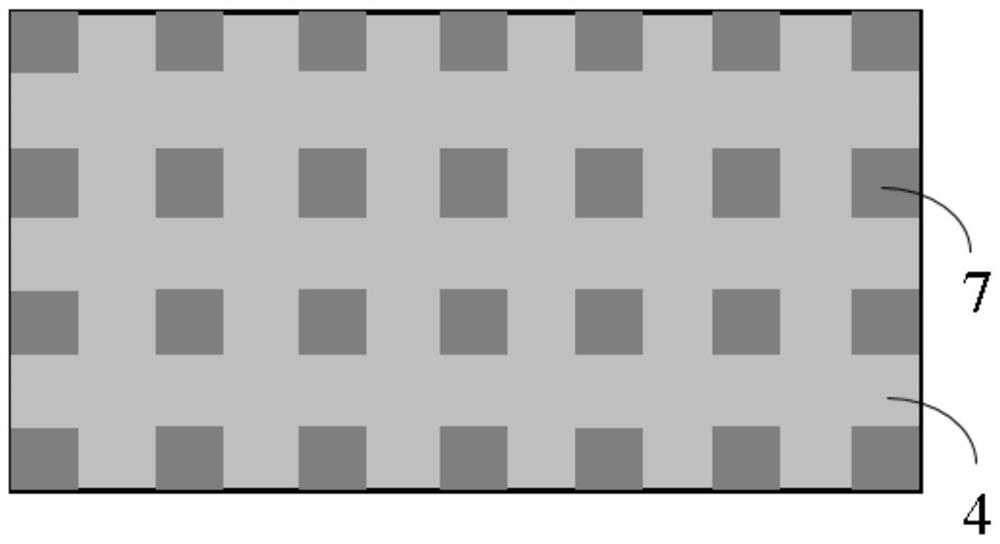

[0040] See figure 1 , figure 1 It is a schematic structural diagram of a PIN diode based on n-type gallium oxide and p-type diamond provided by an embodiment of the present invention. The PIN diode includes n + -Ga 2 O 3 Substrate layer 1, n - -Ga 2 O 3 Layer 2, p + Type diamond layer 3, p ++ type diamond layer 4, cathode layer 5 and anode layer 6, wherein the cathode layer 5, n + -Ga 2 O 3 Substrate layer 1, n - -Ga 2 O 3 layer 2 and p + The diamond layers 3 are arranged in sequence from bottom to top, p ++ The p+-type diamond layer 4 is arranged on the upper surface of the p+-type diamond layer 3 .

[0041] Further, n - -Ga 2 O 3 The doping concentration of layer 2 is less than n + -Ga 2 O 3 Doping concentration of substrate layer 1 . The substrate selected in this embodiment is heavily doped n-type gallium oxide (n + -Ga 2 O 3 ) substrate, n + -Ga 2 O 3 The doping concentration of the substrate layer 1 is 10 18 ~10 20 cm -3 , the thickness is...

Embodiment 2

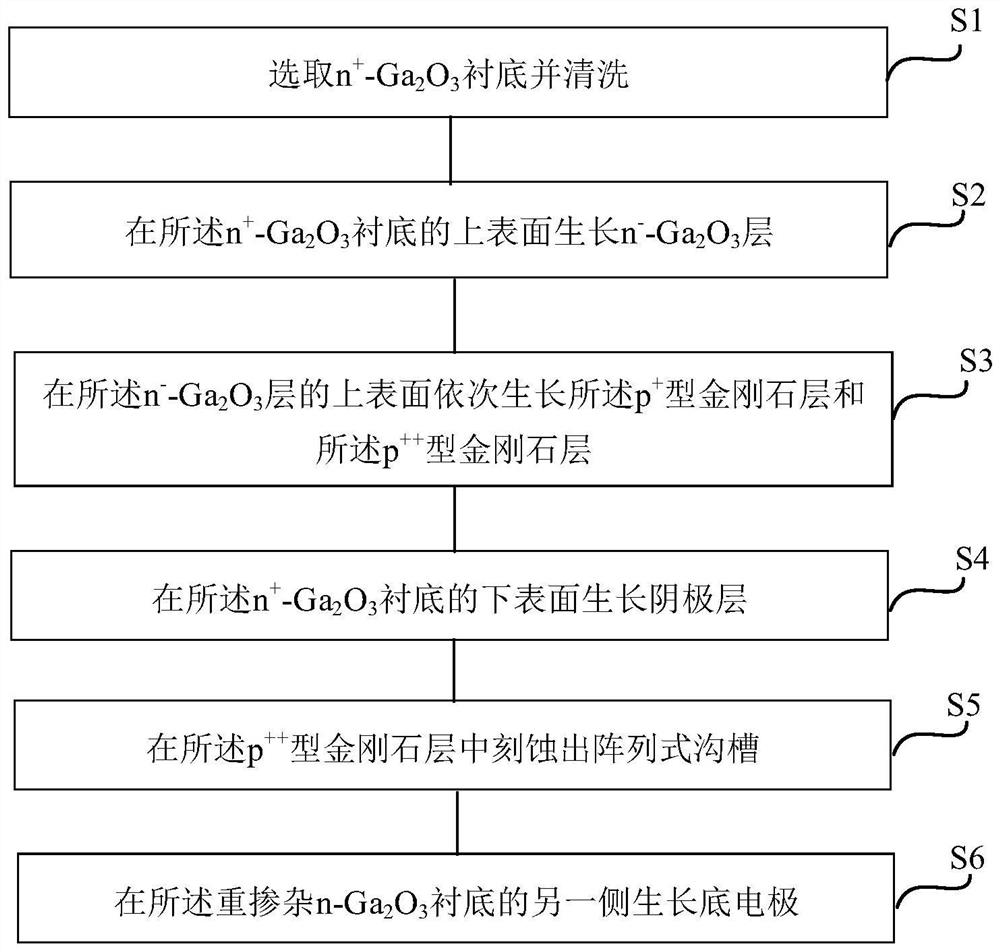

[0048] On the basis of Embodiment 1, this embodiment provides a preparation method of a PIN diode based on n-type gallium oxide and p-type diamond. See image 3 , image 3 It is a flow chart of a preparation method of a PIN diode based on n-type gallium oxide and p-type diamond provided by the embodiment of the present invention, and the preparation method includes:

[0049] S1: choose n + -Ga 2 O 3 Substrate 1 and cleaned.

[0050] Specifically, the doping concentration is selected as 1018 ~10 20 cm -3 , heavily doped n-type gallium oxide (n + -Ga 2 O 3 ) Substrate 1 and standard cleaning.

[0051] S2: at the n + -Ga 2 O 3 The upper surface of substrate 1 grows n - -Ga 2 O 3 layer 2, and the n - -Ga 2 O 3 The doping concentration of the layer is less than the n + -Ga 2 O 3 Doping concentration of the substrate layer.

[0052] Specifically, using a metal organic chemical vapor deposition (MOCVD) process or a hydride vapor phase epitaxy (HVPE) process, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com