Process for preparing nano CaCO3/SiO2 core-shell structure particle

A shell structure and nanotechnology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of increased processing costs, uneven surface coating, environmental pollution, etc., to ensure stability and uniformity , avoid pollution, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

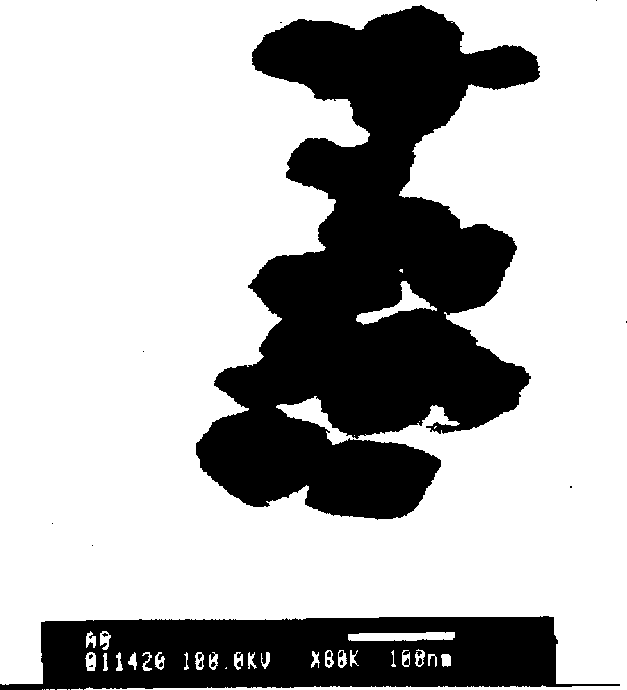

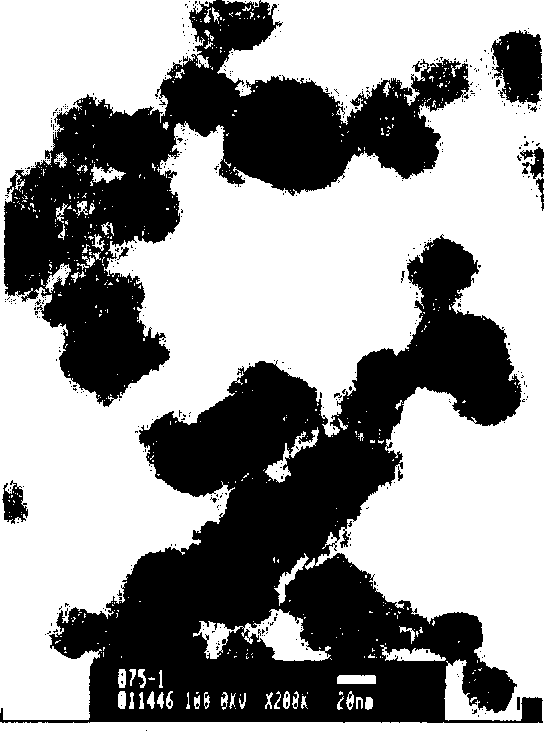

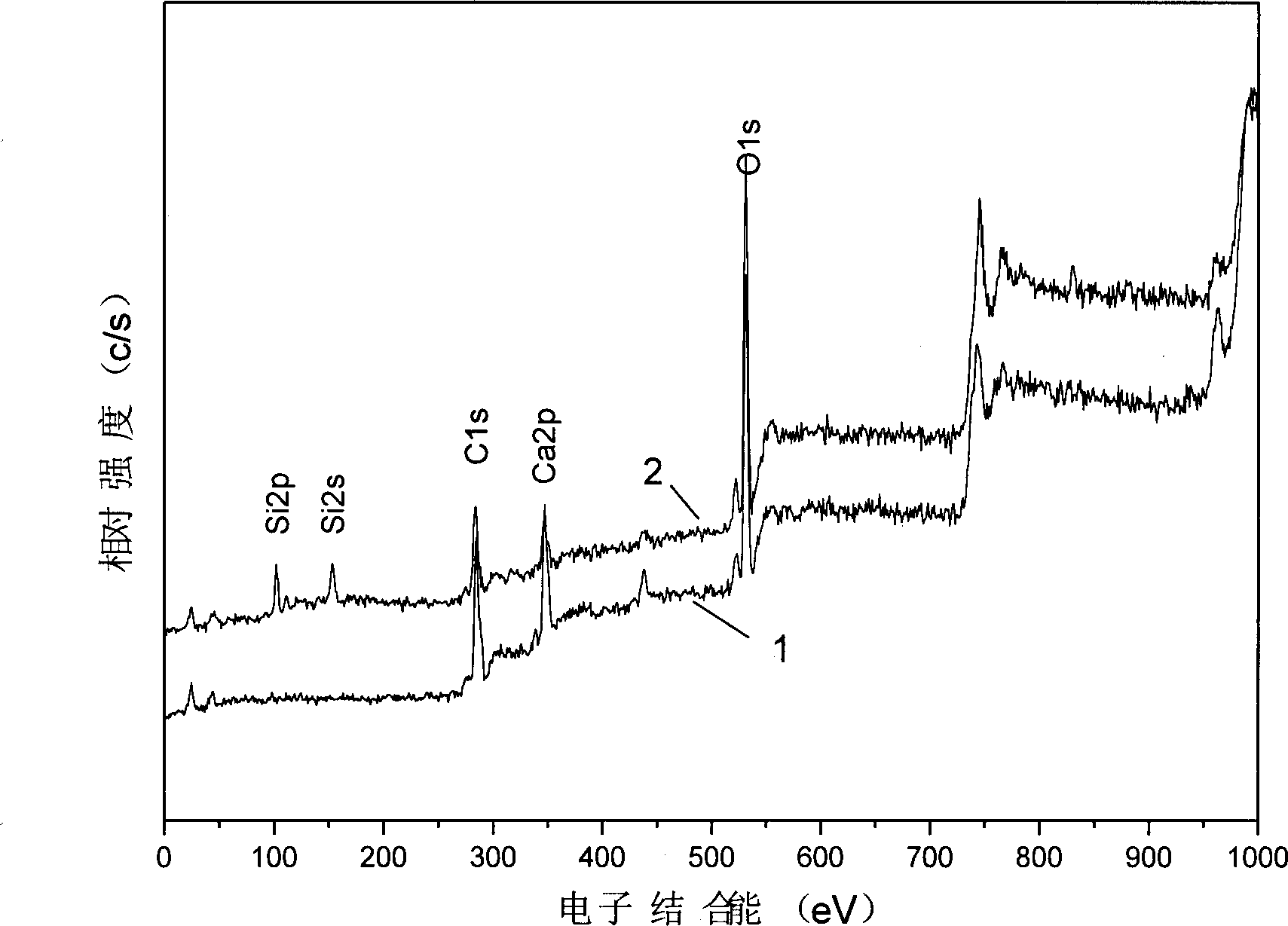

[0020] Filter and wash the nano-calcium carbonate suspension without any surface modification to remove residual ions in the system; add the washed nano-calcium carbonate to a 15% sodium silicate aqueous solution under strong stirring, and ultrasonically disperse Continue to stir for 2 hours after the treatment; put the reaction system in a water bath at 75-80°C, and add H with a concentration of 1mol / L dropwise at a rate of 25ml / min. 2 SO 4 Dilute the solution, control the stirring rate to 4000 rpm, and adjust the pH value of the system to 9.5, and age for 4 hours; the reaction product is cooled, filtered, washed and dried at 120°C to obtain nano-calcium carbonate with a core-shell structure / Silica composite particles. Its size, composition, structure and performance are characterized as follows: the size and surface morphology of composite particles

[0021] From attached figure 1 Pure Nano CaCO 3 It can be seen from the electron microscope photos of the particles that...

Embodiment 2

[0034] In the preparation process of the core-shell structure nano calcium carbonate / silicon dioxide composite particles in Example 1, the lipophilicity inducer ethylene glycol with a water phase mass of 18% was added to the system after ultrasonic treatment, and 5 % organic modifier KH-570, and other conditions remain unchanged. After 60 minutes, the product is cooled, filtered, washed and dried at 120°C to obtain a nano-calcium carbonate / silicon dioxide composite with a core-shell structure hybridized with surface organic matter. particle. Its IR characteristics are as follows:

[0035] 3000~2850cm -1 The absorption peak in the range is the result of the C-H bond stretching vibration absorption of alkanes and alkenes at 1717cm -1 and 1629cm -1 The stretching vibration absorption peaks of the C=O bond and the C=C bond appear at respectively; 1512cm -1 is CH 2 base scissor vibration and CH 3 Base's antisymmetric deformation vibration absorption band, 1395cm -1 The absor...

Embodiment 3

[0037] In the preparation process of the composite particles in Example 1, 15% ethylene glycol and 15% ethanol were added to the water phase after the system was ultrasonically treated, and 15% organic modifier A-151 was added after aging for 3 hours. Material, all the other conditions are constant, and the gained product IR spectrum analysis is as follows:

[0038] 3000~2850cm -1 The absorption peak within the range is due to the absorption of C-H bond stretching vibration on alkanes and alkenes; 1628cm -1 is the stretching vibration absorption of the C=C bond; CH 2 base scissor vibration and CH 3 The anti-symmetrical deformation vibration absorption of the base is at 1510-1400cm -1 at; 1297cm -1 The absorption peak at the Si-O group is the stretching vibration absorption; the antisymmetric stretching vibration absorption peak of the Si-C group appears at 1200-1050cm -1 Within range; 867cm -1 is the symmetrical stretching vibration absorption of Si-O-C bonds; 783cm -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com