Method for preparing aromatic polyurea porous membrane

An aromatic and porous membrane technology, which is applied in the field of preparation of aromatic polyurea porous membranes, can solve the problems of acid and alkali resistance, poor solvent resistance, intolerance to γ-ray irradiation, and low water flux, and achieve mechanical properties and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

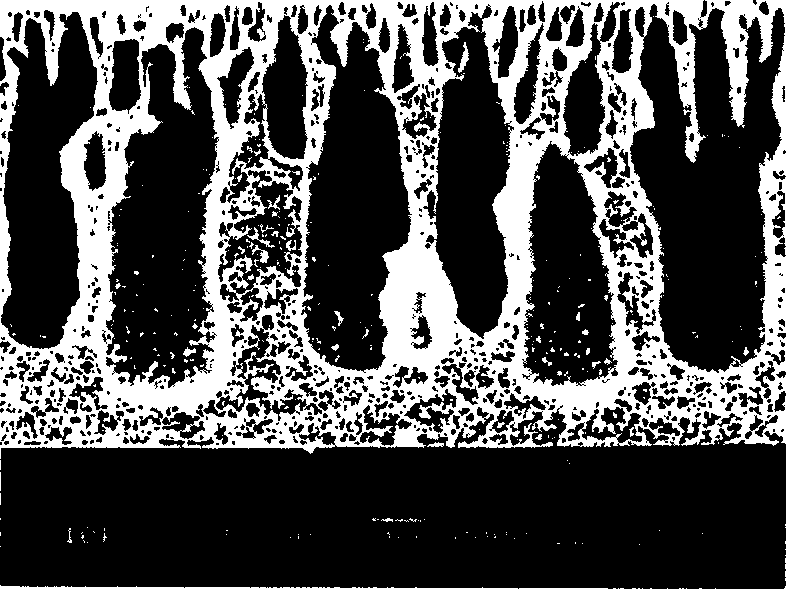

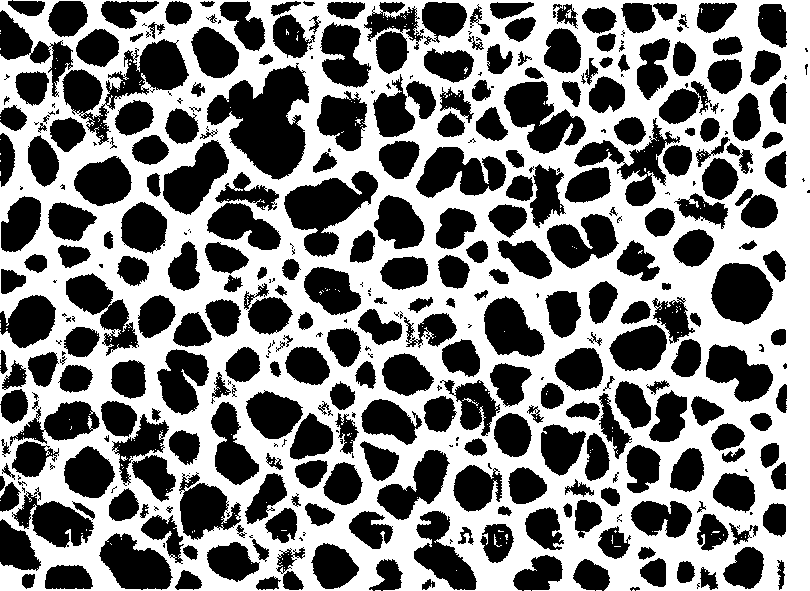

Image

Examples

Embodiment 14

[0030] Embodiment 14,4'-diisocyanate diphenylmethane (MDI)

[0031] 5.0 grams of 4,4'-diisocyanate diphenylmethane (0.02mol) and 28 grams of dimethylacetamide solutions that are dissolved with 1.08 grams of m-phenylenediamine (0.01mol) are successively added in a 250ml three-necked flask, 2 Pre-polymerization was carried out with mechanical stirring. The prepolymerization temperature is controlled at about 55°C, and the prepolymerization is carried out for 30 minutes to obtain a prepolymer with NCO groups at both ends of the molecule.

[0032] Then, a solution of 12 grams of dimethylacetamide dissolved with 1.08 grams of m-phenylenediamine (0.01 mol) was gradually added into the three-necked flask for chain extension reaction. At this time, NCO / NH in the system 2 The molar ratio is 1:1. Stirring was continued at 55° C. for 2 hours to obtain a light yellow transparent viscous polyurea solution with a total solid content of about 16%. Diethylamine was added to block ...

Embodiment 2

[0036] The operation steps are the same as in Embodiment 1. Change the NCO / NH in the reaction system 2 The molar ratio is 1.075:1. The intrinsic viscosity of the obtained product is 0.56dL / g, the breaking strength is 44MPa, the breaking elongation is 7%, and the elastic modulus is 1262MPa; the thermal degradation temperature is about 220°C.

Embodiment 3

[0038] Operation steps are identical with embodiment 1. Change the NCO / NH in the reaction system 2 The molar ratio was 1.2:1, and the polymerization temperature was 60°C. The intrinsic viscosity of the obtained product was 0.42 dL / g, the breaking strength was 68 MPa, the breaking elongation was 17%, and the elastic modulus was 1077 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com