Recording layer dye of recordable disk with high speed

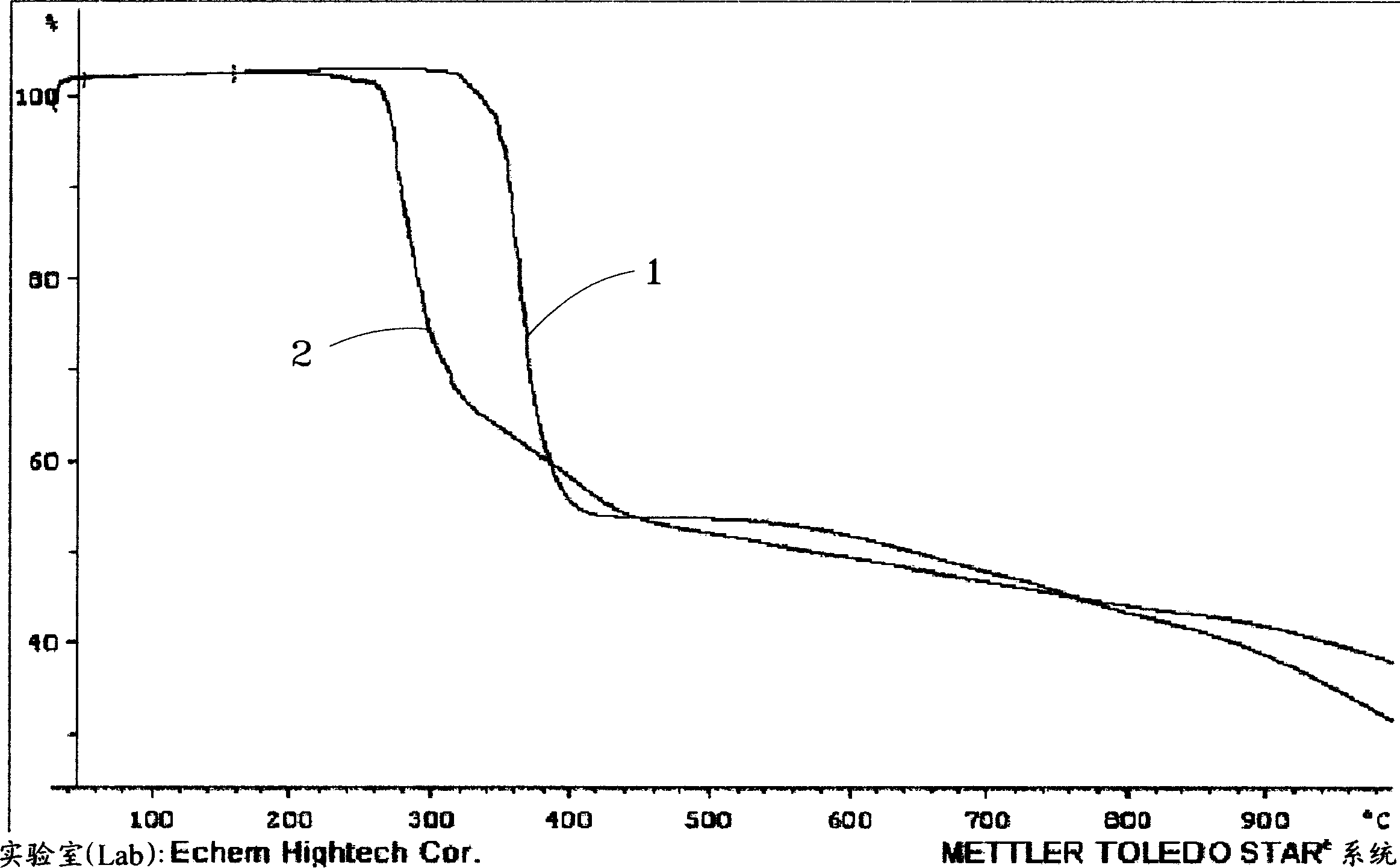

A technology for optical discs and recording layers, applied in the field of phthalocyanine dyes, which can solve the problems of solubility sensitivity, low reflectivity, high jitter rate, and affecting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: the synthesis of phthalocyanine dye

[0022] The present invention is that 10g (7.4mmol) of four-alpha-(alpha-allylborneoxy) copper phthalocyanine (copper tetra-alpha-(alpha-allylborneoxy)phthalocyanine) and 150ml of dichloromethane are placed In a 250ml three-neck round bottom flask, add 0.56g (3.5mmol) of bromine water and stir at room temperature for 1 hour. After the reaction is completed, pour into 10% aqueous sodium bicarbonate solution, add 100ml of dichloromethane for extraction, wash with water, salt out, dry over magnesium sulfate, filter, concentrate under reduced pressure, and use silica gel as a filler for column chromatography to purify. Toluene was used as the eluent; the solid obtained after concentration under reduced pressure was vacuum-dried at 130° C. for 16 hours to obtain 10.5 g of a dark green compound, which was the phthalocyanine dye of the present invention.

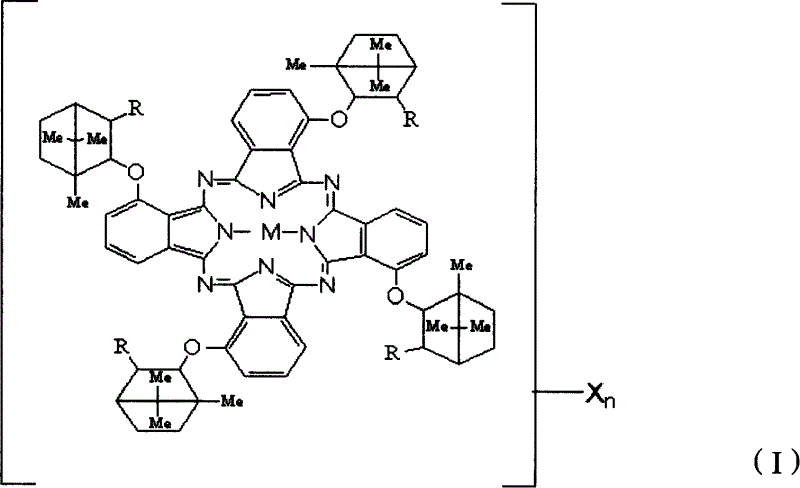

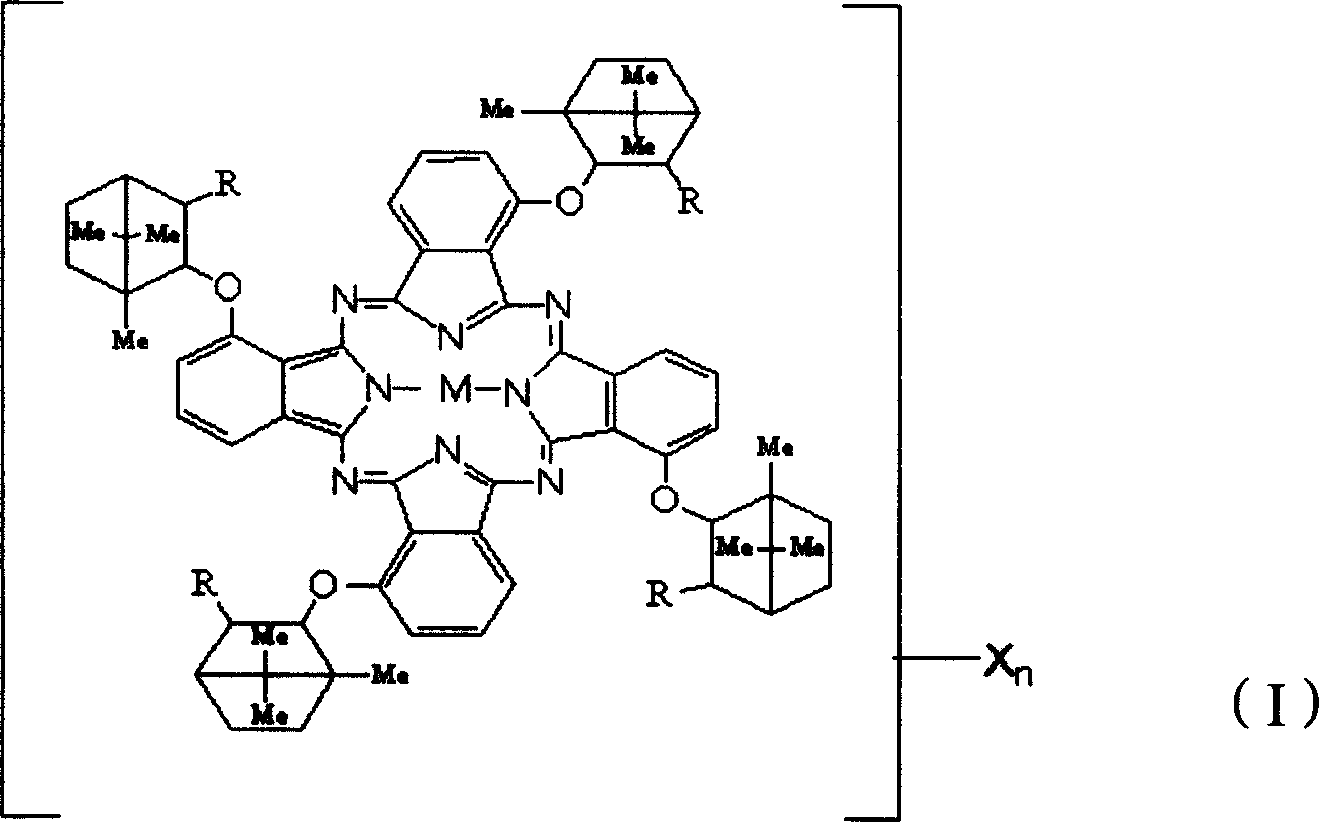

[0023] The known structures of phthalocyanine dyes are as follows:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com