Method and device for light etching micrometer structure of smooth surface

A technology with smooth surface and microstructure, applied in microlithography exposure equipment, photolithographic process exposure devices, electrical components, etc., can solve the problems of short beam coherence length, limited processing accuracy, low absorption rate, etc. , the effect of reducing the area, high performance and price ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

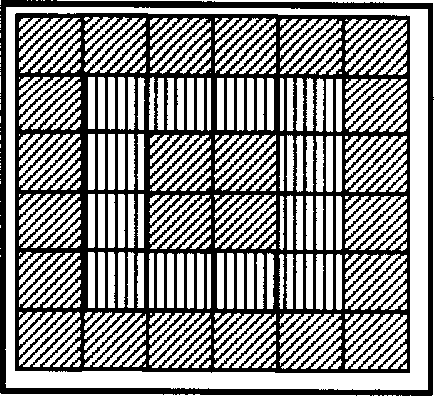

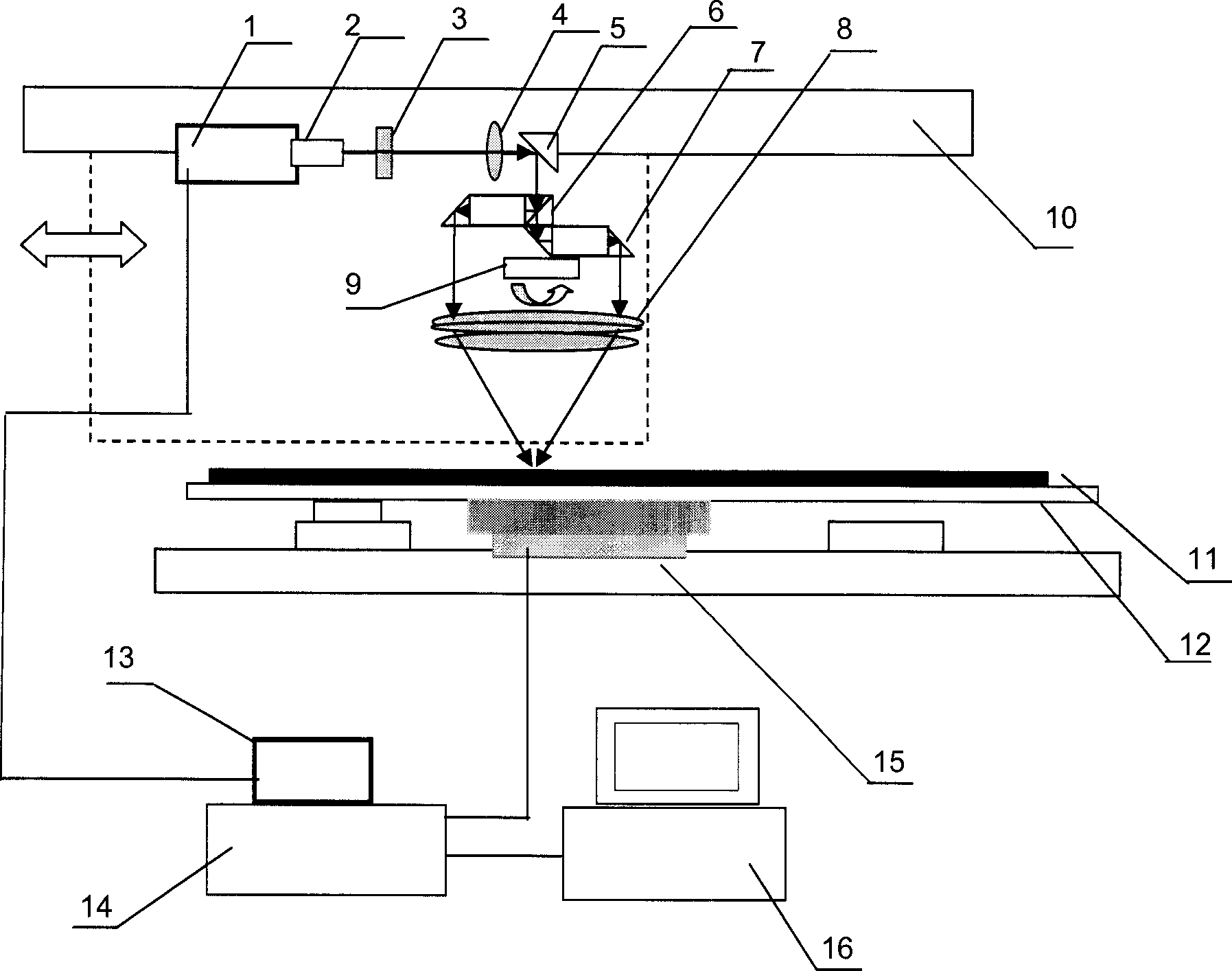

[0061] Embodiment one: see attached figure 2 As shown, a grating image production method converts the image distribution into a pulse control signal. According to the orientation and space frequency of the unit grating, the interference optical head, platform movement, high-speed grating rotation, and optical pulse input are performed at the same time. Continuous exposure on the recording material, the platform, optical head, and beam splitting elements do not need to pause during exposure until the entire image is produced. See the attached Figure 4 .

[0062]The laser lithography direct writing system that realizes the above method includes a DPSSL laser light source 1 output by ultraviolet light with a TTL signal interface, a beam expander collimator mirror 2, an iris diaphragm 3, a quartz lens 4 (objective lens), and a reflector 5 It forms a 4F system together with the quartz lens group 8, and forms a reduced image on the surface of the recording material 11 for the re...

Embodiment 2

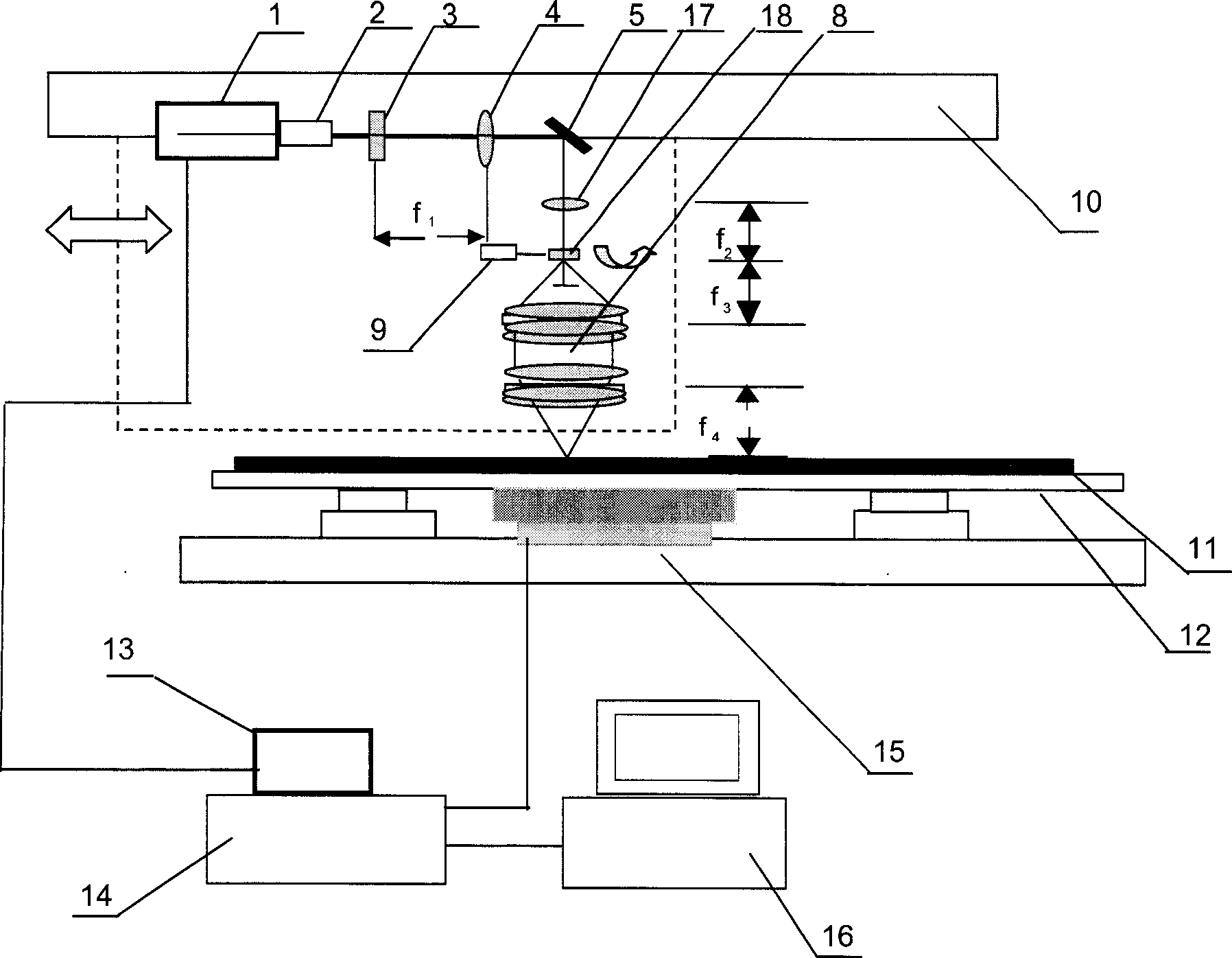

[0065] Embodiment two: see attached image 3 As shown, a photolithography system for making grating images, including laser light source 1, beam expander and collimator mirror 2, variable rectangular diaphragm 3, beam shaping system 4, 5, 17 (lenses f1, f2 The 4F system with the aperture constitutes a miniature function), the beam splitting system (including the beam splitting element quartz phase grating 18, the imaging lens group 8, the high-speed turntable 9), the above-mentioned interference optical The head is assembled on the system 10 of horizontal movement (X direction), the recording material 11 is placed on the working platform 12 (Y direction movement), and the power supply 13 including TTL and power control, the motion system control system 14, 15 and the computer 16.

[0066] The light source 1 can be a pulsed laser light source with ultraviolet output; the rectangular diaphragm can be adjusted. The spectroscopic element is placed on the turntable, and the turnta...

Embodiment 3

[0067] Embodiment 3: A method for making a grating image. First, the image is decomposed into different sub-images according to the orientation of the interference fringes, and each sub-image is continuously exposed. During the exposure of the sub-images, the beam splitting element in the optical head There is no need to rotate, only the beam splitting element is rotated when switching sub-images. This manufacturing method avoids large-angle rotation during continuous operation, and improves the continuity of photolithography operation and the quality of grating image production. See attached Figure 5 .

[0068] The overall structure of the photolithography system in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com