Beta-mannase, its expression and special engineering bacterium

A technology of mannanase and engineering bacteria, applied in genetic engineering, botany equipment and methods, methods based on microorganisms, etc., can solve the problems of complex fermentation process, low enzyme activity, high cost, etc., and achieve simple fermentation process, relatively The effect of high activity and high expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

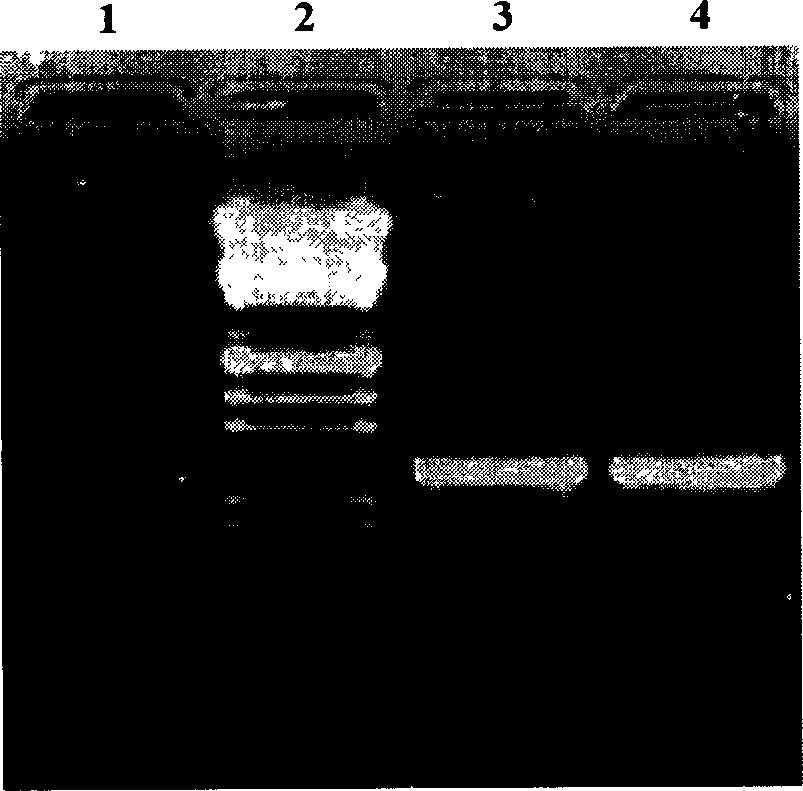

[0044] Embodiment 1, the present invention is derived from the cloning of the β-mannanase gene of Aspergillus thiofucus

[0045] The obtaining of the full-length cDNA sequence of the β-mannanase gene from Aspergillus sulforaphane comprises the following steps:

[0046] 1. Preparation of Aspergillus thiochrome and extraction of total RNA

[0047] Inoculate Aspergillus Sulphureus (Aspergillus Sulphureus, preservation number: CGMCC No.0608) into its growth medium (dissolve 85g wheat bran, 10g bean cake powder, 0.2g KH 2 PO 4 , 0.3g NaCl and 10g sucrose, cook at 121°C for 30min, filter to get the supernatant, aliquot and then autoclave), and culture on a shaker at 30°C for 48h. After the cultivation, the cells were collected by centrifugation at 5000r / min for 1min, and placed in liquid N 2 medium grind. Take 100 mg of the ground bacteria, put it in a 1.5 mL centrifuge tube, add 500 μL RNA extraction buffer (20 mmol / L Tris-HCl, pH 8.0, 1% SDS, 200 mmol / L NaCl, 5 mmol / L EDTA), a...

Embodiment 2

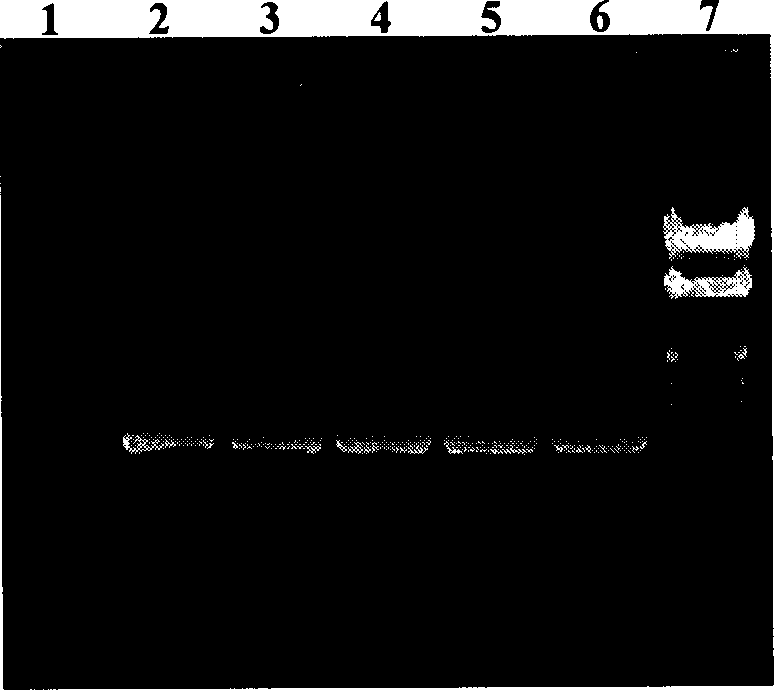

[0068] Embodiment 2, the construction of the expression engineered bacteria of Aspergillus thiochrome β-mannanase

[0069] 1. Construction of Pichia pastoris expression vector for Aspergillus thiochrome β-mannanase gene

[0070] 1. Synthesis of the mature protein gene of Aspergillus thiochrome β-mannanase

[0071] On the premise of not changing the amino acid sequence, only the codons encoding the mature protein in the Aspergillus thiochrome β-mannanase gene cloned in Example 1 were replaced with the preferred codons of Pichia pastoris, thereby obtaining another Aspergillus thiochrome The nucleotide sequence of the β-mannanase gene, that is, the SEQ ID No. in the sequence listing: 3, the SEQ ID No. in the sequence listing: 3 is composed of 1327 bases, and the coding sequence is from the 5' end 25- 1176 bases, encoding a protein with the amino acid residue sequence of SEQ ID №: 1 in the sequence table, bases 1-24 from the 5' end are 5' untranslated regions, bases from 25-87 on...

Embodiment 3

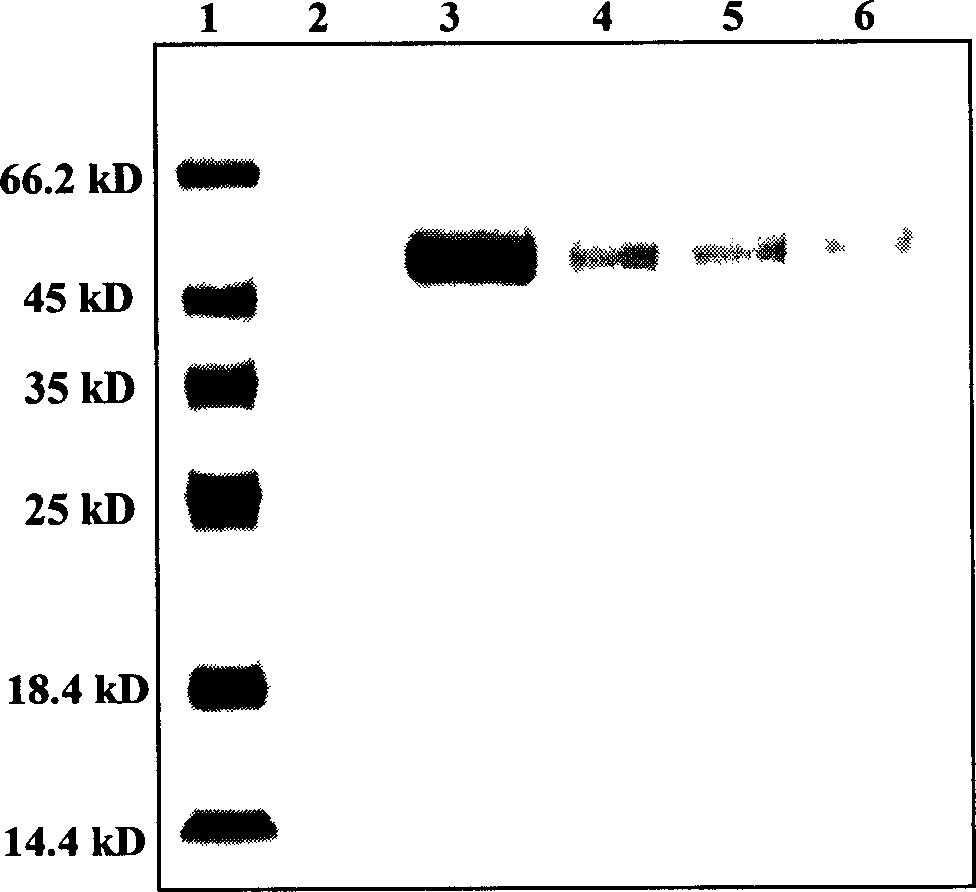

[0083] Example 3, Induced expression of Aspergillus thiochrome β-mannanase

[0084] Pick the recombinant Pichia pastoris yeast strain X-33 / pPIC-Mann obtained in Example 2, inoculate it in a 3L shake flask containing 200mL of BMGY medium, and shake it at 28-30°C and 280rpm for more than 24 hours , get OD 600 About 3.0 seed liquid. Then prepare 4L of BMGY medium, put it into a 10L automatic control fermenter, sterilize it at 121°C, cool it to 28.5°C, add the above seed liquid, adjust the pH to 5.5 with ammonia water and phosphoric acid, and control it by adjusting the speed and air flow. Dissolved oxygen is greater than 30%. It was determined that 23 hours after the seed solution was inserted, the glycerol was completely consumed (dissolved oxygen was marked as 100%), and it entered the stage of feeding 50% (W / V) glycerol at a flow rate of 60 mL / h. After feeding for 4 hours, the glycerin is completely consumed (dissolved oxygen is marked as 100%), and enters the stage of feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com