Method for preparing low molecular weighted glucidamin collagen composition, its product and use

An aminopolysaccharide and collagen technology, which is applied to the preparation of low molecular weight aminopolysaccharide collagen complexes and the fields of products and uses, can solve the problems of poor curative effect, low absorption and utilization rate of aminopolysaccharide biological macromolecules, etc. Use, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of Low Molecular Weight Aminopolysaccharide Collagen Complex Using Chicken Breast Cartilage as Raw Material

[0040] Select 1,000 grams of healthy chicken breast cartilage, remove surface impurities, add water, stir and wash for a few minutes, and drain the turbid water. Cut the cleaned chicken breast cartilage into grain-sized pieces, add 3 liters of water, and grind it finely with a colloid mill to form a viscous suspension. Put the suspension into a constant temperature reaction tank, add trypsin (2-5% by weight of raw materials), keep constant temperature (37±1° C.) for 6-8 hours, and stir once every half hour. After the reaction, the enzymatic hydrolysis reaction solution was heated up to the boiling point (100° C.) for 10 minutes, and then cooled to 37° C.

[0041] Add FeSO to the above enzymatic hydrolysis reaction solution 4 (concentration is 50 micromol / liter) and hydrogen peroxide (concentration is 1500 micromol / liter), react at 37° C....

Embodiment 2

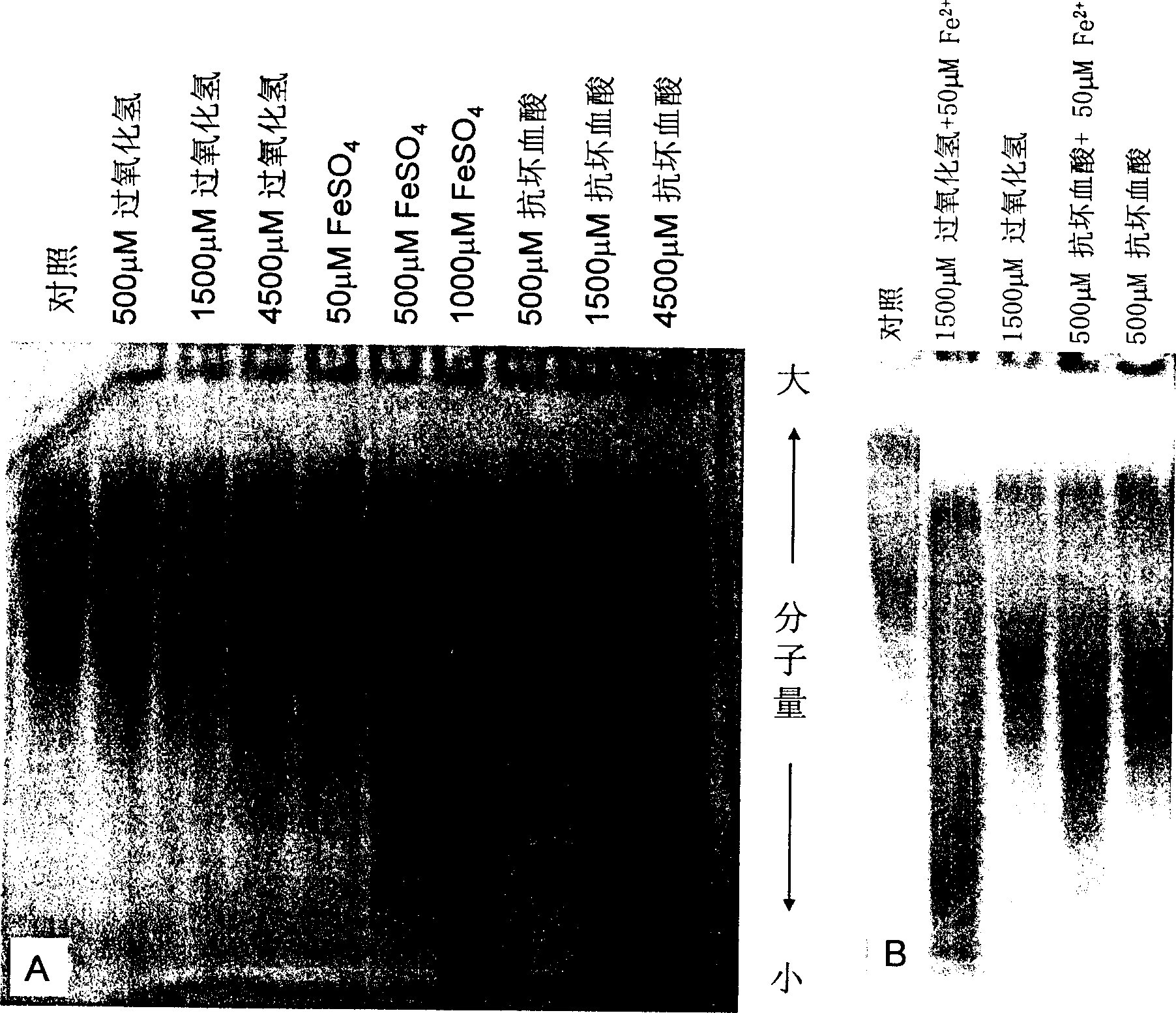

[0043] Embodiment 2: metal ion Fe 2+ , hydrogen peroxide and ascorbic acid on the degradation of amino polysaccharides

[0044] Get several parts of cartilage collagenase hydrolyzate in embodiment 1, add the metal ion Fe of different concentration respectively 2+ , hydrogen peroxide and / or ascorbic acid. The reaction solution was reacted at 37°C for 24 hours or at 50°C for 8 hours. Then 0.3 ml each was sampled and precipitated with 5 volumes of methanol / acetone (2:1) mixture. The aminopolysaccharide precipitate was separated by centrifugation at 12,000g. The precipitate obtained by centrifugation was dried, and then dissolved in 0.1 ml of water to obtain an aqueous aminopolysaccharide solution. Get 7.5 microliters of amino polysaccharide aqueous solution and 7.5 microliters of sample solution (0.2 moles of sucrose-0.089 moles of Tris-0.089 moles of boric acid-0.002 moles of EDTA-0.02% bromophenol blue) mix, then pass through 25% polyacrylamide gel electrophoresis (electrop...

Embodiment 3

[0047] Example 3: Determination of Protein Content in Low Molecular Weight Aminopolysaccharide Collagen Complex

[0048] The determination of the protein content in the low-molecular-weight aminopolysaccharide collagen complex is based on the international regulation method for protein determination - the Kjeldahl method. Accurately weigh 0.2-2.0 grams of samples from batch-produced low-molecular-weight aminopolysaccharide collagen complexes, and use the Kjeldahl method to determine the protein content in the samples. According to the measurement and calculation by this method, the protein content of each batch of cartilage protein complexes is about 63%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com