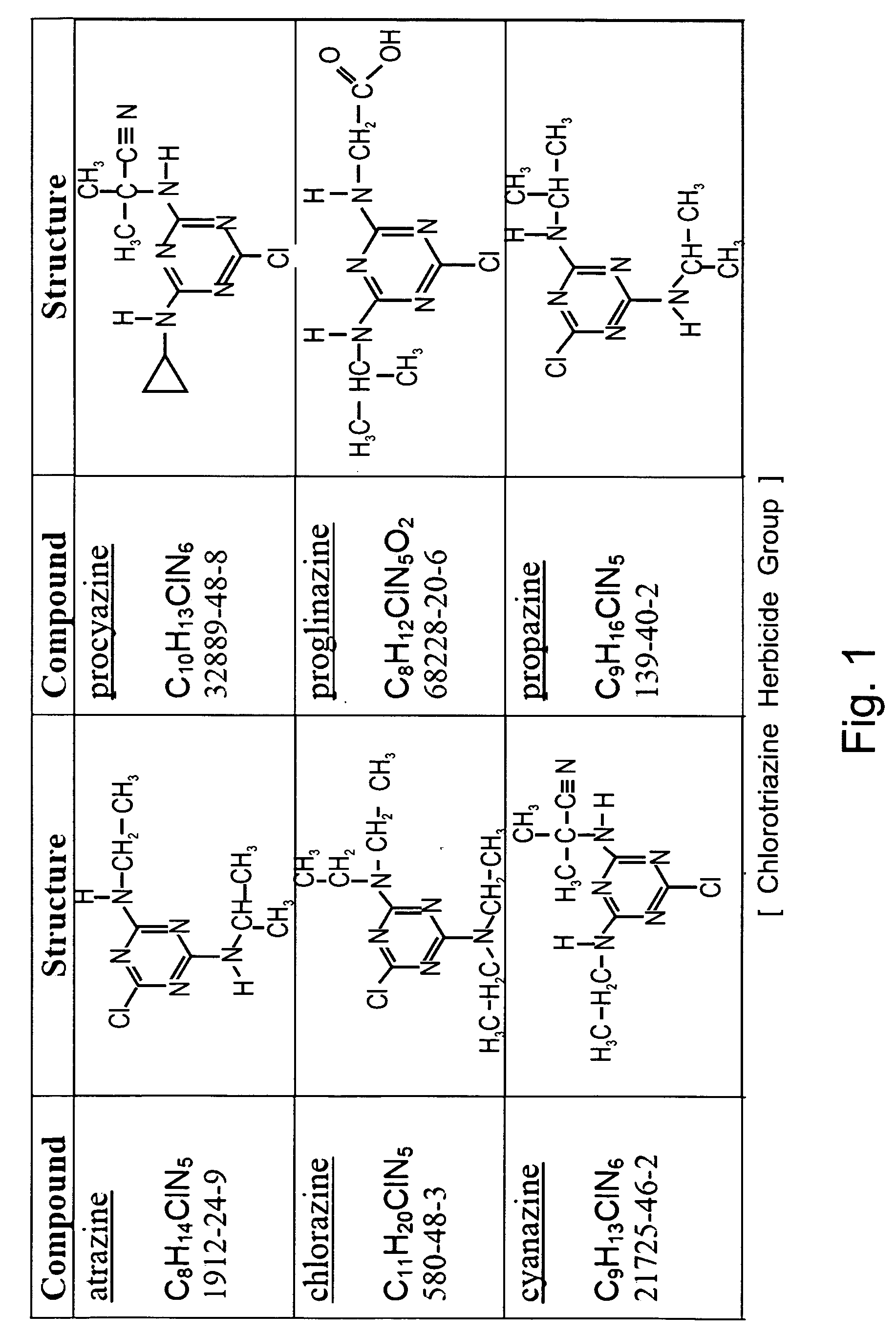

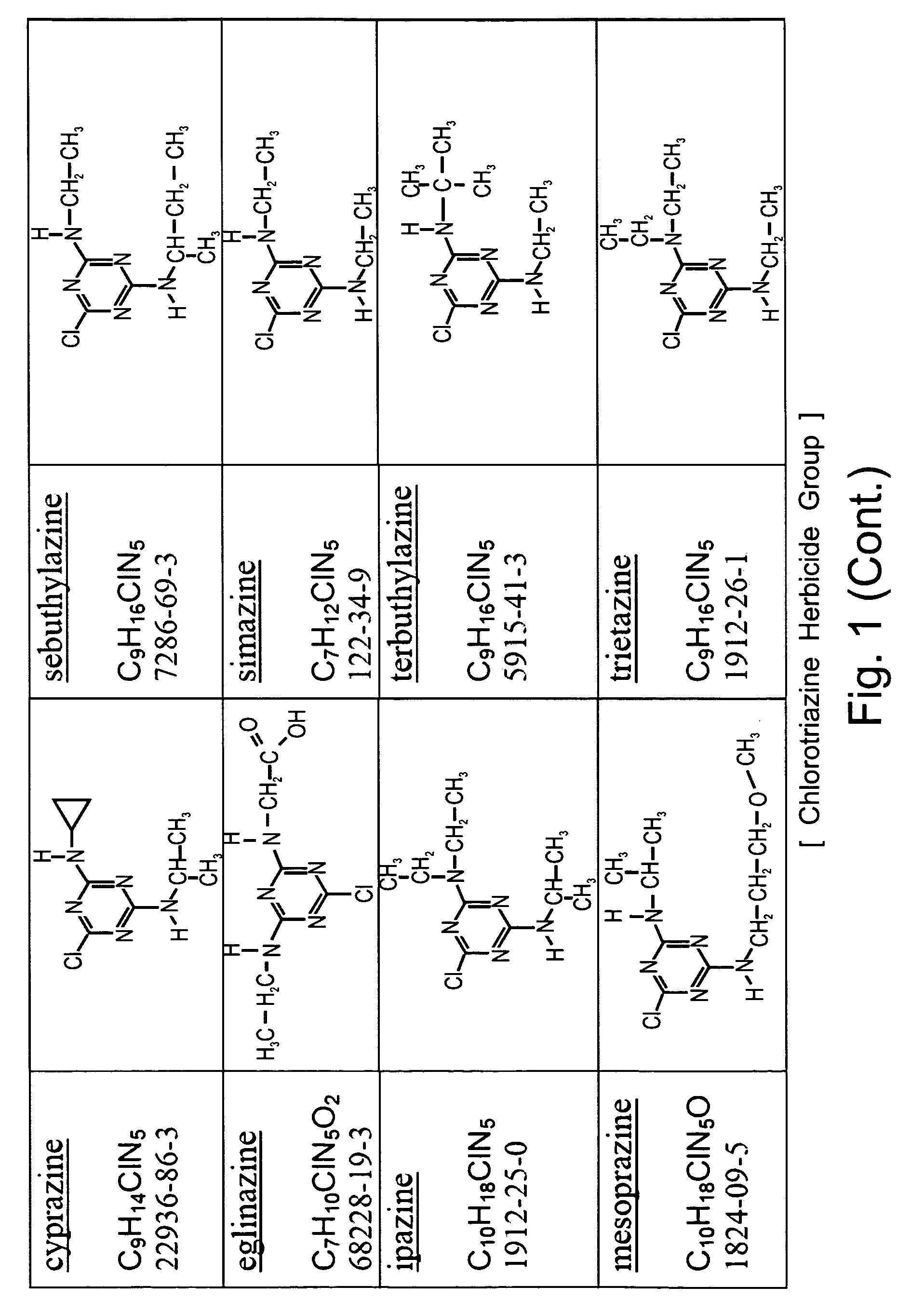

Catalytically Treating Water Contaminated With Halogenated Organic Compounds

- Summary

- Abstract

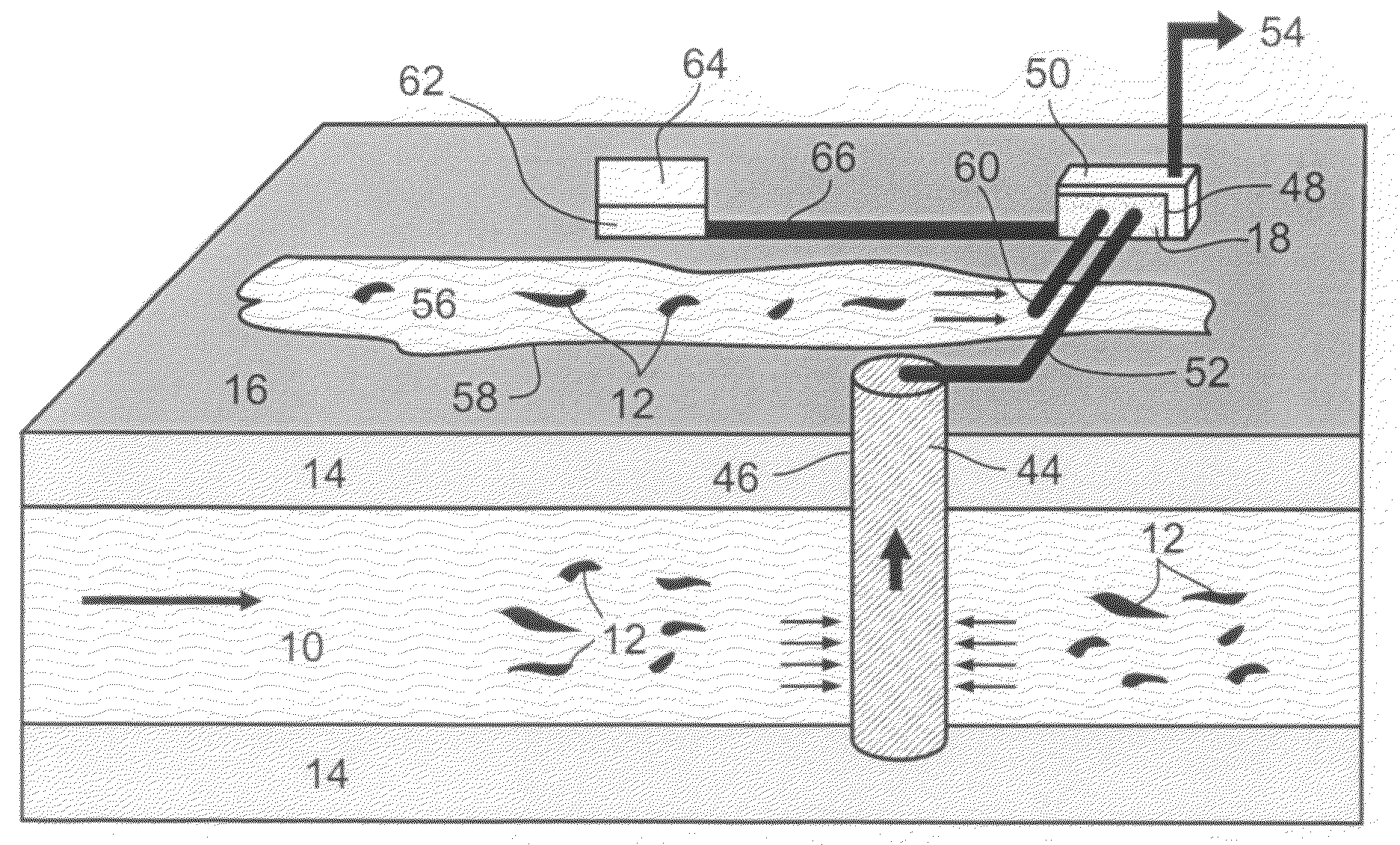

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Catalytically Treating Water Contaminated with Atrazine According to Homogeneous Catalysis Via a Batch Mode

[TMPyP-Ni] Electron Transfer Mediator Catalyst, Zero Valent Iron [Fe0] Bulk Electron Donor

Experimental Procedure

[0355]Example 1 was performed at room temperature (between about 20° C. and about 25° C.) and atmospheric pressure.

[0356]A volume of 500 milliliter (0.5 liter) was taken from the stock solution of water contaminated with atrazine and added to the empty glass beaker (batch reactor), for providing an initial concentration of atrazine of 12 mg atrazine per liter contaminated water, or 12 ppm atrazine in the contaminated water.

[0357]Reducing conditions were not naturally prevalent in the atrazine contaminated water in the glass beaker (batch reactor) for effectively enabling the phenomena, mechanisms, and processes of the electron transfer mediated (homogeneous) catalytic reductive dehalogenation of the atrazine contaminant in the contaminated water. Thus, reducing condit...

example 2

Catalytically Treating Water Contaminated with Atrazine According to Homogeneous Catalysis Via a Batch Mode

[TP(OH)P—Co] Electron Transfer Mediator Catalyst, Titanium (III) Citrate Bulk Electron Donor

Experimental Procedure

[0367]Example 2 was performed at room temperature (between about 20° C. and about 25° C.) and atmospheric pressure.

[0368]A volume of 500 milliliter (0.5 liter) was taken from the stock solution of water contaminated with atrazine and added to the empty glass beaker (batch reactor), for providing an initial concentration of atrazine of 12 mg atrazine per liter contaminated water, or 12 ppm atrazine in the contaminated water.

[0369]Reducing conditions were not naturally prevalent in the atrazine contaminated water in the glass beaker (batch reactor) for effectively enabling the phenomena, mechanisms, and processes of the electron transfer mediated (homogeneous) catalytic reductive dehalogenation of the atrazine contaminant in the contaminated water. Thus, reducing cond...

example 3

Catalytically Treating Water Contaminated with Atrazine According to Homogeneous Catalysis Via a Batch Mode

[TMPyP-Co] Electron Transfer Mediator Catalyst, Titanium (III) Citrate Bulk Electron Donor

Experimental Procedure

[0377]Example 3 was performed at room temperature (between about 20° C. and about 25° C.) and atmospheric pressure.

[0378]A volume of 25 milliliter (0.025 liter) was taken from the appropriate stock solution of water contaminated with atrazine and added to the empty 40 milliliter glass vial (batch reactor), for providing an initial concentration of atrazine of 28 mg atrazine per liter contaminated water, or 28 ppm atrazine in the contaminated water. This procedure was repeated, for preparing at least two glass vials (batch reactors) for each sampling point.

[0379]Reducing conditions were not naturally prevalent in the atrazine contaminated water in the glass vials (batch reactors) for effectively enabling the phenomena, mechanisms, and processes of the electron transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Substance count | aaaaa | aaaaa |

| Substance count | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com