Use of nitrogen compounds quaternised with alkylene oxide and hydrocarbyl-substituted polycarboxylic acid as additives in fuels and lubricants

a technology of hydrocarbohydrate and nitrogen compounds, which is applied in the direction of fuels, organic chemistry, mechanical apparatus, etc., can solve the problems of engine performance, engine performance, engine performance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

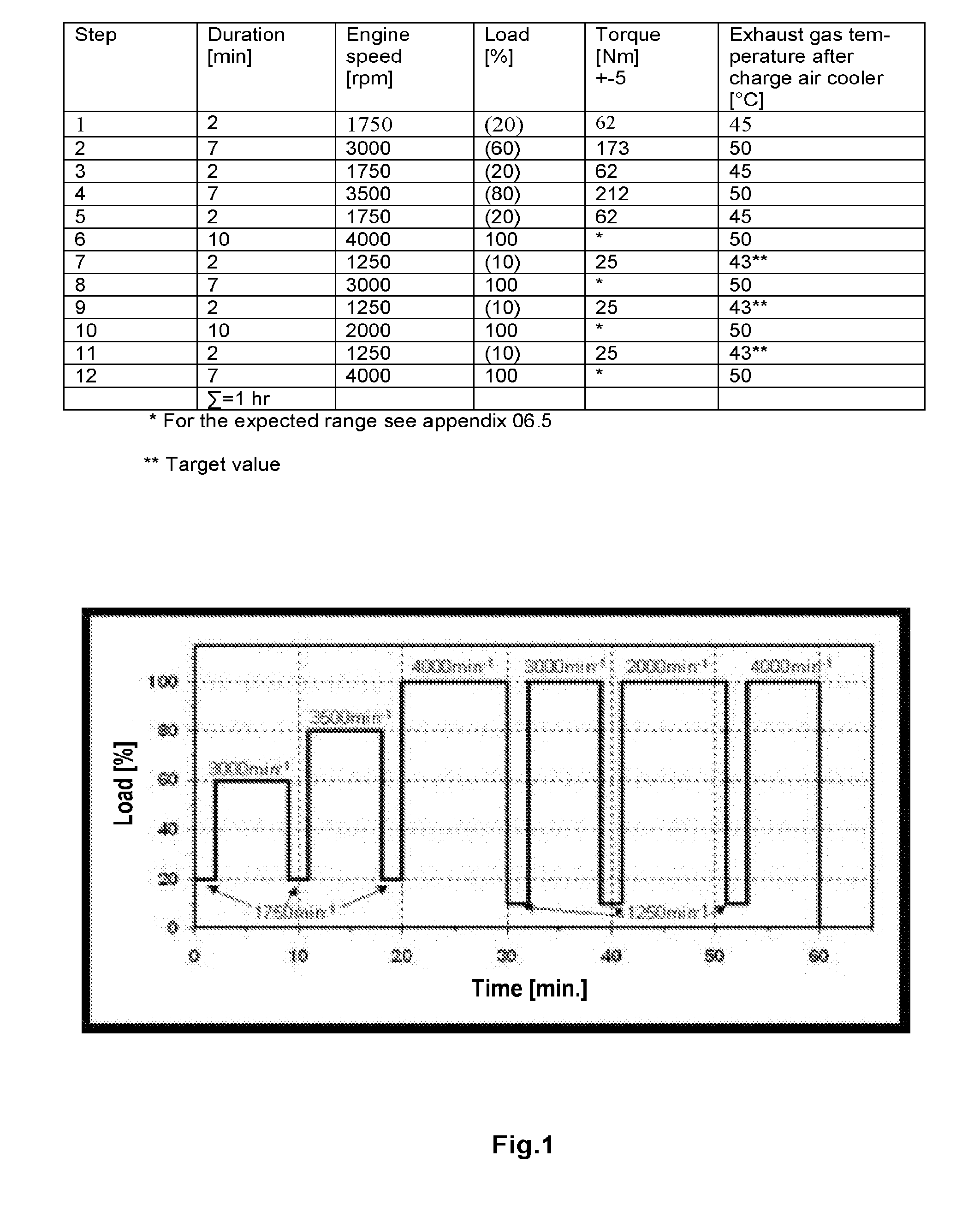

Method used

Image

Examples

preparation examples

B. Preparation Examples

Preparation Examples 1 to 4

Quaternization of Tertiary Fatty Amines with Propylene Oxide in the Presence of Various Hydrocarbyl-Substituted Succinic Acids

[0341]

[0342]R1 here represents long-chain hydrocarbyl; R2, R3 and R4 correspond to Ra, Rb and Rc as defined above; R5 corresponds to Rd as defined above; and R is H or a radical obtained by esterification with the epoxide, for example —CH2CH(R5)OH

a) Reagents Used:

[0343]Polyisobutylenesuccinic anhydride (PIBSA, Glissopal® SA, from BASF): Prepared from maleic anhydride and Polyisobutene 1000 in a known manner. Unless stated otherwise, for the inventive preparation examples, qualities having a bismaleation level of 10% to 20% and hydrolysis numbers in the range of 84-95 mg KOH / g were used. For preparation of polyisobutylenesuccinic acid, polyisobutylenesuccinic anhydride was admixed with the equimolar amount of water in accordance with the hydrolysis number and hydrolyzed at a temperature of 80° C. For example, t...

preparation example 5

Quaternization of Triethylamine with Dodecene Oxide in the Presence of Tetrapropenylsuccinic Acids

[0350]Reagents: dodecene oxide (CAS 2855-19-8) from Aldrich, trimethylamine (anhydrous, CAS 75-50-3) from BASF

[0351]An N2-inertized 2 l autoclave is initially charged with a solution of trimethylamine (47.2 g, 0.8 mol) and dodecene oxide (147.2 g, 0.8 mol) in 2-ethylhexanol (194.4 g). Subsequently, the temperature is increased to 40° C. A solution of tetrapropenylsuccinic acid (252.8 g, 0.8 mol) in 2-ethylhexanol (252.8 g) is metered in within 1.5 h. This is followed by stirring at 40° C. for 15 h. Volatile constituents are removed by introducing an N2 stream at 40° C., then the reactor is emptied. 1H NMR (CDCl3) confirms the quaternization (6=3.3 ppm, singlet, RN(CH3)3).

preparation example 14

Synthesis of iC13NMe2

[0352]Tridecylamine (140.2 g) is initially charged at room temperature and formic acid (166.7 g) is added while stirring within 15 min. The reaction mixture is heated to 45° C. and aqueous formaldehyde solution (37%; 132.7 g) is added dropwise with evolution of CO2 within 25 min. Subsequently, stirring is continued at 80° C. for 23 h. After cooling to room temperature, hydrochloric acid (32%; 121.5 g) is added while stirring. The mixture is stirred at room temperature for 3 h and the water is removed on a rotary evaporator under reduced pressure. 500 mL of water are added to the product mixture, and 50% sodium hydroxide solution is used to release the amine. The mixture was extracted twice with methyl tert-butyl ether, the combined organic phases were dried over sodium sulfate and the solvent was removed on a rotary evaporator. The product (143.5 g) exhibited a total amine number of 228 mg KOH / g with 94% tertiary amine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent mass | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com