Instrument for electrosurgical tissue treatment

a tissue treatment and electrosurgical technology, applied in the field of electrosurgical tissue treatment, can solve the problems of tissue desiccation or destruction at the contact point of the patient's tissue, cell destruction, tissue damage or destruction, etc., and achieve the effects of low resistivity, low thermal conductivity, and minimal heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

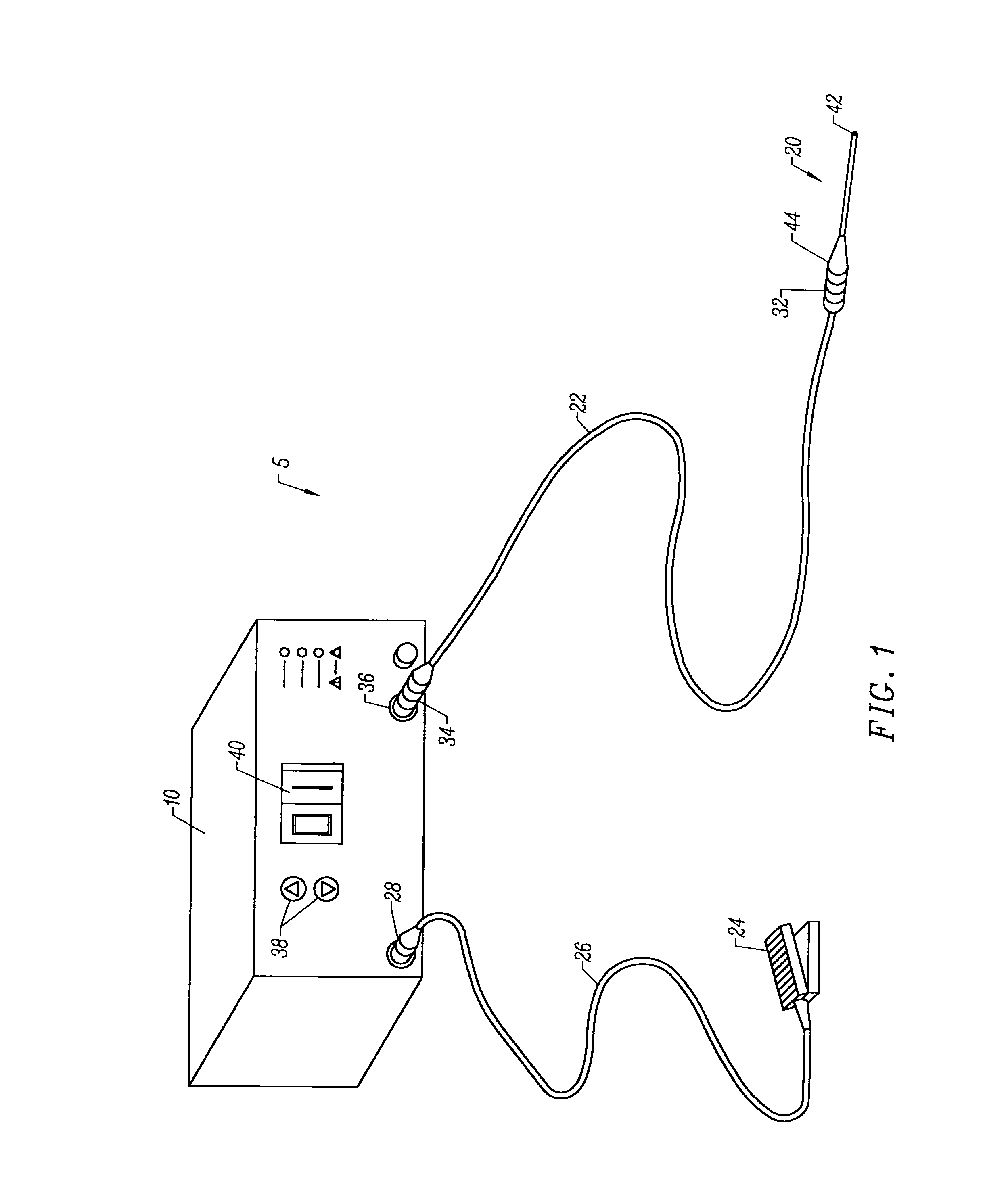

[0057]In the present invention, high frequency (RF) electrical energy is applied to one or more active electrodes in the presence of electrically conductive fluid to remove and / or modify body tissue. The techniques of the present invention may be performed in a conventional open surgery environment or in a minimally invasive manner using cannulas or port access devices. The present invention is useful in procedures where the tissue site is flooded or submerged with an electrically conducting fluid, such as arthroscopic surgery of the knee, shoulder, ankle, hip, elbow, hand or foot. Specifically, the present invention is useful in the resection and / or ablation of the meniscus and the synovial tissue within a joint during an arthroscopic procedure. In addition, tissues which may be treated by the system and method of the present invention include, but are not limited to, prostate tissue and leiomyomas (fibroids) located within the uterus, gingival tissues and mucosal tissues located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com