Method for preparing Nano material of lead tungstate

A technology of nanomaterials and lead tungstate, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effect of convenient raw material acquisition, regular shape and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare 1mol / L Pb(NO 3 ) 2 100ml aqueous solution and 1mol / L NaWO 4 100ml of aqueous solution (the reagents used are all analytical alcohols). Take 1ml each and add it to a 100ml beaker for mixing, then add 0.001mol CTAB (cetyltrimethylammonium bromide), then add a certain amount of deionized water and stir at room temperature for about 1 hour, then transfer into 50ml polytetrafluoroethylene In the ethylene reactor, add deionized water to the reactor to 60%-65% of the volume of the reactor, seal it, and react at 120° C. for 3 hours. The reaction kettle was naturally cooled to room temperature.

[0025] (2) The product is taken out, washed 7-8 times with deionized water and absolute ethanol, centrifuged and dried, and the final product is dispersed in absolute ethanol to obtain the desired product.

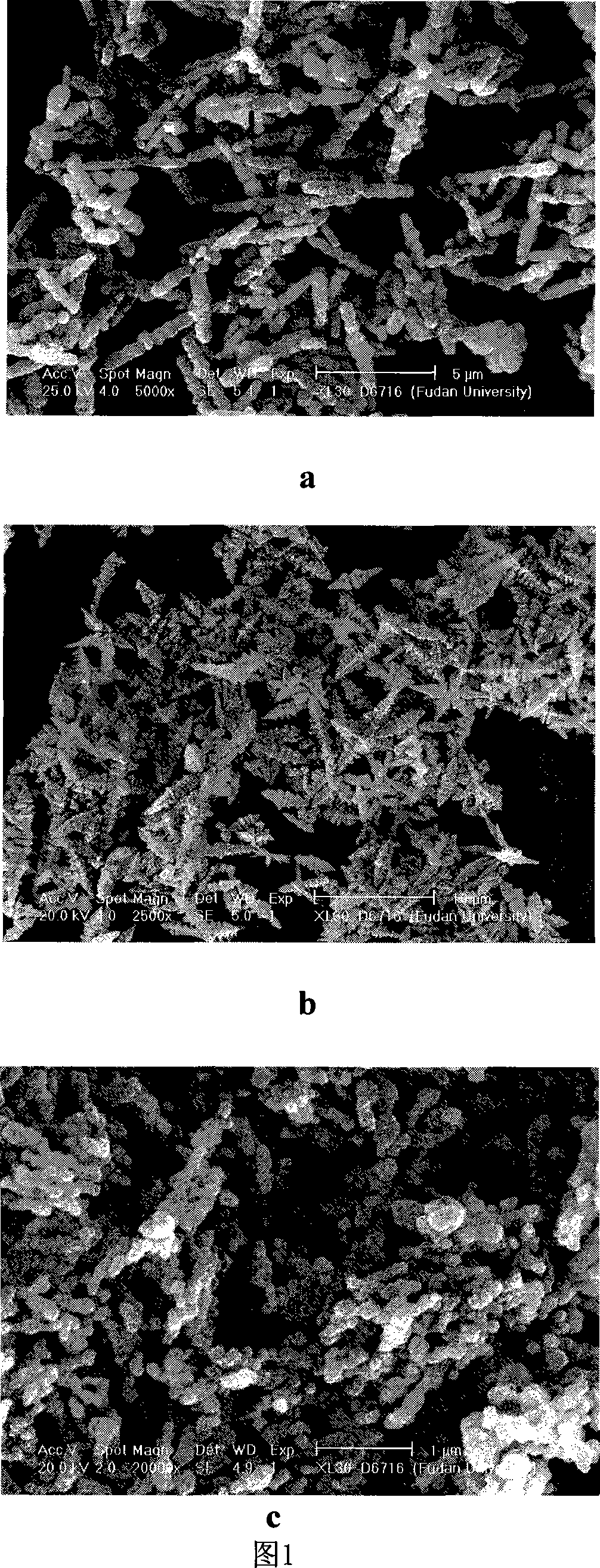

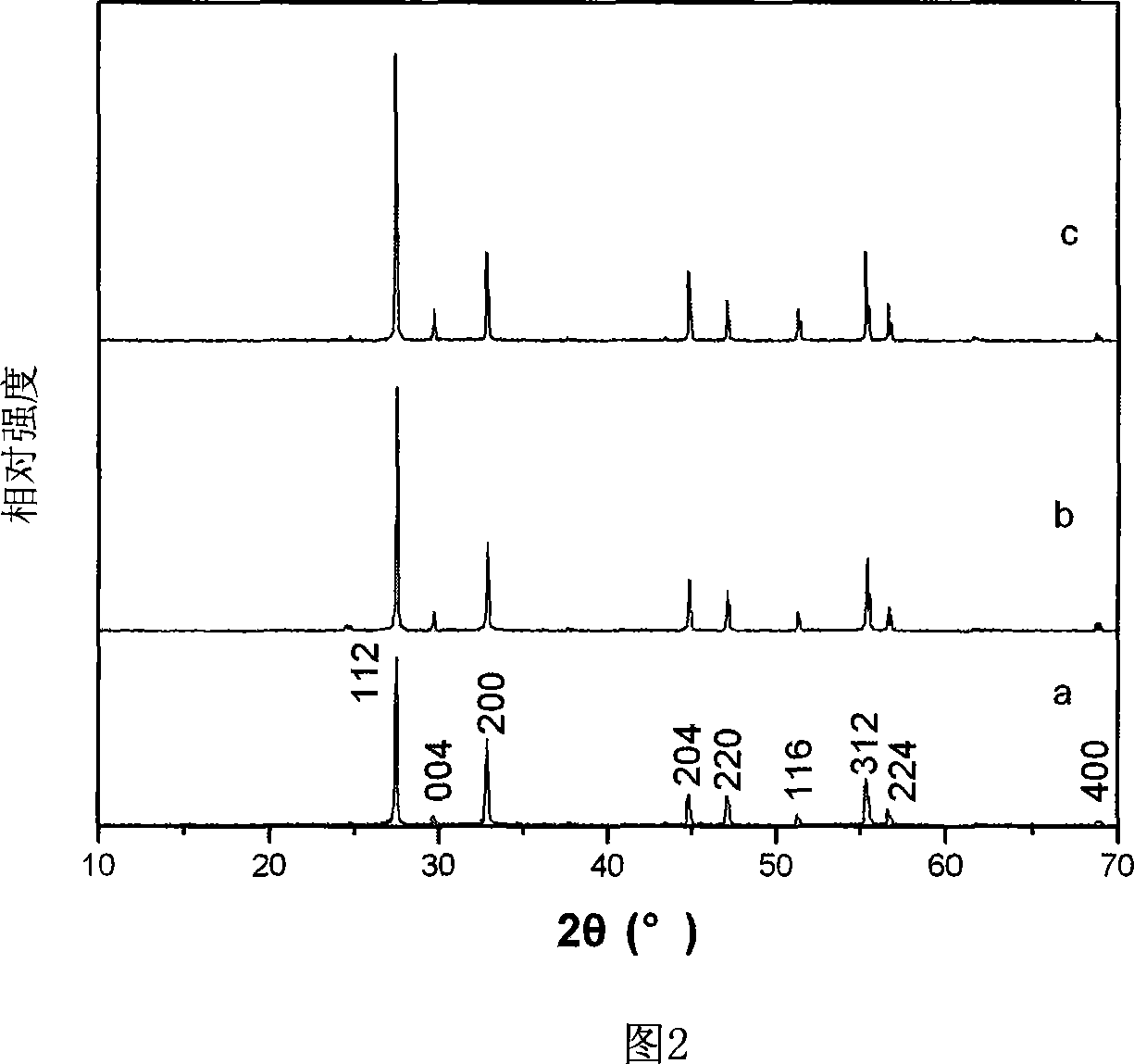

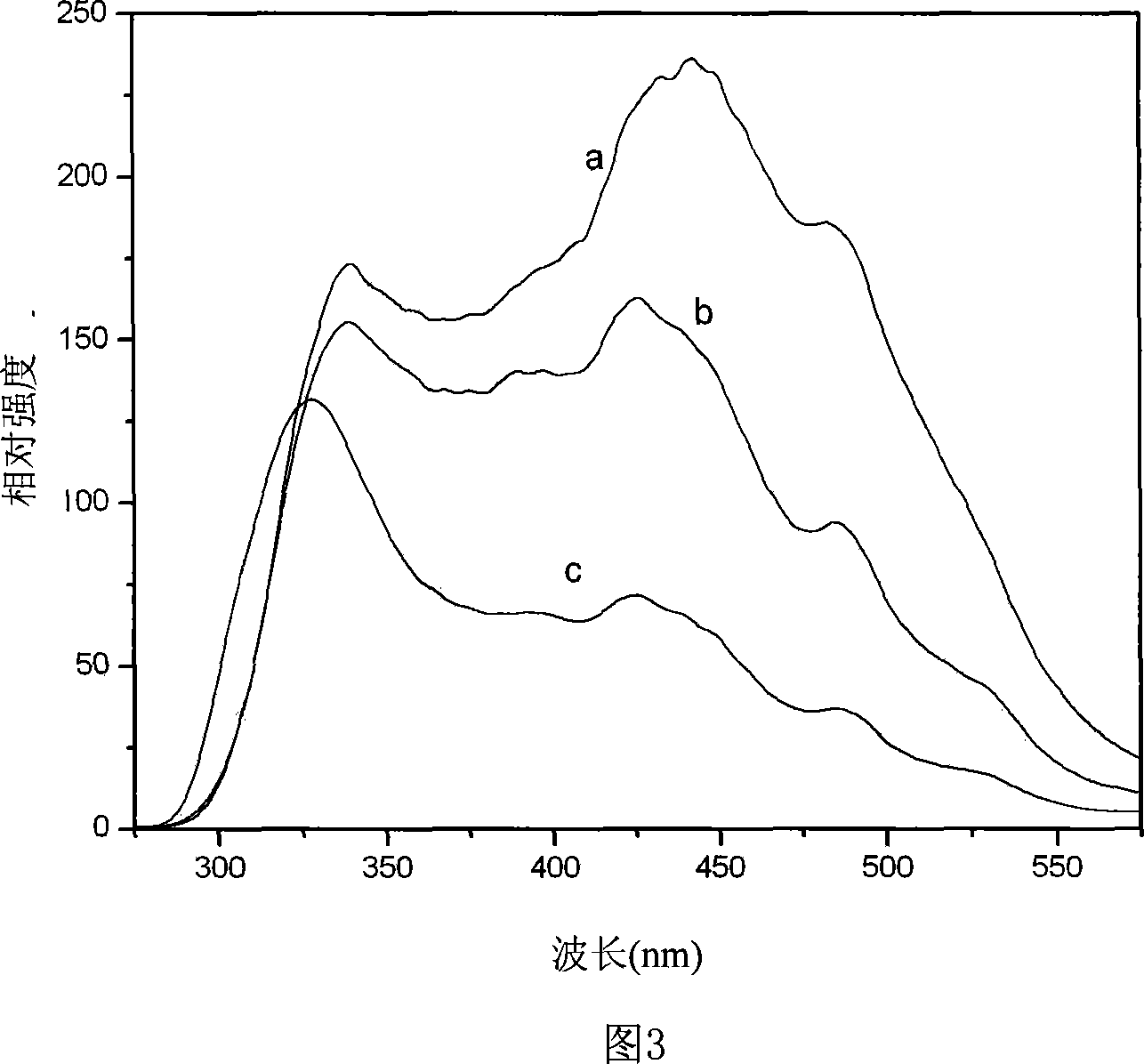

[0026] The morphology and structure of the product were characterized by scanning electron microscopy (SEM) and X-ray powder diffractometer (XRD). It can be seen fro...

Embodiment 2

[0028] Prepare 1mol / L PbAc respectively 2 Aqueous solution 100ml and 1mol / L NaWO 4 100ml of aqueous solution (the reagents used are all analytical alcohols). Take 1ml each and add it to a 100ml beaker for mixing, then add 0.002mol SDS (hexadecyltrimethylammonium bromide), then add a certain amount of deionized water and stir at room temperature for about 1 hour, then transfer into 50ml polytetrafluoroethylene In the ethylene reactor, add deionized water to the reactor to 65%-70% of the volume of the reactor, seal it, and react at 140° C. for 6 hours. The reaction kettle was naturally cooled to room temperature. The product is taken out, washed 3-6 times with deionized water and absolute ethanol, centrifuged and dried, and the final product is dispersed in absolute ethanol to obtain the desired product. The obtained product is pagoda-shaped PbWO 4 Quasi-nanometer material, the crystal system of the product is the same as in Example 1. The product has high purity and good c...

Embodiment 3

[0030] Prepare 1mol / L PbCl respectively 2 Aqueous solution 100m and 1mol / L NaWO 4 100ml of aqueous solution (the reagents used are all analytical alcohols). Take 0.8mlPbCl respectively 2 aqueous solution and 1ml NaWO 4 Put the aqueous solution into a 100ml beaker, then add 0.0015mol CTAB (cetyltrimethylammonium bromide), then add a certain amount of deionized water and stir at room temperature for about 1 hour, then move it into a 50ml polytetrafluoroethylene reactor , add deionized water to the reactor to 60%-63% of the volume of the reactor, seal it, and react at 160° C. for 12 hours. The reaction kettle was naturally cooled to room temperature. The product was taken out, washed with deionized water and absolute ethanol, centrifuged and dried, and the final product was dispersed in absolute ethanol to obtain the desired product. , the obtained product is PbWO with a diameter of about 150 nm 4 Nanoparticles, the crystal system of the product is the same as in Example 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com