Composite ferroelectric film and low-temperature preparation method thereof

A ferroelectric thin-film, low-temperature technology, used in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficulty in meeting the requirements of micro-devices, high crystal growth temperature, affecting film performance, etc., to reduce leakage current, The effect of low preparation temperature and improved fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

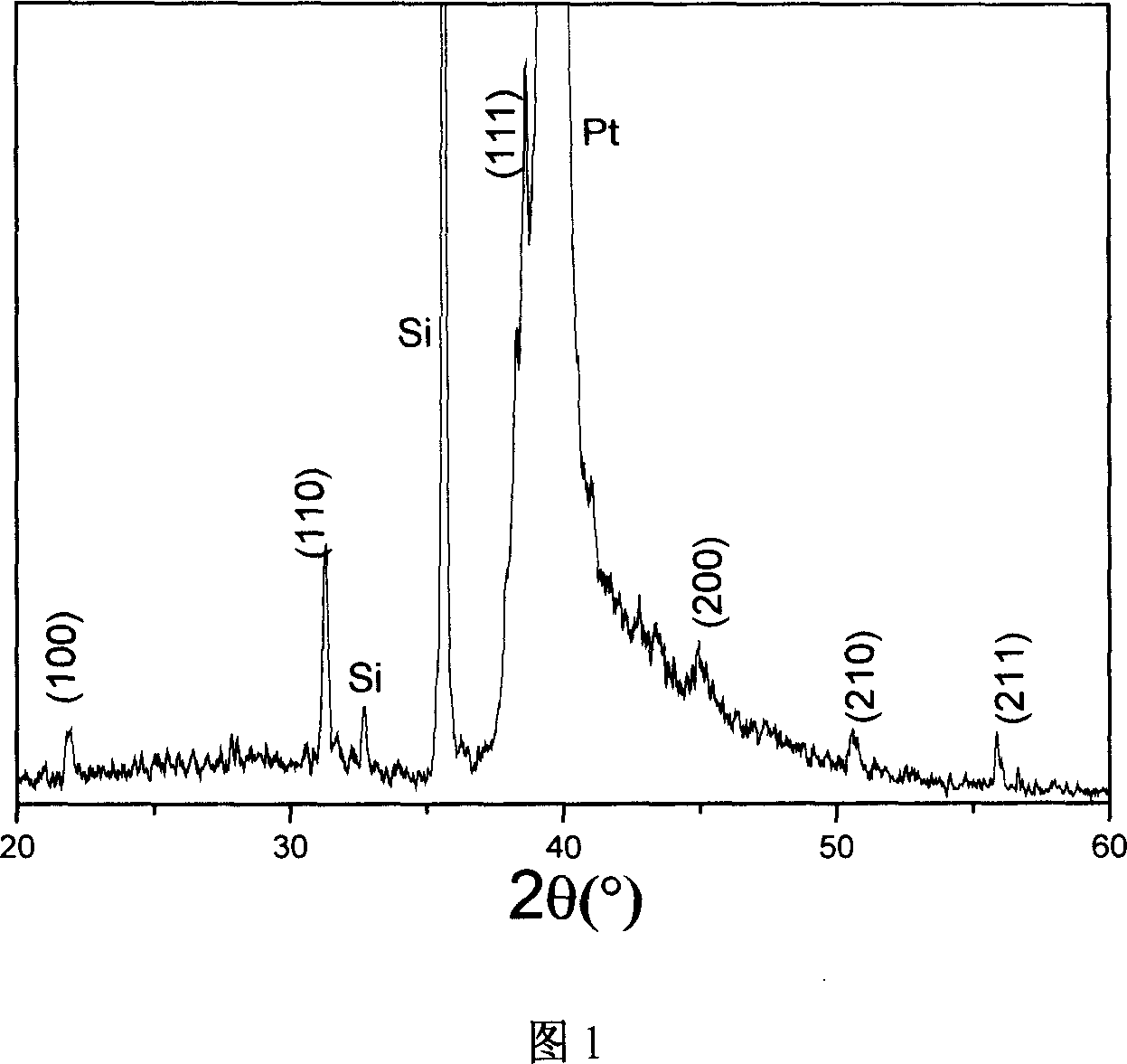

[0017] Embodiment 1: prepare BaTiO 3 Ferroelectric thin film

[0018] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2 ] and titanium isopropoxide [Ti(OC 3 h 7 ) 1 ], the solvent is glacial acetic acid and ethylene glycol ether. First heat barium acetate (according to a certain stoichiometric ratio) in glacial acetic acid solution to boiling, stop heating after 5 minutes, and cool to room temperature, the molar ratio of Ba to glacial acetic acid is 1:10. Then add the mixed solution of titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) into the barium-containing glacial acetic acid solution, wherein: the molar ratio of Ti to AcAc is 1:2, titanium isopropoxide: ethylene diacetone The molar ratio of alcohol to ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentration of the final solution to 0.3M. After standing for 24 hours, it was used to prepare the film.

[0019] The substrate used is Pt / Ti / SiO 2 / Si...

Embodiment 2

[0021] Embodiment 2: preparation (Ba x Sr 1-x )TiO 3 , (x=0-0.9) ferroelectric thin film

[0022] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2 ], strontium acetate [Sr(CH 3 COO) 4 ] and titanium isopropoxide [Ti(OC 3 h 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. First heat barium acetate and strontium acetate (according to a certain stoichiometric ratio x=0.10) in glacial acetic acid solution to boiling, stop heating after 10 minutes, and cool to room temperature, the molar ratio of Ba+Sr to glacial acetic acid is 1: 10. Then the mixed solution of titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) is added to the glacial acetic acid solution containing barium and strontium, wherein: the molar ratio of Ti to AcAc is 1: 2, titanium isopropoxide and The molar ratio of ethylene glycol ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentration of the final solution to 0.3M. ...

Embodiment 3

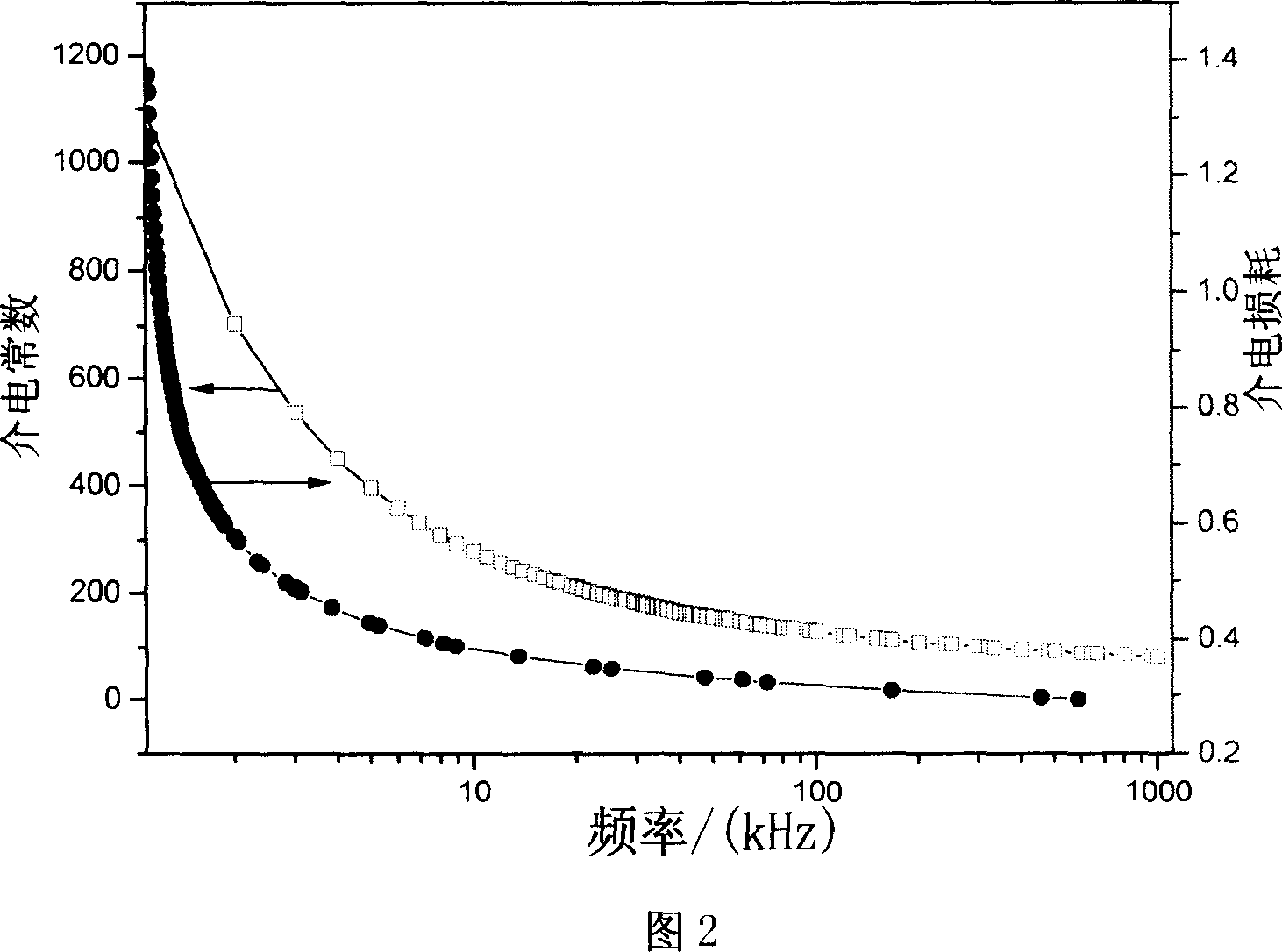

[0025] Embodiment 3: preparation (Ba x Sr1-x )TiO 3 , (x=0-0.9) ferroelectric thin film

[0026] The film prepared by the sol-gel method is the same as in Example 2, the temperature of the hydrothermal treatment is changed to 300°C, and the immersion time is 12 hours. The film after hydrothermal treatment was placed in an autoclave at 100°C, the pressure of pure oxygen was 8 MPa, and it was taken out after heat treatment for 20 hours. Finally, a gold electrode was sputtered on the upper surface by DC sputtering method as the upper electrode, and its diameter was 0.5 mm, the thickness is about 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com