Method for synthesizing silicon nitride nano material under low temperature by solvent hot reaction

A technology of solvothermal reaction and nanomaterials, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of high reaction temperature and inability to obtain crystalline Si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Prepare β-Si by reacting sodium azide, magnesium powder and silicon tetrachloride 3 N 4 Nanorod-based silicon nitride powder

[0024] Take 1g of sodium azide, 0.5g of magnesium powder and 10mL of silicon tetrachloride, put them into a special stainless steel 18mL reaction kettle, use nitrogen to remove the air in the kettle, seal it and place it in a resistance crucible boiler, and make three groups at 200°C ±5°C, 250°C±5°C, 300°C±5°C for 10 hours; after stopping heating, cool the reactor to room temperature naturally; Separation and drying, that is obtained as β-Si 3 N 4 Nanorod-based silicon nitride powder products. Vacuum-dried at 50°C for 6 hours to obtain an off-white powder product.

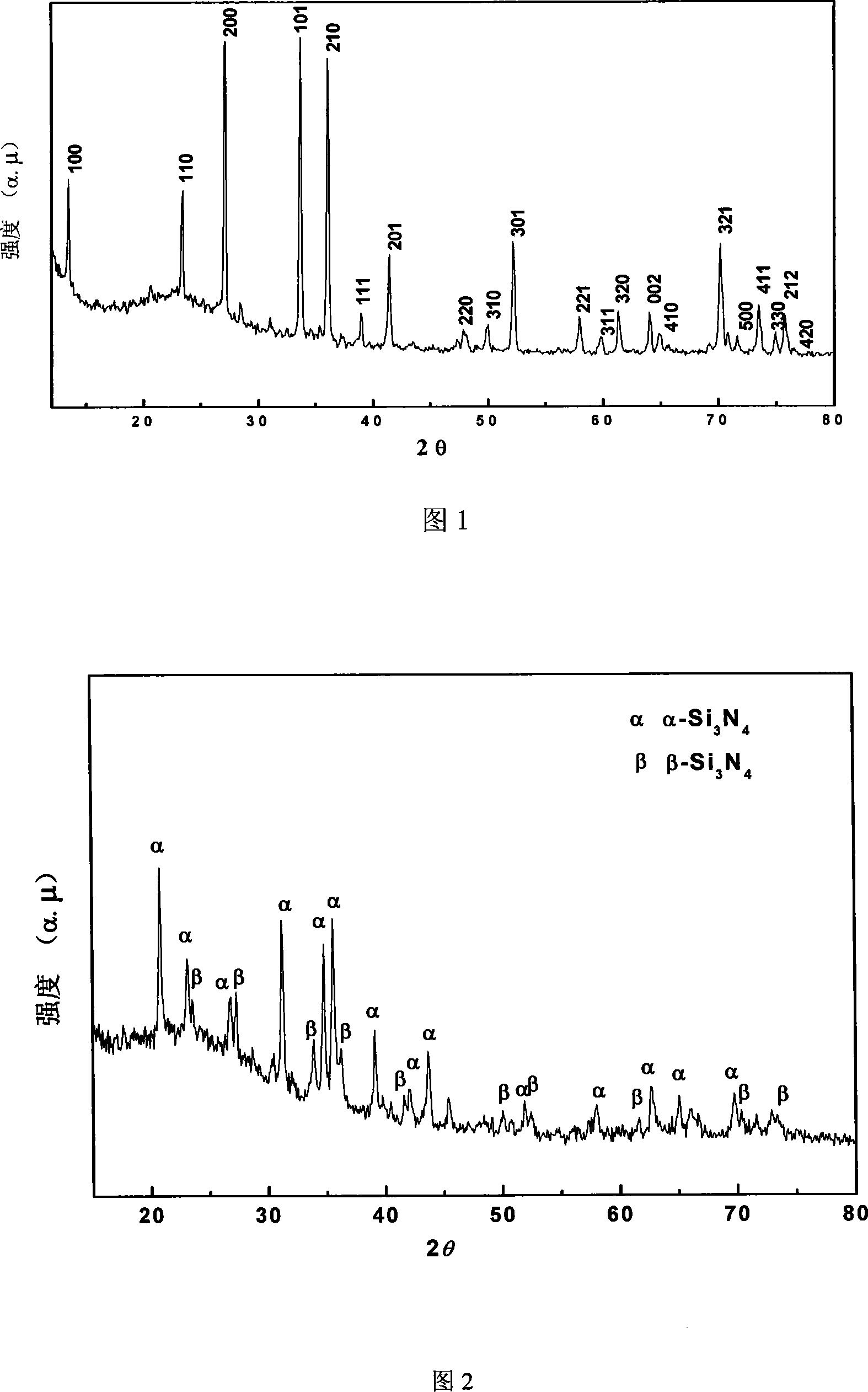

[0025] Cu Kα rays (wavelength The scanning step speed is 0.08° / sec) as the diffraction light source for X-ray diffraction analysis of the product.

[0026] Fig. 1 is the X-ray diffraction spectrum of the product prepared by reacting sodium azide, magnesium powder a...

Embodiment 2

[0027] Example 2: Preparation of α-Si by reacting sodium azide, iron powder and silicon tetrachloride 3 N 4 Nanowire based silicon nitride powder

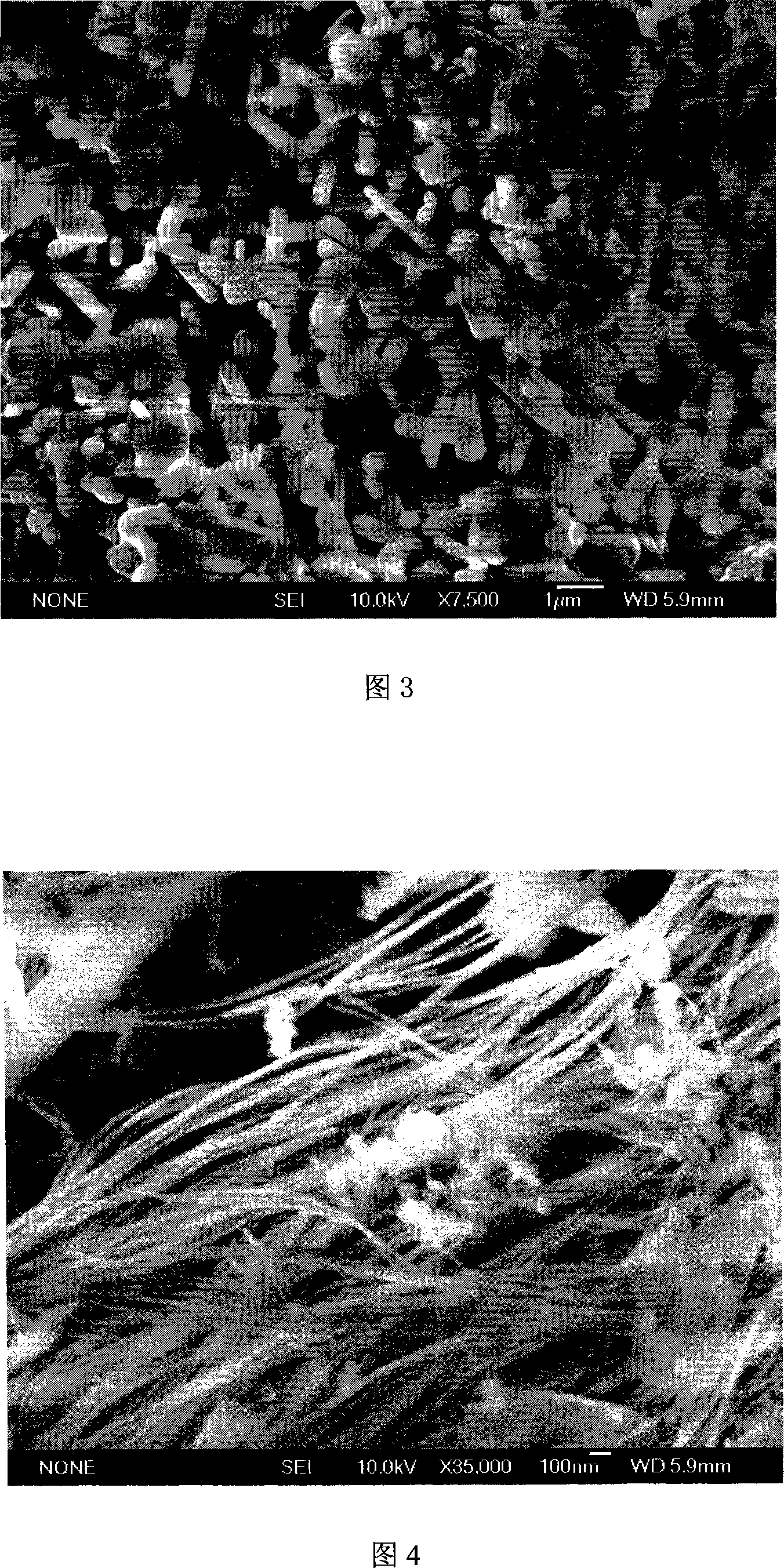

[0028] SiCl was added in a molar ratio of 5.8:1:0.58 4 , NaN 3 Mixed with iron powder, sealed in an autoclave, and reacted at 250 ° C for 10 hours; the product was pickled, washed with water, centrifuged and dried to obtain α-Si 3 N 4 Nanowire-based silicon nitride powder. The results are shown in Figure 2.

[0029] Figure 2 shows the α-Si prepared by using metal iron powder as reducing agent at 250°C 3 N 4 X-ray diffraction spectrum (XRD) of the nanowire-dominated silicon nitride product. It can be seen from the figure that the sample is α-Si 3 N 4 and β-Si 3 N 4 mixed phase.

Embodiment 3

[0030] Example 3: Comparison of the effects of various metal additives on the experiment (as shown in Figure 9)

[0031] It is found that only metal magnesium powder, calcium particles and aluminum powder can generate β-Si at low temperature 3 N 4 It has a promoting effect, especially magnesium powder has the best effect; metal iron powder, sodium and nickel powder have the effect of producing α-Si at low temperature. 3 N 4 There is a promoting effect.

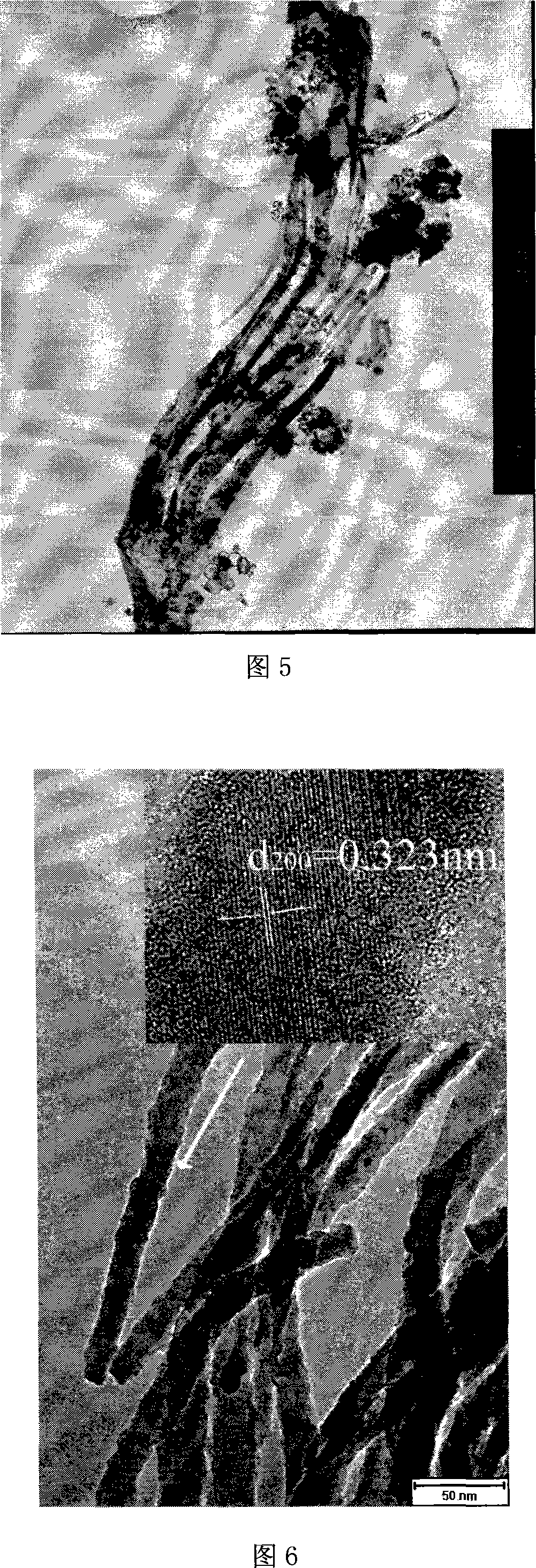

[0032] The morphology and particle size of the product were observed using H700 transmission electron microscope (TEM) and JSM-6700F scanning electron microscope (SEM):

[0033] It can be seen from Fig. 3, the SEM photo of the product, that the nanowire micrographs with different contrasts show that the nanorods are uniform in thickness and 100-800 nm in diameter. Figure 4 is the Si prepared in Mode 2 3 N 4 SEM photo of nanowires, with diameters of 30-125 nanometers and lengths of tens of micrometers. FIG. 5 is a TEM ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com