Glucomannan enzyme preparation method

A technology of glycanase and glucomannan, which is applied in the field of glucomannanase preparation, can solve the problems of limited access to glucomannan oligosaccharides, and achieve the effects of easy extraction and purification, high enzyme activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

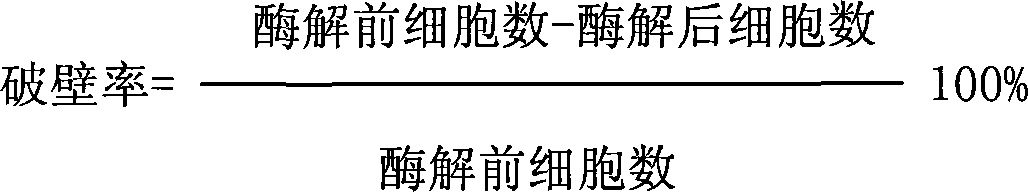

Method used

Image

Examples

Embodiment 1

[0020] Mix 6 g of bagasse, 1 g of bran, 0.5 g of konjac fine powder, 1.5 g of agar, 2 g of ammonium sulfate, 1 g of potassium dihydrogen phosphate, 0.05 g of magnesium sulfate, and 100 g of water to make a test tube slant culture medium and sterilize it. Trichodermaviride CGMCC3.2942 bred by ultraviolet mutagenesis was inoculated into the above slant culture medium, cultured at 28° C. for 4 days, and 150 mL of spore suspension was obtained.

[0021] Bagasse 73g (73%), bran 15g (15%), yeast cell wall 10g (10%), konjac powder 2g (2%) are mixed to obtain a solid medium, ammonium sulfate 1.1g, potassium dihydrogen phosphate 0.11g , 0.055g of magnesium sulfate and 218.735g of water are mixed to obtain 220g of nutrient salt water. Take 100 g of the solid koji culture medium obtained by mixing the solid medium and nutrient saline (mass ratio 1:2.2), put it in a 1000 mL Erlenmeyer flask, sterilize it, add 8 mL of spore suspension, shake it well, and culture it at a constant temperatur...

Embodiment 2

[0027] Mix 6 g of bagasse, 1 g of bran, 0.5 g of konjac fine powder, 1.5 g of agar, 1 g of yeast cell wall, 2 g of ammonium sulfate, 1 g of potassium dihydrogen phosphate, 0.05 g of magnesium sulfate, and 100 g of water to make a test tube slant medium, bacteria. Trichoderma viride CGMCC3.2942 selected by ultraviolet mutagenesis was inoculated into the above-mentioned slant medium, cultured at 28°C for 4 days, and 150 mL of spore suspension was obtained.

[0028] Bagasse 65g (65%), bran 20g (20%), yeast cell wall 12g (12%), konjac powder 3.0g (3%) were mixed to obtain a solid medium, ammonium sulfate 1.035g, potassium dihydrogen phosphate 0.1035 g, magnesium sulfate 0.046g, mixed with water 228.8155g to obtain 230g of nutrient salt water. Take 100 g of the solid koji culture medium obtained by mixing the solid medium and nutrient saline (mass ratio 1:2.3), put it in a 1000 mL Erlenmeyer flask, sterilize it, insert 15 mL of the spore suspension, shake it up and culture it at 3...

Embodiment 3

[0035] Bagasse 6g, bran 1g, konjac fine powder 0.5g, agar 1.5g, yeast cell wall 1g, ammonium sulfate 2g, potassium dihydrogen phosphate 1g, magnesium sulfate 0.05g, mix with water 100g, make test tube slant culture medium, kill bacteria. Trichoderma viride (Trichoderma viride) CGMCC3.2942 bred by ultraviolet mutagenesis was inoculated into the slant medium, cultured at 28° C. for 4 days, and 150 mL of spore suspension was obtained.

[0036]Bagasse 66g (66%), bran 15g (15%), yeast cell wall 15g (15%), konjac powder 4g (4%) are mixed to obtain a solid medium, ammonium sulfate 1.38g, potassium dihydrogen phosphate 0.138g , magnesium sulfate 0.069g, mixed with water 228.413g to obtain 230g of nutrient salt water. Get 100 g of the solid koji culture medium obtained by mixing the solid medium and nutrient saline (mass ratio 1:2.3), put it in a 1000mL Erlenmeyer flask, sterilize it, insert 8mL of the spore suspension, shake it up and culture it at a constant temperature at 27°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com