Macromolecule polymer and method for preparing the polymer and nano fibre thereof

A high molecular polymer and nanofiber technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of functional polymer antibacterial performance failure, human body or environmental hazards, etc., and achieve universal antibacterial pollution Antibacterial properties, good antibacterial performance, long-term antibacterial and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

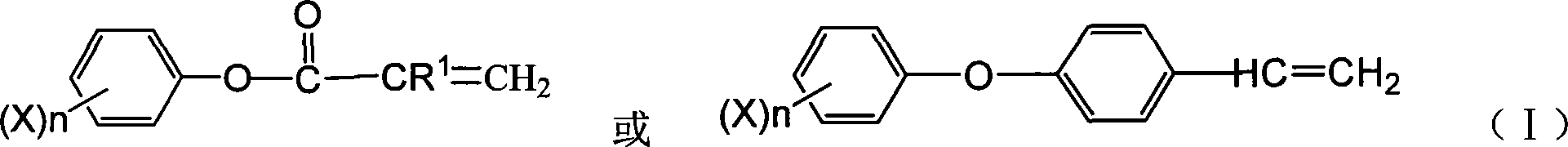

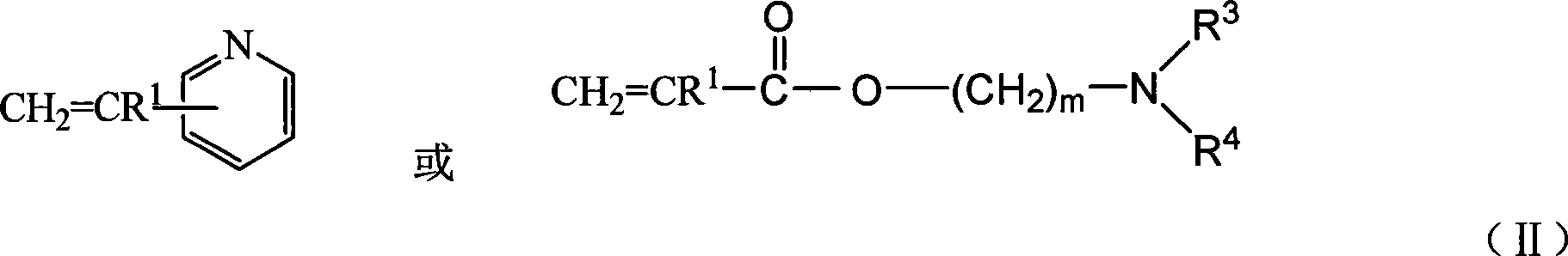

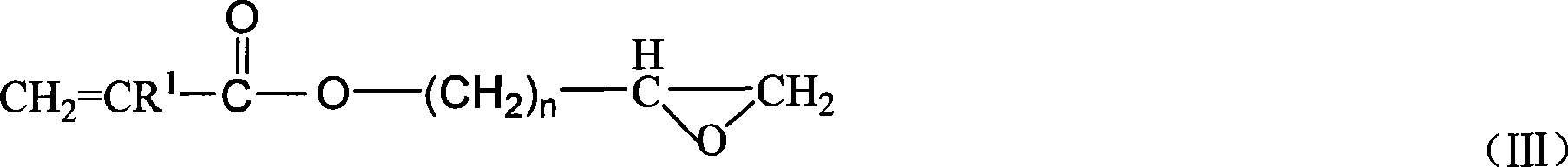

Method used

Image

Examples

example 1

[0041] Example 1: 4.33 grams (0.015mol) of dried sodium pentachlorophenate was placed in a 100ml round-bottomed flask, and 40 ml of ethyl acetate was added dropwise under magnetic stirring to completely dissolve sodium pentachlorophenate. At 0° C., a mixture of 20 ml of ethyl acetate and 1.3 ml of acryloyl chloride was added dropwise with a constant pressure dropping funnel (dropping completed within 0.5 h). After the addition was completed, the reaction was continued for 2h (0°C). After the reaction, the white insoluble matter was filtered off. The filtrate was washed several times with saturated brine until the aqueous layer was neutral. Pour the supernatant into a 100ml Erlenmeyer flask, add anhydrous Na 2 SO 4 Dry well. After 0.5h, it was filtered, and the supernatant was placed in a pear-shaped flask, and rotatively evaporated (45°C) for 0.5h. The product in the bottle was taken out and placed in a vacuum drying oven for 24 hours to be vacuum-dried for future use. Y...

example 2

[0042] Example two: Pentachlorophenyl acrylate (0.96 grams, 3mmol), 2-dimethylaminoethyl methacrylate (0.5ml, 3mmol), glycidyl methacrylate (0.2ml, 1.5mmol), AIBN (0.05g, 0.03mmol) was placed in a test tube, 3ml of THF was added, and dissolved with magnetic stirring at room temperature. Nitrogen gas (under the liquid surface) for 15 minutes, continue nitrogen gas (liquid surface) for 10 minutes, seal, and react in an oil bath (temperature 70°C for 6 hours). After the reaction finishes, cool the column (Al 2 o 3 ), and precipitated with petroleum ether to obtain a white viscous substance. Air dry followed by vacuum drying. Number average molecular weight: 50,000 g / mole Molecular weight distribution coefficient: 1.6, repeating unit ratio in the molecule: pentachlorophenyl acrylate: 2-dimethylaminoethyl methacrylate: glycidyl methacrylate = 0.9: 1: 0.1.

example 3

[0043] Example 3: Weighing CuBr 2 (0.09mmol) and AIBN (0.09mmol) were placed in a test tube, 2ml of THF was added, and dissolved with magnetic stirring at room temperature. After nitrogen gas (subsurface) for 10 min, 2-dimethylaminoethyl methacrylate (1.5 ml, 9 mmol) and glycidyl methacrylate (0.2 ml, 1.5 mmmol) were added. Continue to pass nitrogen for 5min, then add complexing agent PMDETA (25ul). Seal and react in an oil bath (T: 70°C for 6h). After the reaction finishes, add 2mlTHF in reaction system while hot, cross column after cooling (Al 2 o 3 ). Precipitate with petroleum ether to obtain a white viscous substance. After drying in air, it was dried in a vacuum oven (24h).

[0044] Put the weighed solid pentachlorophenyl acrylate (0.6 g, 0.19 mol) and CuBr (0.03 mmol) into a test tube, add 2 ml THF, and stir to dissolve. The prepared poly-2-dimethylaminoethyl methacrylate was dissolved in 2ml THF and added to the test tube, and nitrogen gas (under the liquid surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com