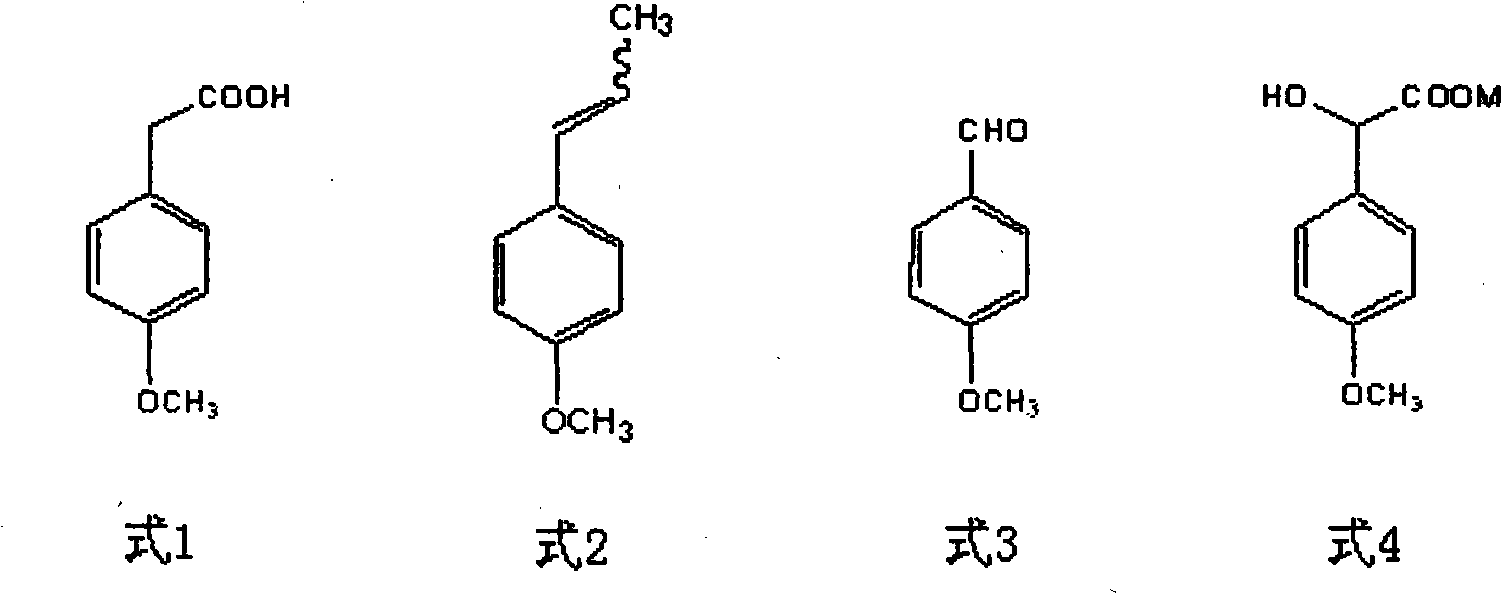

Method for preparing p-methoxypheny-lethyl acid from natural anethole

A technology of p-methoxybenzene and p-methoxybenzaldehyde, which is applied in the field of preparing p-methoxyphenylacetic acid from natural anethole, can solve the problems of harsh reaction conditions, difficult preparation and recovery, and low reaction yield. The effect of simplified operation, mild reaction conditions and simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 14.8g (0.1mol) of anethole, 8.88g of acetic acid, and 35.52g of cyclohexane in the reaction flask, stir evenly, control the reaction temperature at 20°C, and feed 2.7L (0.12mol) of O 3 , carry out ozonation reaction, 20min oxidation finishes. Add NaHSO with a concentration of 200g / L in the three-necked flask 3 Aqueous solution 57mL, then slowly add ozonide dropwise, react at 80°C for 60min, cool down to 50°C, adjust to pH ≥ 10 with sodium hydroxide solution, stand and separate layers, the upper layer is crude p-methoxybenzaldehyde, the lower layer is water The phase is extracted with cyclohexane and incorporated into the crude product of p-methoxybenzaldehyde. The crude product of p-methoxybenzaldehyde is dried with anhydrous sodium sulfate and rectified under reduced pressure. When the pressure is 667Pa and the temperature is 110-120°C, The distillate is a colorless or light yellow liquid which is p-methoxybenzaldehyde, weighing 10.88g, and the yield is 80.0%.

Embodiment 2

[0033] Add 14.8g (0.1mol) of anethole, 8.88g of acetic acid, and 35.52g of cyclohexane in the reaction flask, stir evenly, control the reaction temperature at 0°C, and feed 2.24L (0.10mol) of O 3 Carry out ozonation reaction, 40min oxidation finishes. Add NaHSO with a concentration of 200g / L in the three-necked flask 3Aqueous solution 52mL, then slowly add ozonide dropwise, react at 60°C for 90min, cool down to 50°C, adjust to pH ≥ 10 with sodium hydroxide solution, stand and separate layers, the upper layer is crude p-methoxybenzaldehyde, the lower layer is water The phase was extracted with cyclohexane and incorporated into the crude p-methoxybenzaldehyde; the crude p-methoxybenzaldehyde was dried with anhydrous sodium sulfate and rectified under reduced pressure. When the pressure was 667Pa and the temperature was 110-120°C, The distillate is a colorless or light yellow liquid which is p-methoxybenzaldehyde, weighing 9.79g and yielding 71.9%.

Embodiment 3

[0035] Add 14.8g (0.1mol) of anethole and 44.4g of ethanol in the reaction flask, stir well, control the reaction temperature at 0°C, adjust the ozone flow, and then feed 4.48L (0.20mol) of O 3 Carry out ozonation reaction, 40min oxidation finishes. Add concentration of 200g / L Na in the three-necked flask 2 SO 3 Aqueous solution 57mL, then slowly add ozonide dropwise, react at 60°C for 90min, cool down to 50°C, adjust to pH ≥ 10 with sodium hydroxide solution, stand and separate layers, the upper layer is crude p-methoxybenzaldehyde, the lower layer is water The phase is extracted with cyclohexane and incorporated into the crude product of p-methoxybenzaldehyde. The crude product of p-methoxybenzaldehyde is dried with anhydrous sodium sulfate and rectified under reduced pressure. When the pressure is 667Pa and the temperature is 110-120°C, The distillate was a colorless or pale yellow liquid, which was p-methoxybenzaldehyde, weighing 9.52 g, and the yield was 70.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com