Method for preparing complex particles of polymers with ultraviolet absorption radical and inorganic oxide by ultrasound irradiation

A technology of inorganic oxides and composite particles, which is applied in the field of preparation of polymer composite materials, can solve the problems of reduced purity, reduced anti-ultraviolet performance of composite particles, and poor particle dispersibility, etc., to achieve fast reaction speed and good anti-aging Ultraviolet light performance, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

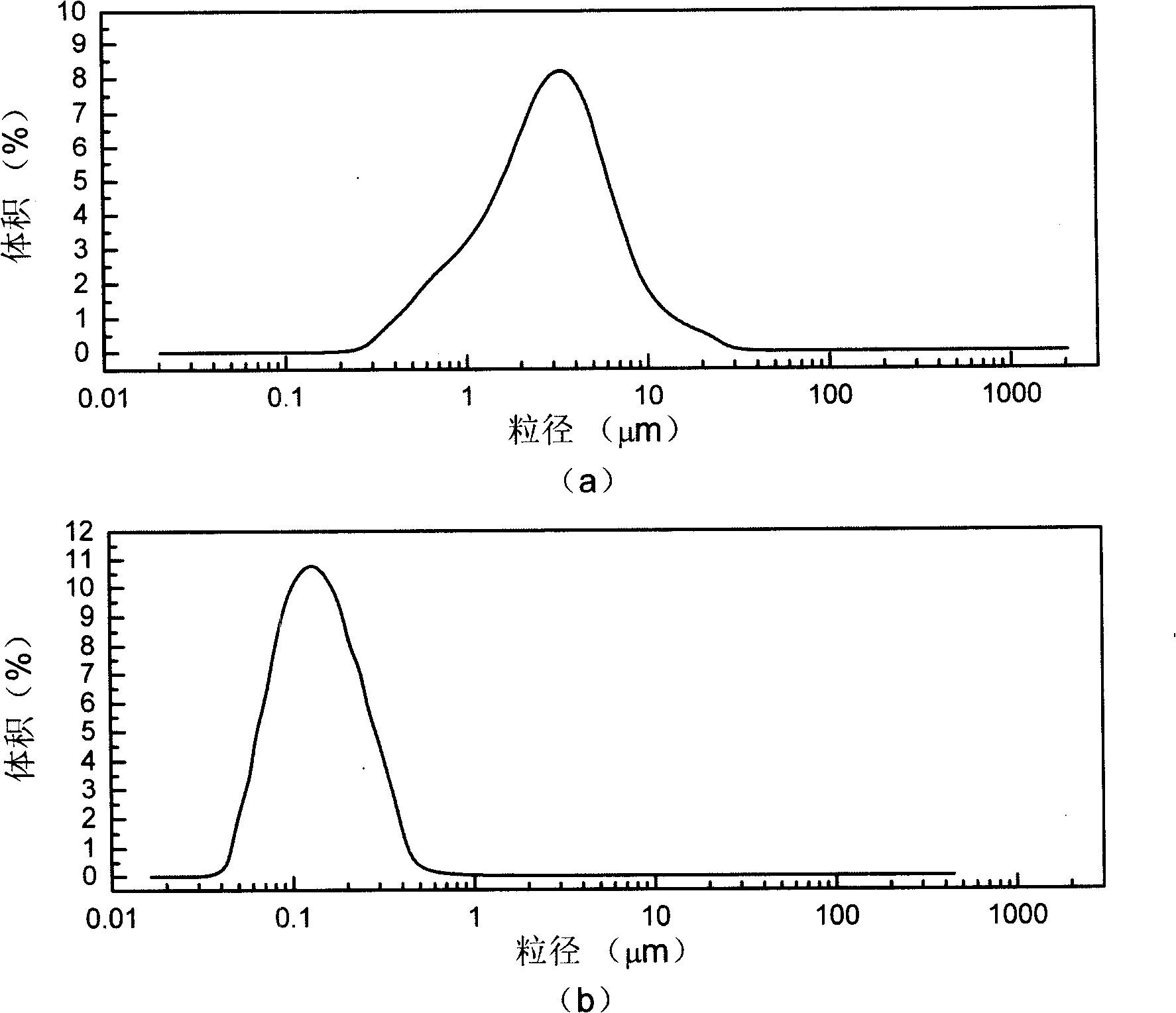

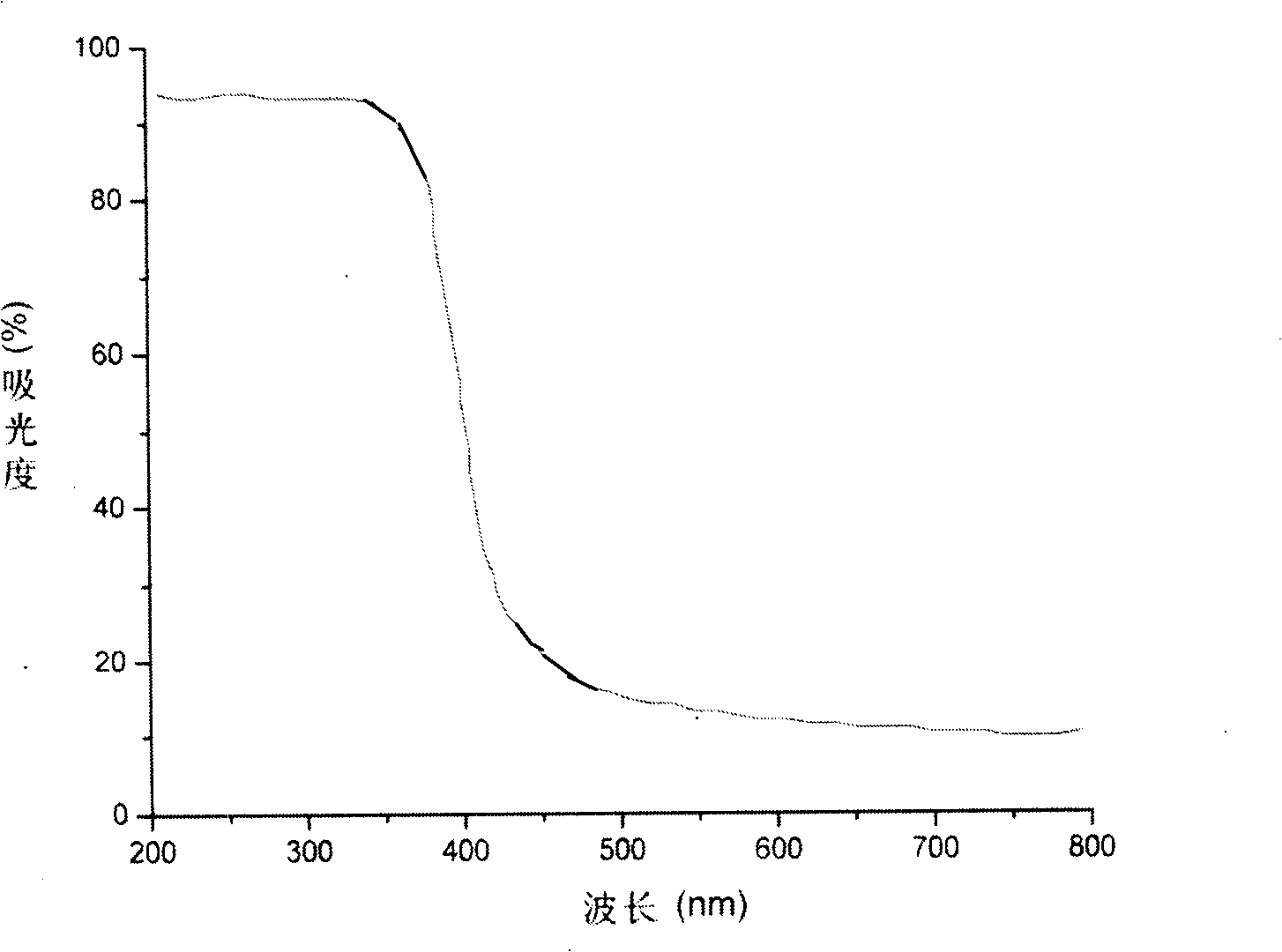

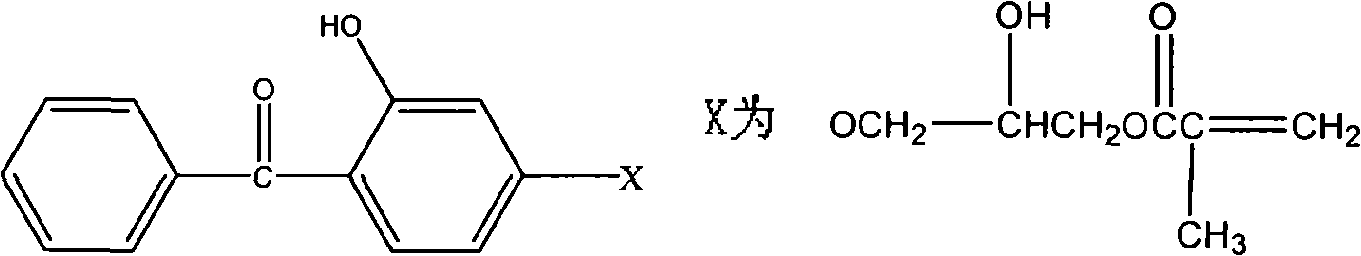

Embodiment 1

[0035] Weigh 1g of titanium dioxide, 0.05g of vinyltrimethoxysilane coupling agent, and 10g of ethanol, disperse the titanium dioxide particles in ethanol dissolved in coupling agent, add them to the ultrasonic irradiation reactor, and then insert the ultrasonic horn into the reaction In the container, the power is 250W ultrasonic dispersion for 10 minutes, and then the slurry is transferred to a three-necked bottle with a thermometer, agitator and reflux condenser, reacted at a temperature of 65°C for 8 hours, dried at a temperature of 75°C and then ground Modified titanium dioxide particles were obtained. Modified titanium dioxide particles 1g, deionized water 50g, methyl methacrylate 5g, polymeric emulsifier maleic anhydride derivative sodium sulfonate (M12) 0.5g, polymeric ultraviolet absorber 2-hydroxyl-4-(3 - 0.45 g of methacrylate-2-hydroxypropoxy) benzophenone (BPMA) was added to the ultrasonic irradiation reactor, and then the ultrasonic horn was inserted into the rea...

Embodiment 2

[0037]Weigh 4g of silicon dioxide, 0.75g of vinyltrimethoxysilane coupling agent, and 50g of ethanol, disperse the silicon dioxide particles in ethanol dissolved in coupling agent, add them to the ultrasonic irradiation reactor, and then transform the ultrasonic waves into The web rod was inserted into the reactor, and the power was 180W for ultrasonic dispersion for 8 minutes, then the slurry was transferred to a three-necked bottle with a thermometer, agitator and reflux condenser, and reacted at a temperature of 60°C for 6 hours, and at a temperature of 70°C Grinding after drying to obtain modified silicon dioxide particles. Modified silica particles 4g, deionized water 100g, butyl acrylate 28g, polymeric emulsifier maleic anhydride derivative sodium sulfonate 5g, polymeric UV absorber 2-hydroxy-4-allyloxydiphenyl Add 6.5 g of ketone into the ultrasonic irradiation reactor, and then insert the ultrasonic horn into the reactor. Nitrogen was fed for about 8 minutes, the rate...

Embodiment 3

[0039] Weigh 2g of silicon dioxide, 0.65g of vinyltriethoxysilane coupling agent, and 30g of ethanol, disperse the silicon dioxide particles in ethanol dissolved in coupling agent, add them to an ultrasonic irradiation reactor, and then The horn was inserted into the reactor, and the power was 300W for ultrasonic dispersion for 5 minutes, then the slurry was transferred to a three-necked bottle with a thermometer, a stirrer and a reflux condenser, and reacted at a temperature of 45°C for 7 hours, and at a temperature of 65°C After drying at ℃, the modified silicon dioxide particles are obtained by grinding. Mix 2g of modified silica particles, 80g of deionized water, 25g of methyl methacrylate, 2g of polymeric emulsifier maleic anhydride derivative sodium sulfonate, polymeric UV absorber 2-hydroxy-4-methacryloyl Add 3.5 g of oxybenzophenone into the ultrasonic irradiation reactor, and then insert the ultrasonic horn into the reactor. Nitrogen was fed for about 6 minutes at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com