Method for producing nano ecological matrix for water purification

A technology of water purification and production methods, applied in the field of textiles and nanometers, which can solve problems affecting the performance of nanomaterials, failure to achieve filtration, antibacterial and antibacterial surface properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

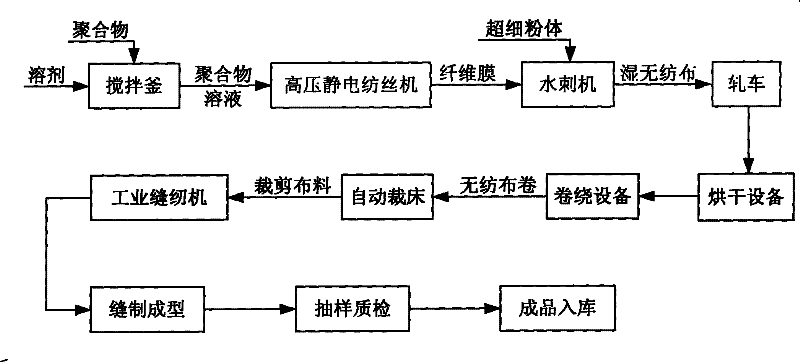

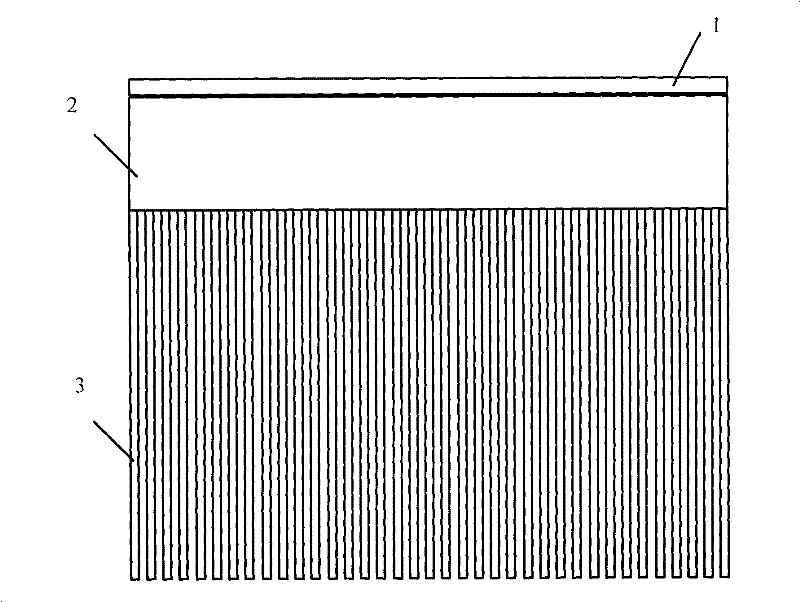

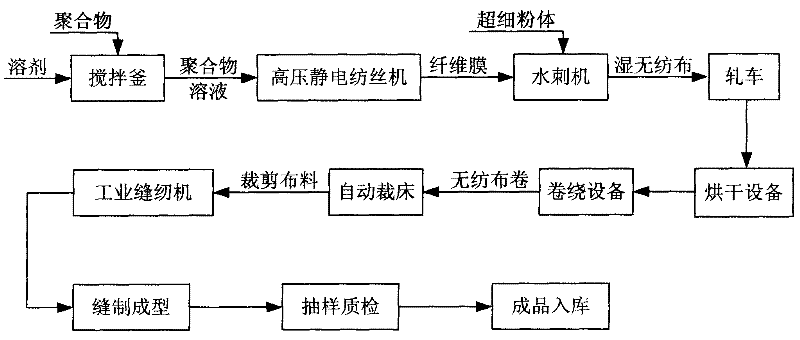

[0020] seefigure 1 , the present invention includes stirred tank, ethylene-vinyl alcohol copolymer EVOH (hydrophilic high molecular polymer), high-voltage electrospinning machine, tourmaline, hydroentangling machine, paddle car, hot air drying and hot air drying drum combined drying Drying equipment, winding equipment, automatic cutting machine, industrial sewing machine, chemical fiber high-strength industrial sewing thread. First of all, isopropanol and water are mixed in a volume ratio of 7:3 to form a solvent and added to a stirred tank with a heating jacket, then the ethylene-vinyl alcohol copolymer EVOH with better hydrophilicity is added, and at a heating temperature of 80 Dissolve EVOH completely at ℃ to form a spinning solution. Then, the spinning solution was injected into the capillary nozzle of the high-voltage electrospinning machine through a metering pump, and the diameter of the capillary was 500 μm. During the spinning process, the spinning voltage was set to...

Embodiment 2

[0024] In a section of river in Pudong, Shanghai, the nano-ecological base of the present invention was used to control black and odor. The river engineering section was 500m long, 8m wide, and 3m deep. During remediation, evenly put 600m in the river 2 The nano-ecological base, after 2 weeks, the mold hanging on the ecological base was good, and the water quality began to improve obviously, and the water quality has been improved to V-class water after 3 months. The water quality monitoring before and after the river regulation is shown in the table below.

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com