Positive light-sensitive polyamic ester resin composition and its preparation and use

A technology of polyamic acid ester and resin composition, which is applied in the direction of photomechanical equipment, photoplate making process coating equipment, optics, etc., can solve the problems of large amount of photosensitizer, poor process repeatability, low photosensitivity, etc., and achieve the goal of photosensitizer The effect of low dosage, excellent mechanics and high photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a kind of preparation method of soluble polyamic acid ester resin, the method comprises the following steps:

[0017] 1) reacting fluorine-containing aromatic diacid diester with thionyl chloride to form corresponding fluorine-containing aromatic diacid diester;

[0018] 2) dissolving the aromatic diamine and its mixture in an organic solvent to form a homogeneous solution;

[0019] 3) Adding the aromatic diamine and its mixture solution in batches to the fluorine-containing aromatic dichloride diester solution;

[0020] 4) Then add the molecular weight regulator, and the reaction mixture generates polyamic acid ester resin solution by polycondensation reaction at room temperature;

[0021] 5) Pour the resin solution into excess water to precipitate solid resin;

[0022] 6) Wash and dry the solid resin for use.

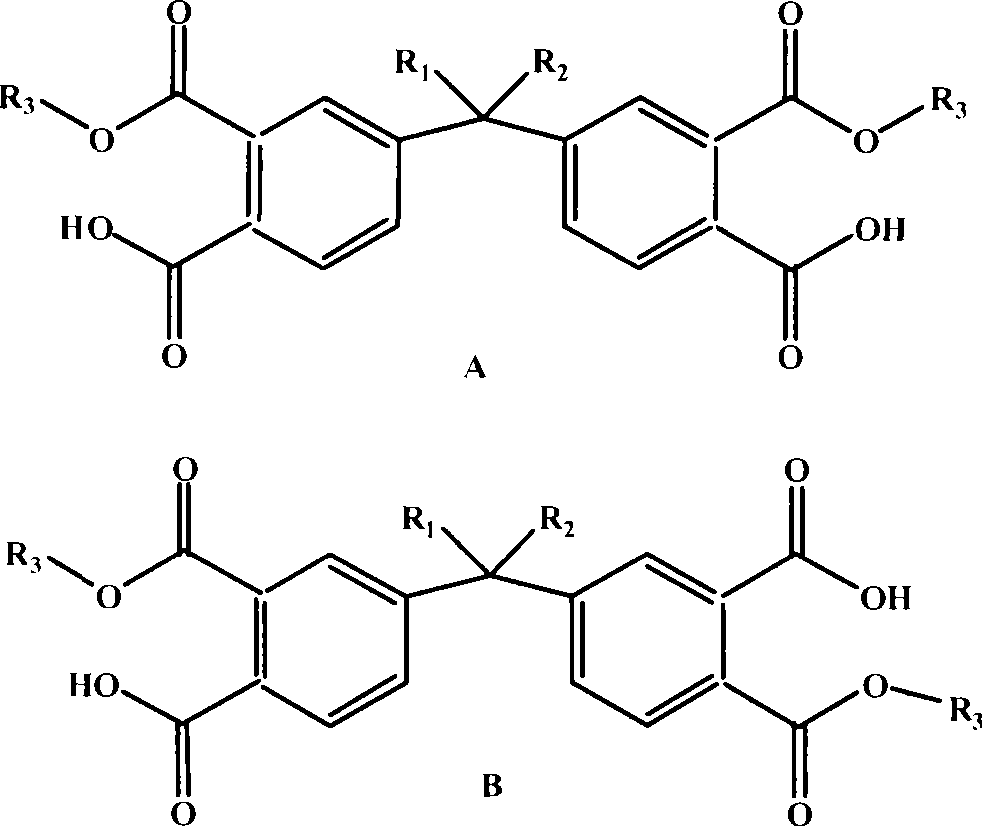

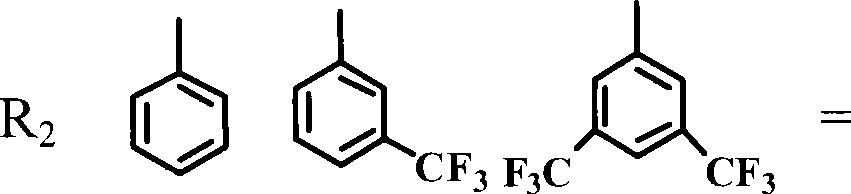

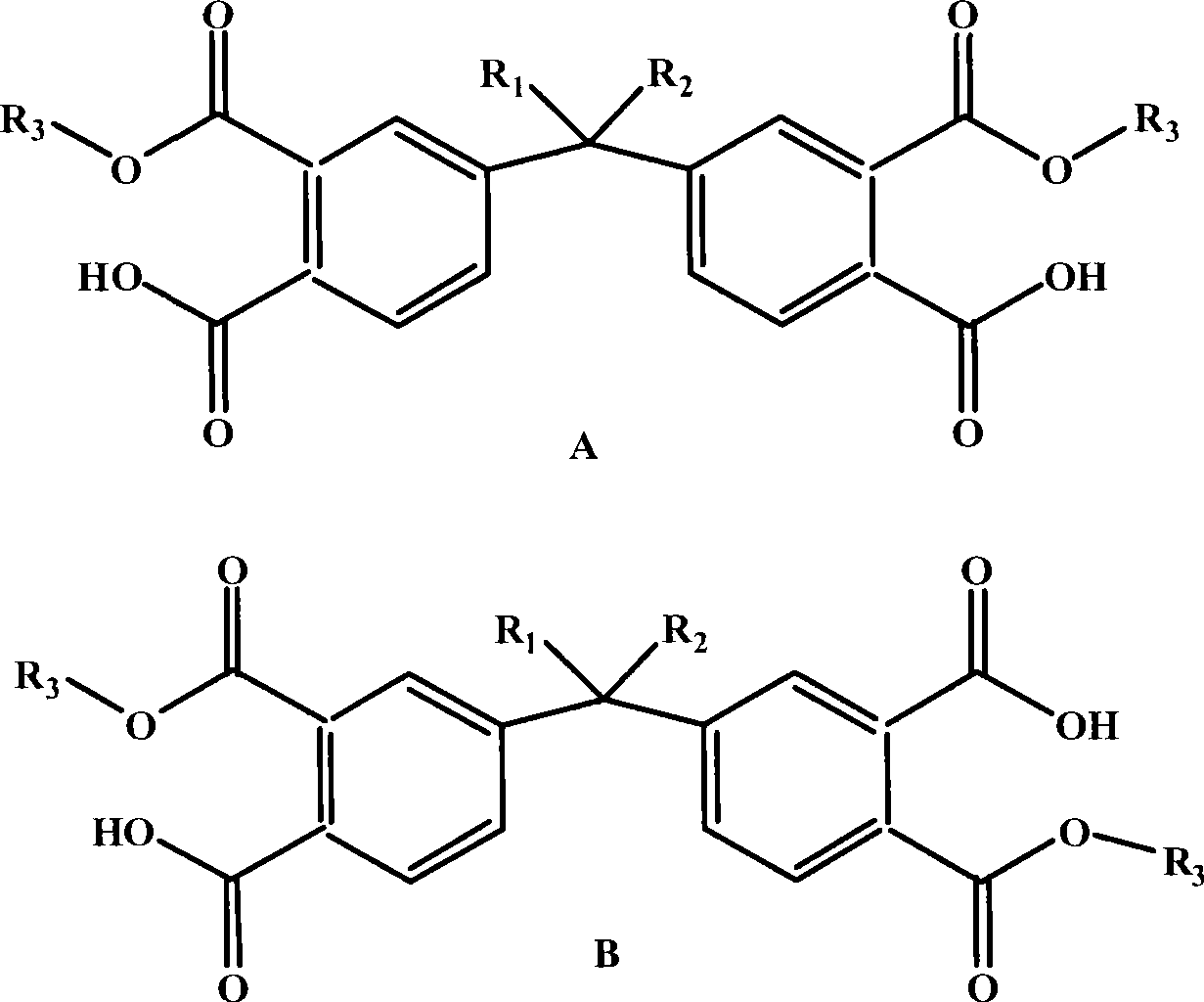

[0023] The positive photosensitive polyamic acid ester resin composition of the present invention is characterized in that the fluori...

Embodiment 1

[0034] In a 1500ml three-neck round bottom flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 260 parts by weight of 4,4'-[2,2,2-trifluoro-1-(3-trifluoromethylbenzene base) ethyl] diphthalic anhydride (TFDA), 130 parts by weight of butanol and 550 parts by weight of tetrahydrofuran. The reaction mixture was heated to 80°C and stirred for 6 hours to generate the corresponding dibutyl aromatic diacid. The above product is reacted with 98 parts by weight of thionyl chloride at 0-10° C. for 2 hours and at room temperature for 4 hours to generate the corresponding fluorine-containing aromatic diacid chloride dibutyl ester.

[0035] In a 1000ml three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 160 parts by weight of 2,2'-bis(3-amino-4-phenol) hexafluoropropane and 500 parts by weight of N, N-dimethylacetamide, start stirring to form a homogeneous solution; then, react ...

Embodiment 2

[0041] In a 1000ml three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer and a nitrogen protection device, add 210 parts by weight of 2,2'-bis(3-amino-4-phenol)propane and 500 parts by weight of N,N- Dimethylacetamide, start stirring, so that it forms a homogeneous solution; then, react 2 hours at 0~10 ℃ with the fluorine-containing aromatic diacid dibutyl chloride prepared in Example 1 and 5 parts by weight of 4-phenylynylphthalic anhydride , Polycondensation reaction occurred at room temperature for 10 hours, the reaction solution was poured into a large amount of deionized water, the solid was precipitated, filtered, and vacuum-dried to generate polyamic acid ester resin.

[0042] The above-mentioned polyamic acid ester resin of 40 parts by weight is added the N of 50 parts by weight, N'-dimethylacetamide, stirred at room temperature for 2 hours, and made it form a homogeneous solution.

[0043] 10 parts by weight of propylene oxide triethoxysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com