Teeth spherical heavy oil hydrotreating catalyst and preparation method thereof

A hydrotreating and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor hydrodenitrogenation activity, small specific surface area, The problem of high reaction temperature, to achieve the effect of good effect, high specific surface area and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] plan 1

[0032] (1) Preparation of toothed spherical alumina carrier precursor

[0033] 200g of commercial aluminum hydroxide produced by the nitric acid method, 60g of commercial aluminum hydroxide produced by the carbonization method, 10g of scallop powder, 10g of sodium polyacrylate and 13g of citric acid powder, after mixing and grinding for 30min with a mixer, add 80g of deionized water and 16g of 60% nitric acid was continued to be mixed and milled for 40 minutes with a mixer to obtain a soft block plastic body.

[0034] (2) Preparation of toothed spherical alumina carrier

[0035] The soft block-shaped plastic body prepared in step (1) is put into the trough of the extruder, extruded through the toothed spherical orifice plate, and then pelletized to obtain the shaped carrier. Then, it was cured at room temperature for 1 hour, dried at 100-110°C for 2 hours in an air atmosphere, and baked in a muffle furnace at 500-550°C for 4 hours to obtain a toothed spherical ...

Embodiment 2

[0053] This embodiment is an evaluation experiment of the reference product and the invention products 1-5, and the experiment is carried out on a 100ml small-scale hydrogenation device. According to the following steps 1) and 2), the parallel experiment of catalytic hydrogenation reaction is carried out to reference substance, invention product 1~5 respectively, and the steps are as follows:

[0054] 1) Load 100ml of catalyst in the reactor, heat up to 320° C., and then presulfurize the kerosene containing 2% dimethyl disulfide for 8 hours under hydrogen atmosphere to obtain raw material oil.

[0055] 2) Then carry out the catalytic hydrogenation reaction of raw material oil, reaction conditions: hydrogen partial pressure 6.0MPa, liquid hourly space velocity 0.5 hour -1 , the volume ratio of hydrogen to oil is 800, and the reaction temperature is 372°C.

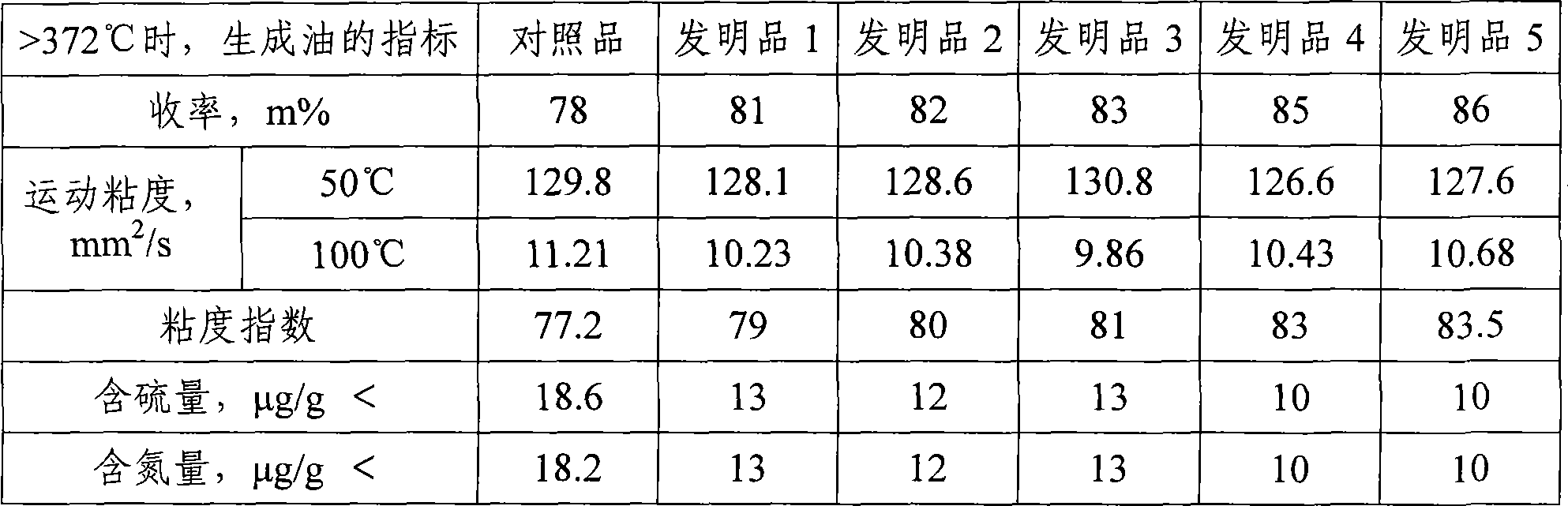

[0056] Table 2 Comparison of experimental results (various indicators of oil produced at >372°C)

[0057]

[0058] As...

Embodiment 3

[0063] (1) Preparation of toothed spherical alumina carrier precursor

[0064] 60g of commercial aluminum hydroxide produced by nitric acid method, 200g of commercial aluminum hydroxide produced by carbonization method, 8-10g of scallop powder, 10-12g of sodium polyacrylate and 10-13g of citric acid powder, mixed with a mixing mill for 10-30min Finally, add 80 g of deionized water and 16 g of 60% nitric acid, and continue to mix and grind for 100 to 120 min with a mixer to obtain a soft block plastic body.

[0065] (2) Preparation of toothed spherical alumina carrier

[0066] The soft block-shaped plastic body prepared in step (1) is put into the trough of the extruder, extruded through the toothed spherical orifice plate, and then pelletized to obtain the shaped carrier. Then, it was cured at room temperature for 1 hour, dried at 80-90°C for 4 hours in an air atmosphere, and baked at 550-600°C for 3 hours in a muffle furnace to obtain a toothed spherical alumina carrier.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com