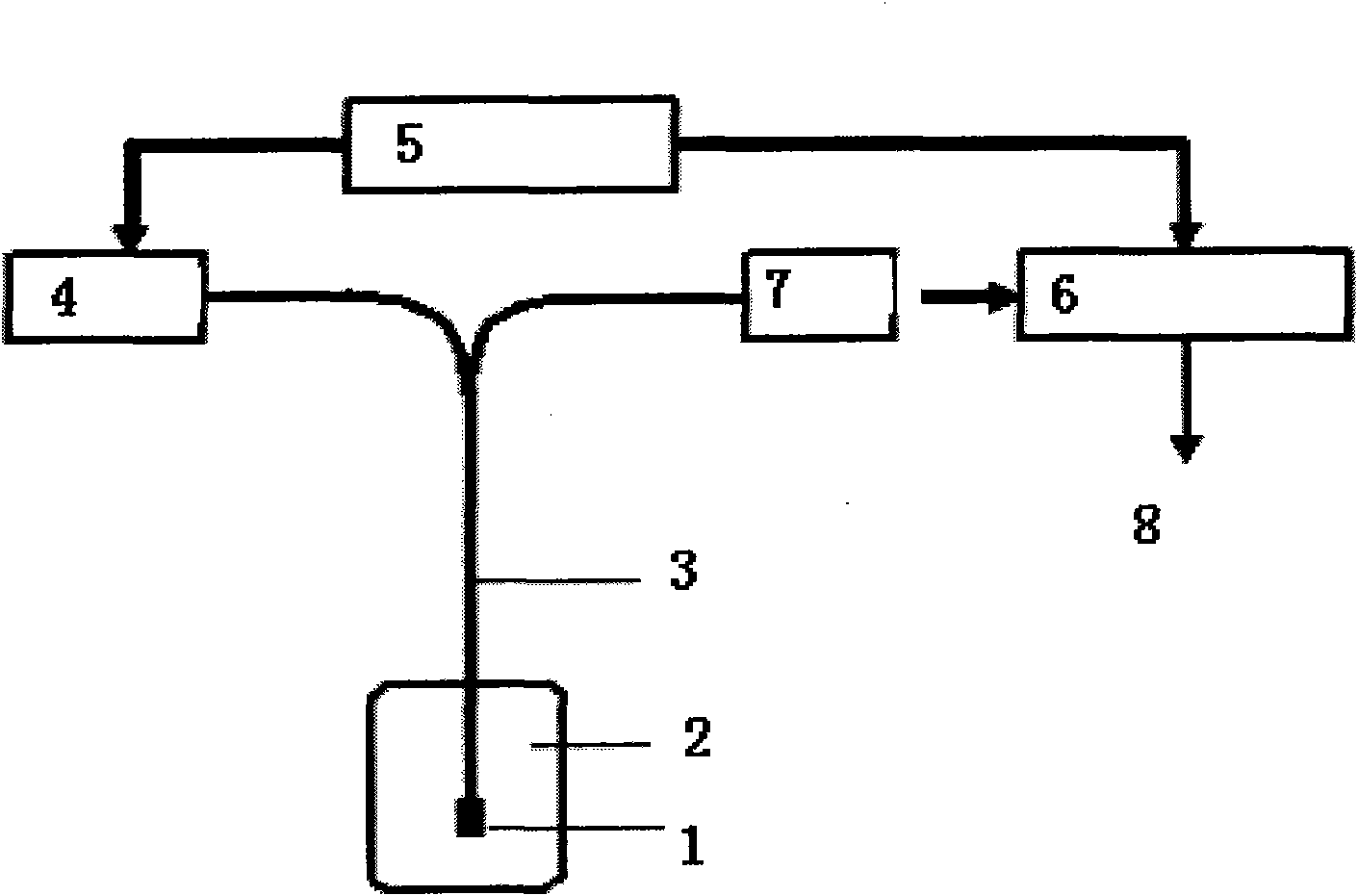

Thin-film material for optical fiber biosensor probe and preparation method thereof

A biosensor and thin-film material technology, applied in the field of optical fiber biosensor probe thin-film materials and their preparation, can solve the problems of reducing the sensitivity and accuracy of the sensor, disorderly arrangement, affecting the catalytic activity of enzymes, etc. Excellent biocompatibility, favorable effect for separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

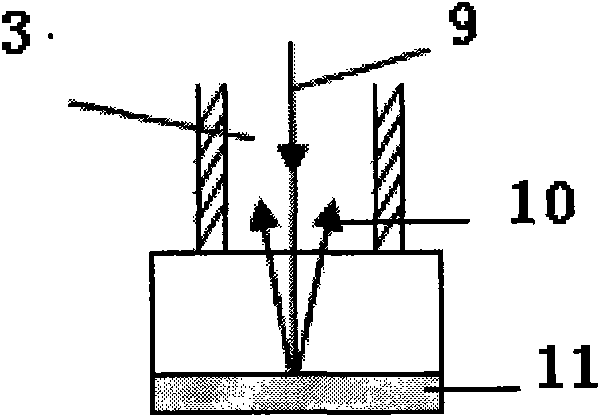

Method used

Image

Examples

Embodiment 1

[0029] Mix tetraethyl orthosilicate, 0.05mol / L hydrochloric acid, and formamide at a volume ratio of 8:4:1, and then add Ru(bpy) with a concentration of 8mg / ml to 1.75ml of the mixture 3 Cl 2 Fluorescent indicator 140 μl, sealed and stirred at room temperature until uniformly mixed, left still to obtain a sol solution, aged in an incomplete seal at room temperature for 2 days to obtain a sol-gel solution. Take 5ml of Fe immobilized with glucose oxidase (GOD) 3 o 4 @SiO 2 Nanocomposite magnetic particles (the concentration of the nanocomposite magnetic particles is 10 mg / ml) are dissolved in pH7.0 phosphate buffer solution, and then fully mixed with the aged sol-gel solution at a volume ratio of 1:1, and 0.1 ml of mixed sol solution was added dropwise on the surface of the treated glass substrate (the glass substrate was washed with hot concentrated sulfuric acid, absolute ethanol, and distilled water in sequence and dried), and it could be cured into a condensate of about 5...

Embodiment 2

[0032] Under mechanical stirring, in a 250mL three-necked flask, add Fe at a concentration of 10mg / ml 3 o 4 @SiO 2 Nanocomposite magnetic particle solution 3ml, 80 μ l APS (aminopropyltriethoxysilane), at room temperature, continue to mechanically stir for 12h, the reaction solution is separated by a combination of permanent magnet and centrifugation, and the composite particles are separated with absolute ethanol and secondary Wash with distilled water, and then disperse with double distilled water after sonication to obtain aminated Fe 3 o 4 @SiO 2 Nanocomposite magnetic particles. Take 5ml concentration of 10mg / ml aminated Fe 3 o 4 @SiO 2 Nanocomposite magnetic particles were activated by adding 4ml of glutaraldehyde aqueous solution with a concentration of 3% by volume, mechanically stirring for 2 hours at room temperature, and then washed three times with a phosphate buffer solution with a concentration of 0.01mol / L and pH=7.0. Add the activated carrier to (GOD) p...

Embodiment 3

[0036] Prepared Fe 3 o 4 Disperse with tetramethylammonium hydroxide to obtain Fe 3 o 4 ferrofluid. Mix cyclohexane, n-hexanol and surfactant Triton X-100 evenly at a mass ratio of 9:1:2, add 1.5ml of secondary distilled water to 60ml of the mixture as the dispersed phase, and stir for 5min to obtain a transparent and stable Water-in-oil microemulsion. In the microemulsion, add 2ml of magnetic fluid (10mg / ml), stir for 1h, add 1ml of ammonia water, and then add tetraethyl orthosilicate and amination reagent (TEOS and EPTES) with a volume ratio of 3:1, the total volume is 500μl , after continuous stirring for 24 hours, the surface aminated SiO 2 Magnetic nanocomposite particles. Silicon-shell magnetic nanocomposite particles react with glutaraldehyde to generate a C=N bond. In this way, an aldehyde group is introduced on the surface of the nanocomposite particle, and the aldehyde group can react with the amino group in the glucose oxidase molecule to make the enzyme mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com