Method for preparing gold nanocrystals with high density at room temperature and applications thereof

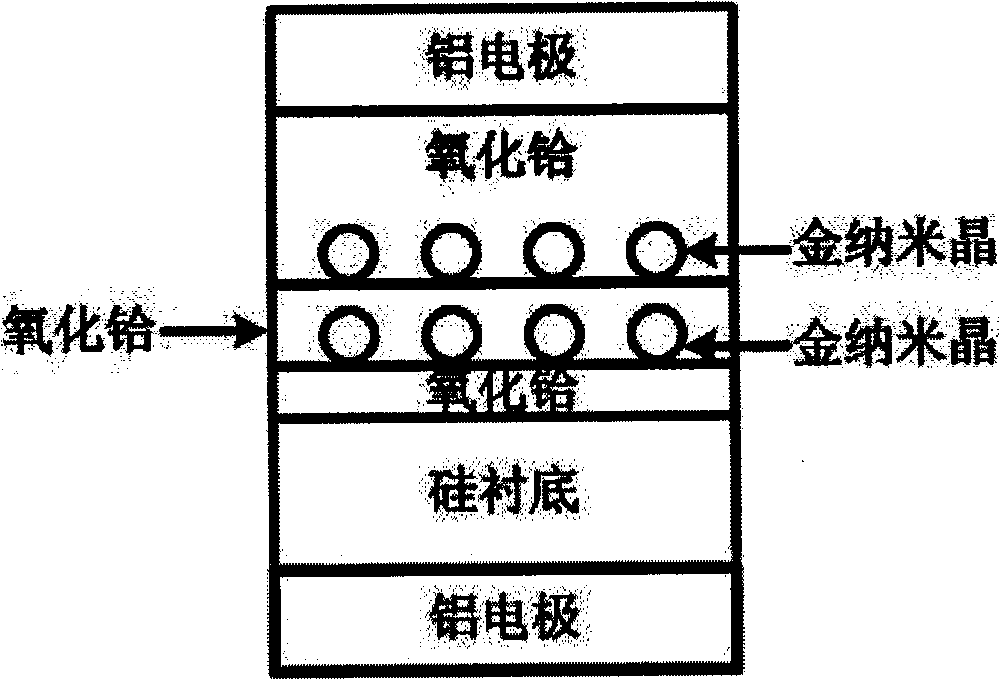

A gold nano, high-density technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of increasing device thermal stress, increasing memory energy consumption and cost, and unfavorable processing of nanodevices, so as to avoid thermal stress Produces, maintains stable, fully isolated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

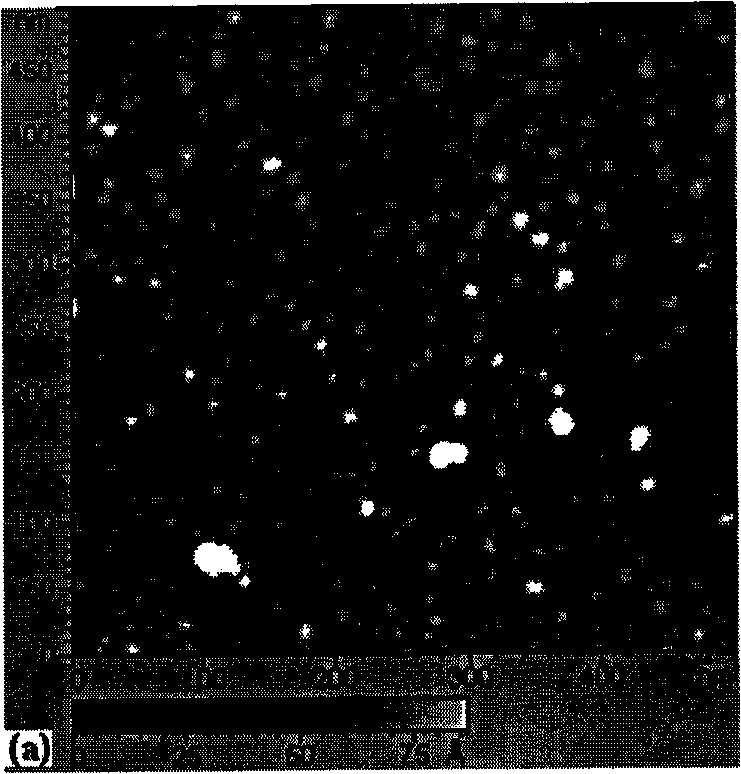

[0036] A method for preparing high-density gold nanocrystals at room temperature, comprising the steps of:

[0037] A, the preparation of gold sol:

[0038] The first step: add 1 milliliter of chloroauric acid water with a mass volume concentration of 1 to 3% into a flask filled with 100 milliliters of ultrapure water, and stir vigorously for 1 to 2 minutes;

[0039] The second step: add 1 ml of sodium citrate aqueous solution with a mass volume concentration of 1 to 3% dropwise in the mixed solution of the first step within 1 minute, and mix for 1 to 2 minutes;

[0040] Step 3: Add 1 milliliter of sodium borohydride solution (dissolved in a 1% sodium citrate aqueous solution) with a mass volume concentration of 0.065 to 0.085% in the above mixed solution, and continue stirring until the solution becomes Wine red color, gold sol configuration is completed, and the system temperature is maintained at room temperature throughout the preparation process.

[0041] B. Preparation...

Embodiment 2

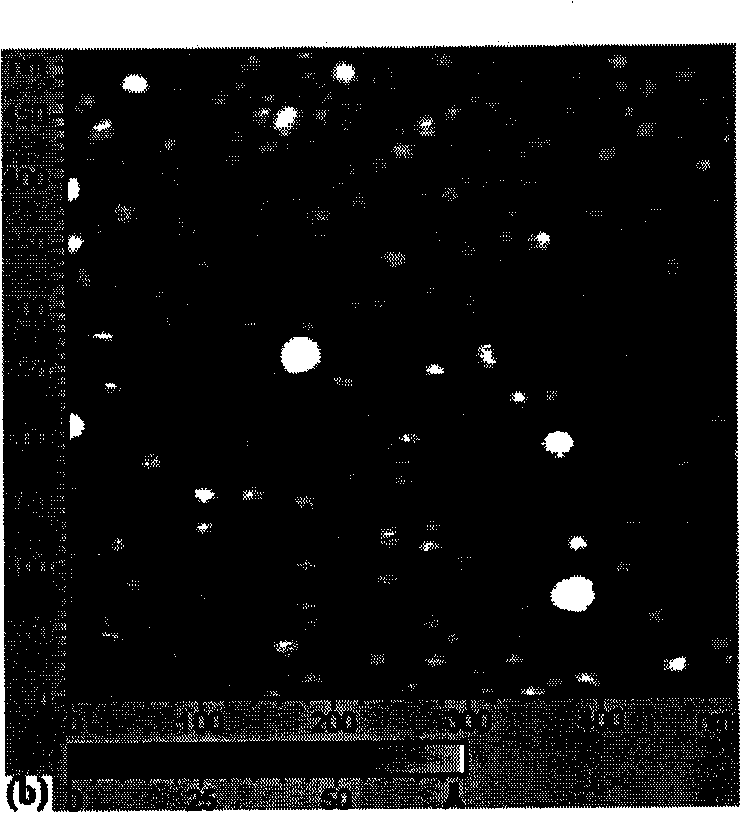

[0052] A method for preparing high-density gold nanocrystals at room temperature, comprising the steps of:

[0053] A, the preparation of gold sol: with embodiment 1

[0054] B. Preparation of high-density gold nanocrystals:

[0055] Step 1: In the atomic layer deposition reaction chamber, after standard cleaning of the p-type silicon wafer, atomic layer deposition of HfO with a thickness of 5 to 7 nanometers on the surface of the p-type silicon wafer 2 thin films, in which atomic layer deposited HfO 2 The reaction precursor of the film is tetrakis-(ethylmethylamino) hafnium (TEMAH) and water, and the deposition temperature is controlled at 280-320°C;

[0056] Step 2: Cover with HfO 2 The p-type silicon chip of the film is soaked in an aqueous solution of 5% aminopropyltrimethoxysilane (APTMS) in mass concentration, taken out after two hours, rinsed with a large amount of ultrapure water, and treated with ultrasound several times;

[0057] Step 3: Put the p-type silicon ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com