Preparation of fibrin magnetic micrometer material for separating mRNA and application thereof

A cellulose and magnetic technology, applied in magnetic materials, DNA preparation, magnetic objects, etc., can solve the problems of easy leakage of antibodies, strong non-specificity, and reduced separation effect of target objects, so as to ensure biological activity, simplify activation steps, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

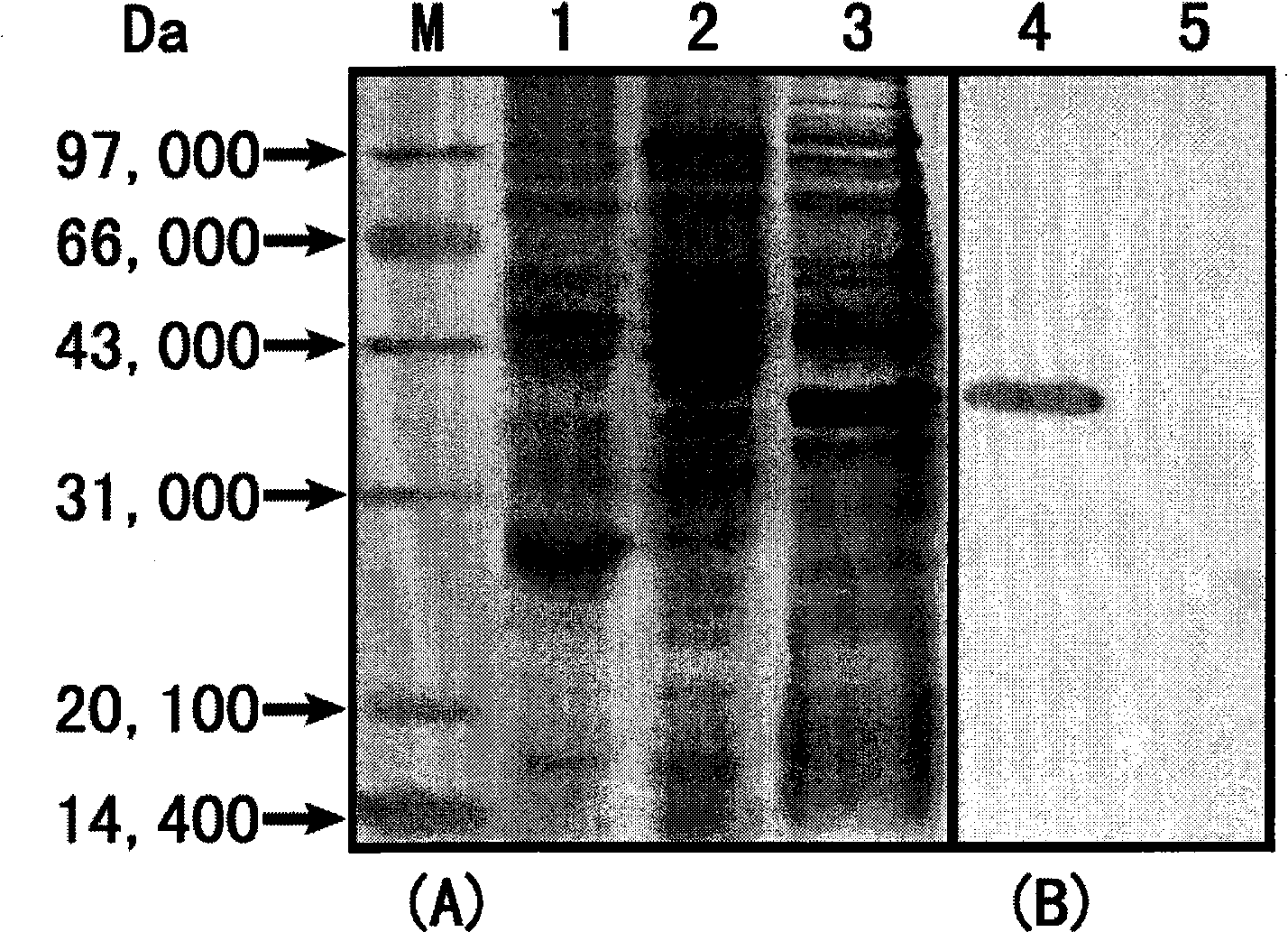

[0031] Example 1, Preparation of CBD-SA bifunctional fusion protein

[0032] 1. Extraction of Genomic DNA from Streptomyces lilacinus ZG0429

[0033] Treat Streptomyces lilacinus ZG0429 suspended in 100 μL lysate (50mmol / LTris, pH8, 25mmol / LEDTA, 3% SDS (m / v), 1.2% PVP (m / v)) in a 600W microwave oven by microwave method , time 2min, add 400μL 65℃ preheated extract solution (10mmol / L Tris, pH8, 1mmol / LEDTA, 0.3mol / LNaAc, 1.2%PVP(m / v)), incubate at 65℃ for 20min, then add etc. Volume of phenol: chloroform: isoamyl alcohol (25:24:1) and chloroform: isoamyl alcohol (24:1) for extraction to remove protein, and finally add 2 times the volume of -20 ° C pre-cooled absolute ethanol, in After standing at -20°C for 1 hour, the DNA was collected by centrifugation at 12,000 rpm, dissolved in 50 μL of sterilized water and stored at -20°C for later use.

[0034] 2. PCR amplification of streptavidin (SA) gene

[0035] According to the SA gene sequence (sequence number X03591) of Streptomy...

Embodiment 2

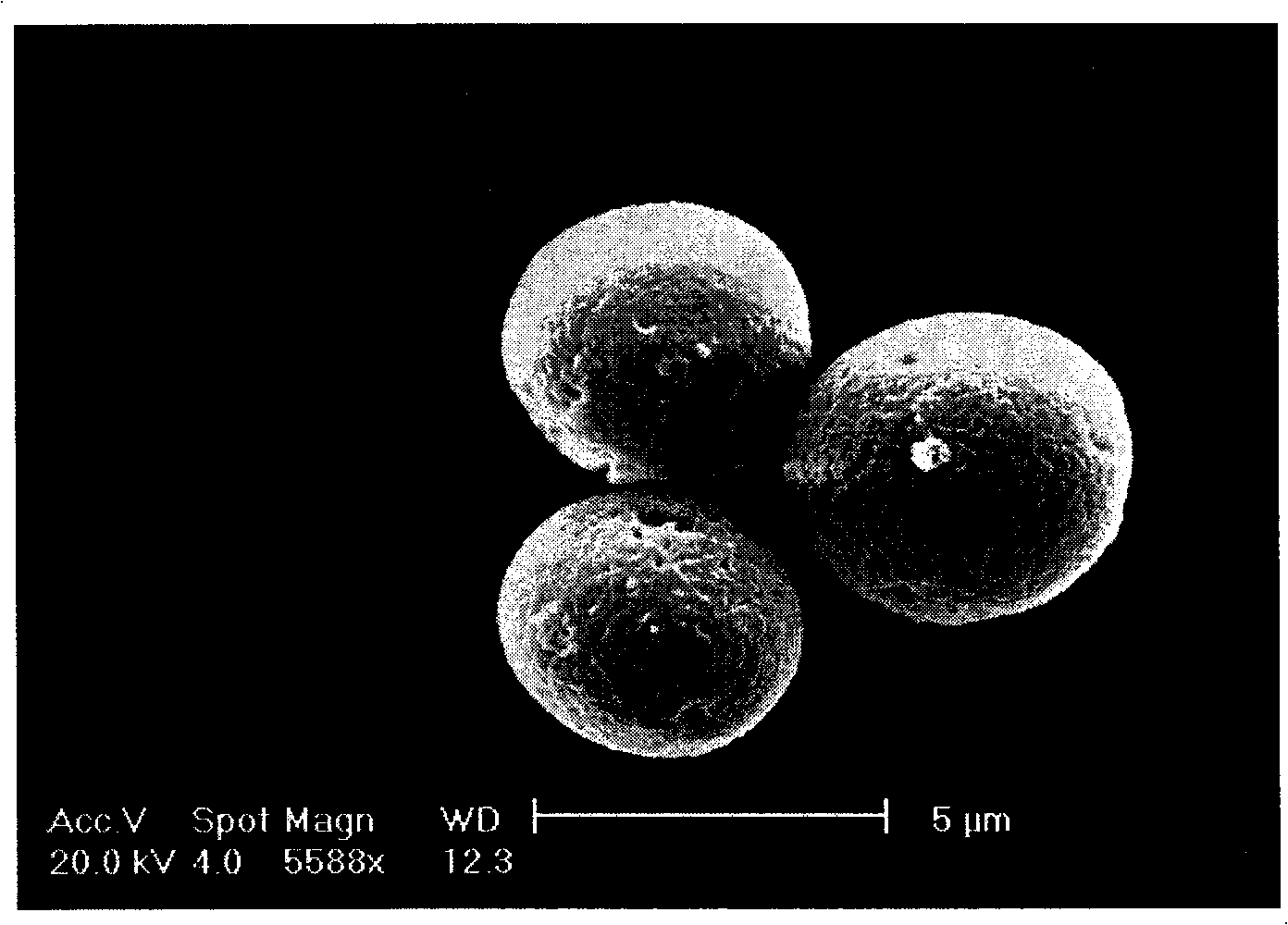

[0044] Embodiment 2, the preparation of cellulose magnetic micron material

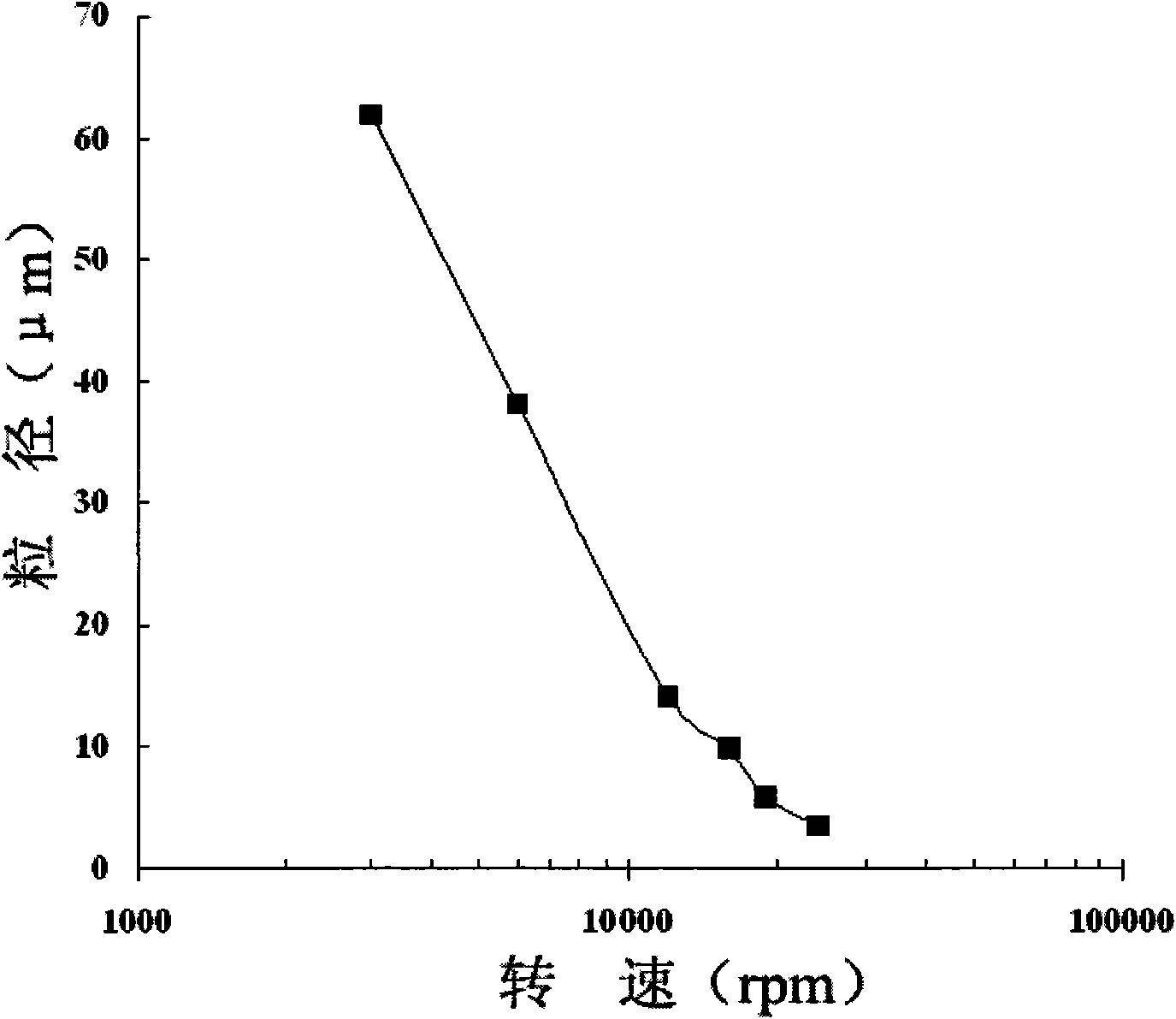

[0045] Take 2g of magnetic fluid and add it to 20mL of cellulose yellow gum solution. After fully stirring, use a homogenizer to homogenize for 2min under the conditions of 24000, 19000, 16000, 12000, 6000 and 3000rpm, and then add 100mL of organic phase (chlorobenzene and Carbon tetrachloride was mixed according to the volume ratio of 9:2, containing 2% Span-80 (v / v)), and fully homogenized at the same rotation speed for 2 minutes. Then transferred to 400mL organic phase, mechanically stirred at 400rpm. Heat in a 50°C hot water bath, and raise the temperature to 80°C, and keep it warm for 2.5 hours. Discard the organic phase, rinse with absolute ethanol 8 times, then alternately rinse with absolute ethanol and water, and finally fully rinse with water to obtain average particle sizes of MS1: 3.46, MS2: 5.82, MS3: 9.93, MS4 : 14.03, MS5: 38.04 and MS6: 61.86μm cellulose magnetic micro-materials, whe...

Embodiment 3

[0046] Example 3, Protein coupling efficiency of cellulose magnetic micron materials with different particle sizes

[0047] Take 100 μL each of the cellulose magnetic micro-materials with six particle sizes prepared in Example 2, add them to the fermentation lysate containing CBD-EGFP, and shake at room temperature. Measure the fluorescence emission intensity of the original fermentation lysate with a fluorescence detector at 30min, measure the fluorescence emission intensity of the fermented lysate after the adsorption of the above-mentioned cellulose magnetic micron material at the same time for 30min, calculate the fluorescence emission intensity consumed by the cellulose magnetic material, i.e. even connection efficiency. like Figure 4 As shown, the particle size of the cellulose magnetic material with the highest coupling efficiency is 5.82 μm, and it is determined that the optimum homogenate preparation speed is 19000 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com