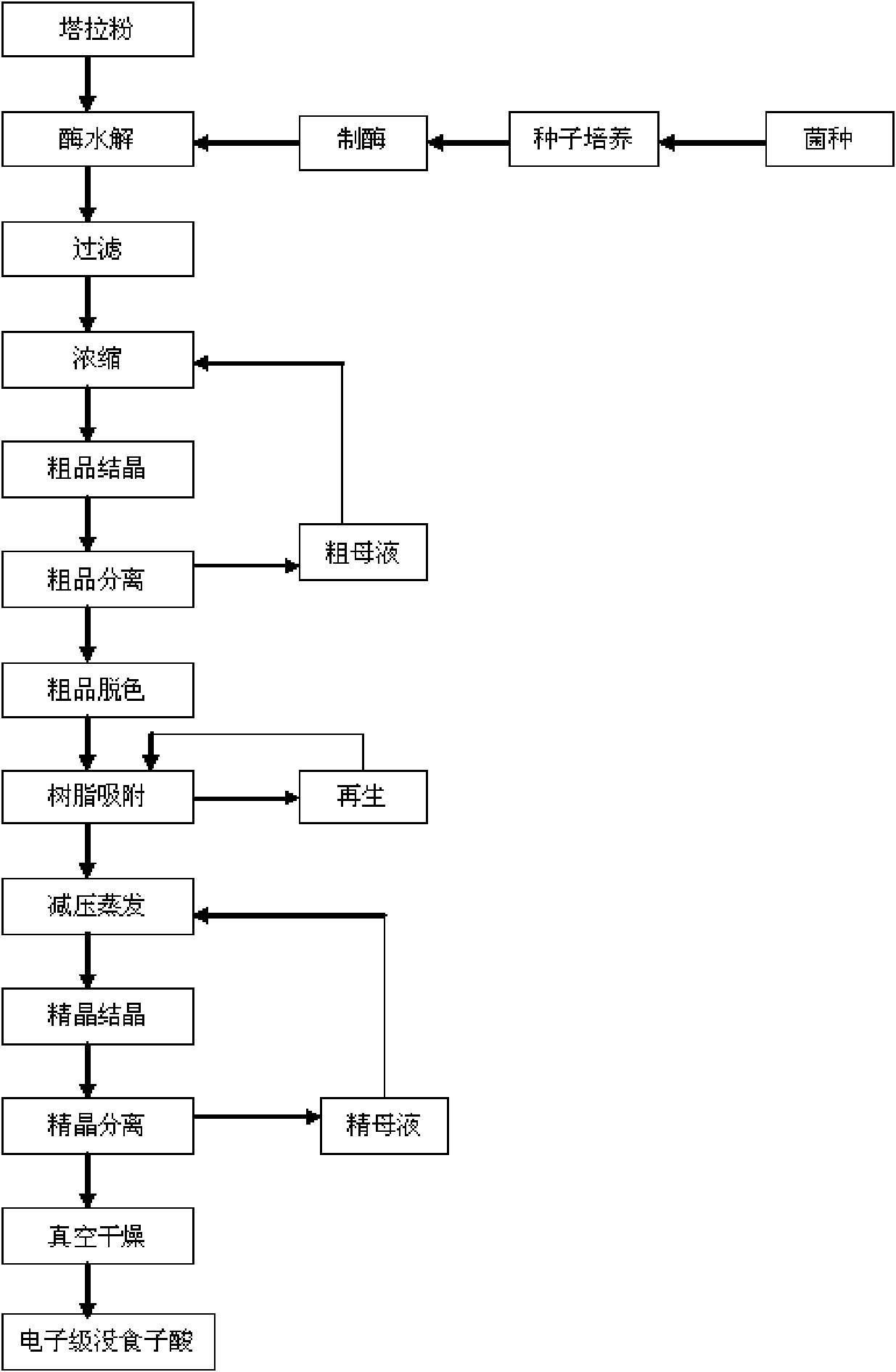

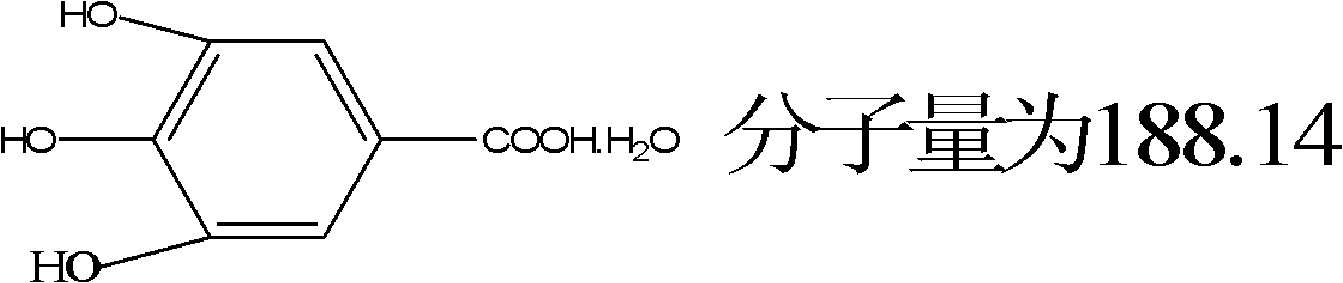

Method for preparing electronic grade gallic acid

A gallic acid and electronic-grade technology, which is applied in the field of producing electronic-grade gallic acid, can solve the problems of incomplete hydrolysis, long production cycle, and shortened resin service life, so as to increase product yield, reduce raw material unit consumption, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

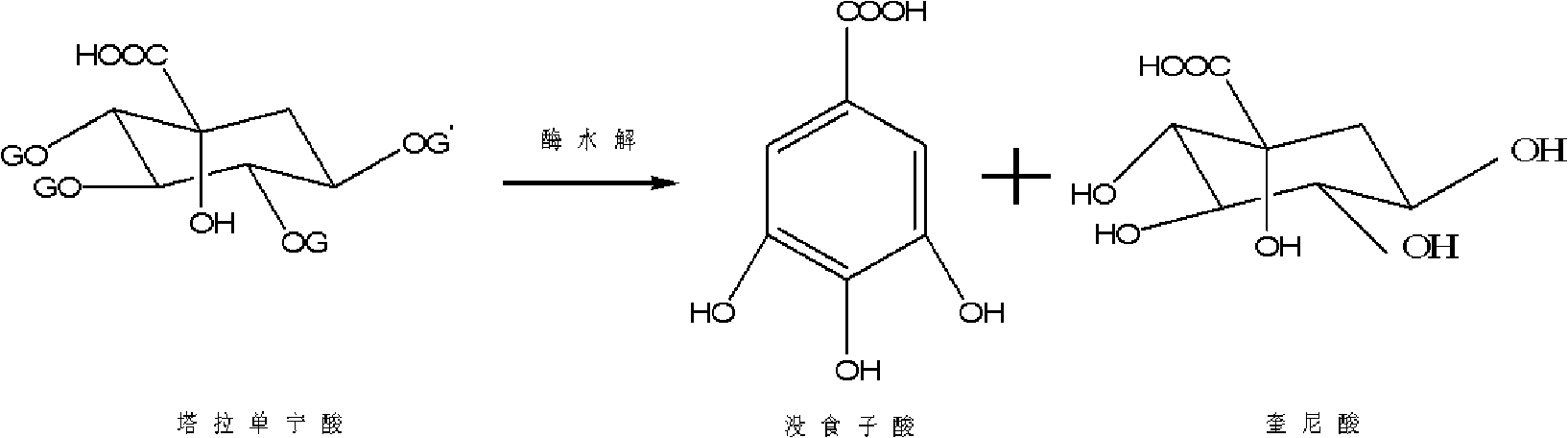

Method used

Image

Examples

Embodiment 1

[0030] (1) The seed cultivation of Aspergillus niger (Aspergillus niger) of No.3.3150 of China General Microorganism Culture Collection and Management Center

[0031] Aspergillus niger seed medium is (unit: W / V): 0.5% tannic acid, 1.2% glucose, 0.1% peptone, 0.05% citric acid, 1% NH 4 CL, 0.3%KH 2 PO 4 , 0.3% Na 2 HPO 4 .12H 2 O, 0.05% MgSO 4 .7H 2 O, agar 3%; cultured at 30°C, 140r / min for 38 hours.

[0032] (2) Aspergillus niger fermentation enzyme production

[0033] Aspergillus niger fermentation enzyme medium is (unit: W / V): 1.0% glucose, 0.5% sucrose, 0.1% peptone, 0.05% citric acid, 0.4% soluble starch, 1% NH 4 CL, 0.3%KH 2 PO 4 , 0.3% Na 2 HPO 4 .12H 2 O, 0.1% KCl, 0.03% CaCl 2 , 0.05% MgSO 4 .7H 2 O, 8% tannic acid; transfer to the fermentation medium of tannic acid with 6% (W / V) inoculation amount, 26~30 ℃, cultivate 70~75 hours under the condition of 130~140r / min, filter to obtain Enzyme solution.

[0034] (3) Enzymatic hydrolysis

[0035] Put 15K...

Embodiment 2

[0045] (1) The seed cultivation of Aspergillus niger (Aspergillus niger) of No.3.3150 of China General Microorganism Culture Collection and Management Center

[0046] Aspergillus niger seed medium is (unit: W / V): 0.5% tannic acid, 1.2% glucose, 0.1% peptone, 0.05% citric acid, 1% NH 4 CL, 0.3%KH 2 PO 4 , 0.3% Na 2 HPO 4 .12H 2 O, 0.05% MgSO 4 .7H 2 O, agar 3%; cultured at 30°C, 140r / min for 38 hours.

[0047] (2) Aspergillus niger fermentation enzyme production

[0048] Aspergillus niger fermentation enzyme medium is (unit: W / V): 1.0% glucose, 0.5% sucrose, 0.1% peptone, 0.05% citric acid, 0.4% soluble starch, 1% NH 4 CL, 0.3%KH 2 PO 4 , 0.3% Na 2 HPO 4 .12H 2 O, 0.1% KCl, 0.03% CaCl 2 , 0.05% MgSO 4 .7H 2 O, 6% tannic acid; transfer to tannic acid fermentation medium with 5% inoculum amount, cultivate for 70-75 hours at 26-30° C., 130-140 r / min, and filter to obtain enzyme liquid.

[0049] (3) Enzymatic hydrolysis

[0050] Put 20Kg of Tara powder with 48% ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com