Method for preparing cerous phosphate nano wire

A technology of nanowires and cerium phosphate, applied in the field of nanomaterials, can solve the problems of water pollution, high requirements on reaction equipment, easy volatilization to the air, etc., and achieves the effects of reducing production costs, being environmentally friendly, and facilitating industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the cerium phosphate nanowire provided by the invention comprises the following steps:

[0024] Step 1: Prepare Ce separately 3+ Saline solution and PO 4 3- saline solution.

[0025] The Ce 3+ Saline solution and PO 4 3- The salt solution was respectively prepared with soluble Ce commonly used in this field 3+ Salt and soluble orthophosphoric acid (PO 4 3- ) salt as the solute and water as the solvent. For example, the soluble Ce 3+ The salt can be cerium nitrate, cerium chloride or cerium sulfate, the soluble orthophosphate PO 4 3- The salt can be sodium phosphate, ammonium phosphate or potassium phosphate, etc., such as diammonium phosphate, disodium hydrogen phosphate, ammonium dihydrogen phosphate, sodium dihydrogen phosphate, sodium phosphate, dipotassium hydrogen phosphate or potassium dihydrogen phosphate. In particular, orthophosphoric acid can also be used directly. In order to improve product precision, commercially avail...

Embodiment 2

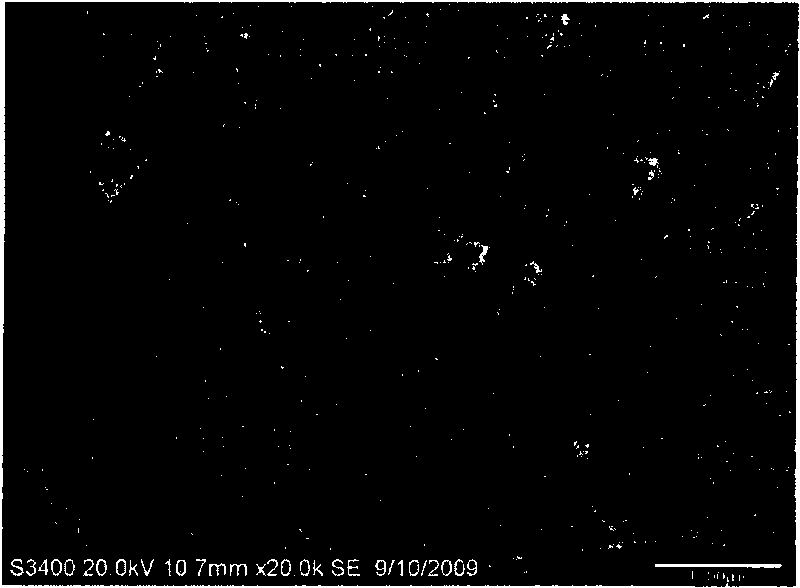

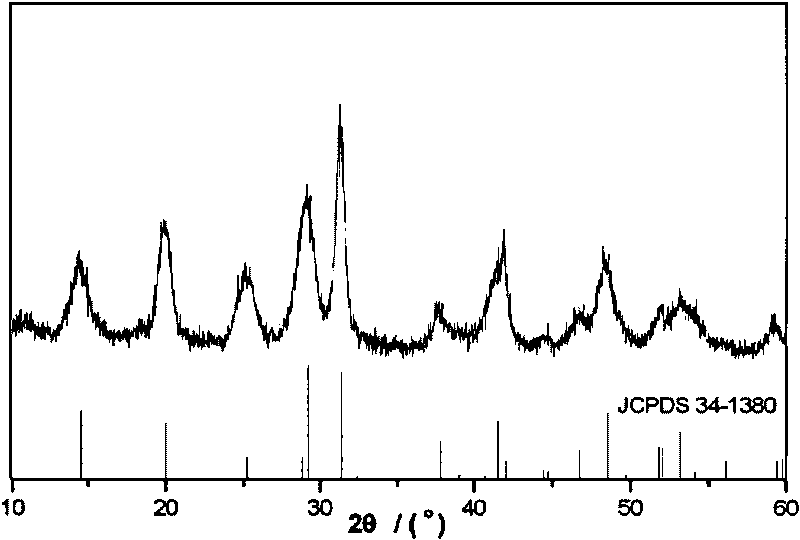

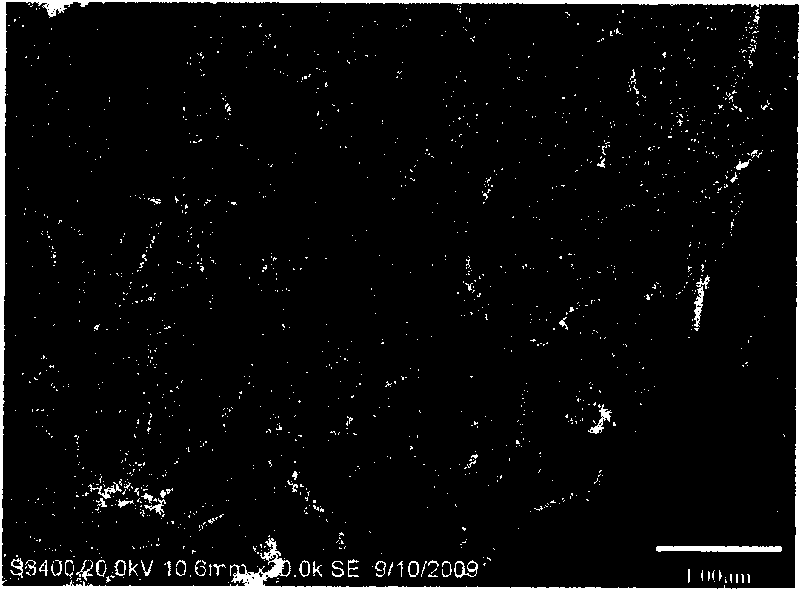

[0039] Weigh a certain mass of cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O] and disodium phosphate [Na 2 HPO 4 12H 2 [0], be prepared with deionized water to be respectively 25 milliliters of cerium nitrate aqueous solution and disodium hydrogen phosphate aqueous solution that concentration is 0.1 mol / liter. Place the cerium nitrate solution in a beaker or Erlenmeyer flask, stir with a magnetic stirrer at a speed of 150 rpm, and drop the disodium hydrogen phosphate solution into the cerium nitrate solution while stirring. Stirring was continued for 0.5 hours. During this period, adjust the pH value of the mixed solution with a 5% aqueous solution of orthophosphoric acid, and add a certain amount of deionized water to make the pH value of the mixed solution 1 and the total volume to be 80 ml. After the stirring was stopped, the container containing the mixed solution was placed in a constant temperature water bath at 90° C., aged under ambient pressure for 8 hours, cooled to room...

Embodiment 3

[0041] Weigh a certain mass of cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O] and disodium phosphate [Na 2 HPO 4 12H 2 [0], be prepared with deionized water to be respectively 25 milliliters of cerium nitrate aqueous solution and disodium hydrogen phosphate aqueous solution that concentration is 0.1 mol / liter. Place the cerium nitrate solution in a beaker or Erlenmeyer flask, stir with a magnetic stirrer at a speed of 150 rpm, drop the disodium hydrogen phosphate solution into the cerium nitrate solution while stirring, and continue stirring 0.5 hours. During this period, adjust the pH of the mixed solution with a 5% orthophosphoric acid aqueous solution, and add a certain amount of deionized water to make the mixed solution have a pH of 1 and a total volume of 80 ml. After the stirring was stopped, the container containing the mixed solution was placed in a constant temperature water bath at 90°C, aged for 12 hours under ambient pressure, cooled to room temperature, and centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com