Cable sheath tube for ships and preparation method thereof

A technology of cable protection and casing, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor sealing effect, surface damage of ship steel structure, and reduced cable protection function, so as to improve creep resistance and improve use Performance, the effect of changing the installation route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

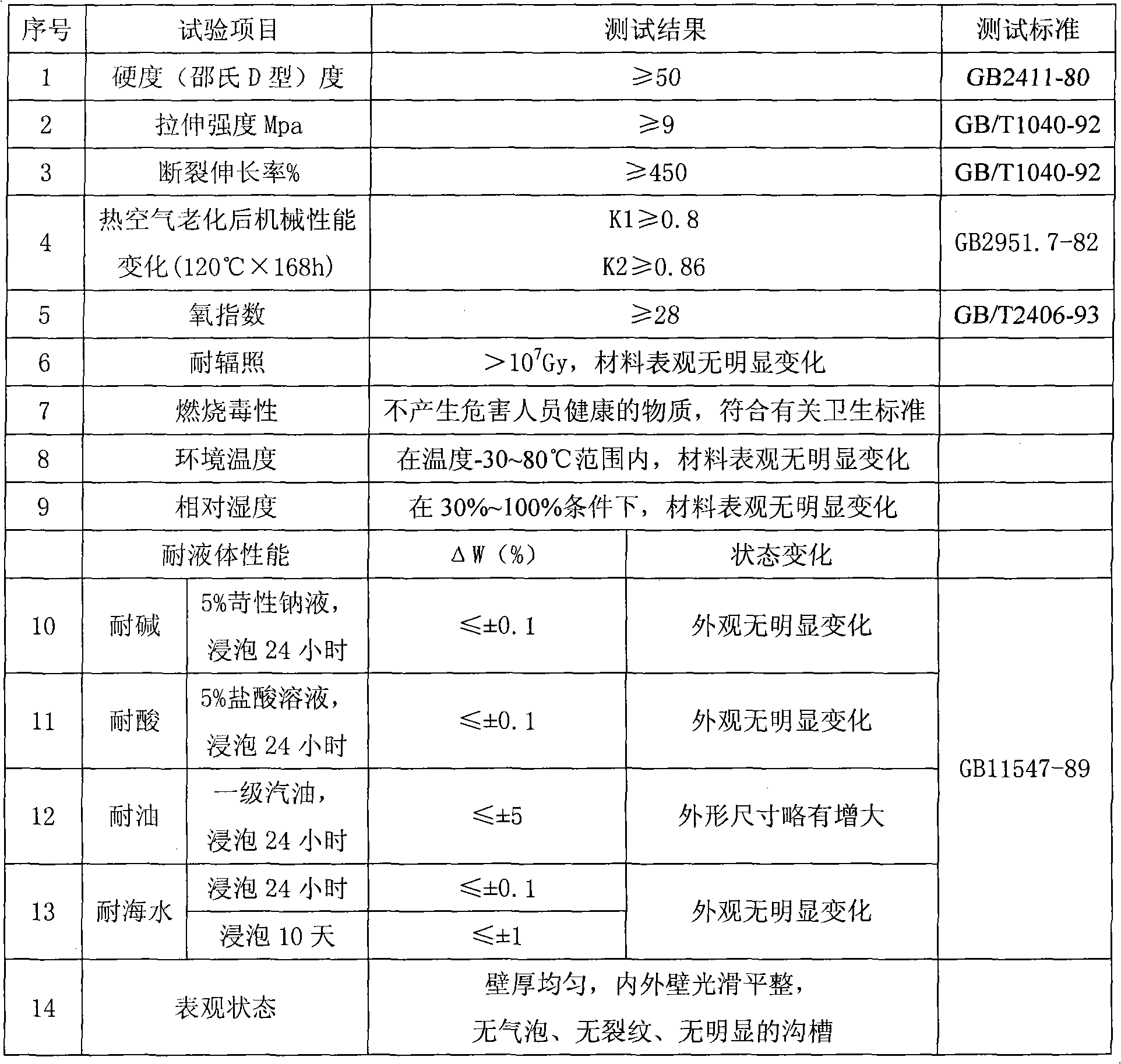

Examples

Embodiment 1

[0026] A cable sheath tube for ships, which is composed of basic resin, elastomer, antioxidant, light stabilizer, flame retardant system, softener, antifungal agent, radiation sensitizer and color masterbatch. After treatment, material mixing, granulation and drying, pipe forming and electron beam irradiation process, it is made into a cable sheath tube for ships.

[0027] Among them: the content of each component in the mixture is: 50 parts of low-density polyethylene (LDPE), 50 parts of ethylene-vinyl acetate copolymer (EVA), 10 parts of metallocene polyolefin elastomer (POE), EPDM rubber ( EPDM) 5 parts, nanoscale halogen-free composite flame retardant system (aluminum hydroxide / magnesium hydroxide 35 / 15) 50 parts, antioxidant (7910) 2 parts, light stabilizer (GW540) 1.5 parts, zinc oxide 2 parts , 2 parts of zinc stearate, 1.5 parts of salicylanilide, 2 parts of trimethylolpropane trimethacrylate (TMPTMA), 6 parts of masterbatch.

[0028]According to the above formula, th...

Embodiment 2

[0030] A cable sheath tube for ships, which is composed of basic resin, elastomer, antioxidant, light stabilizer, flame retardant system, softener, antifungal agent, radiation sensitizer and color masterbatch. After treatment, material mixing, granulation and drying, pipe forming and electron beam irradiation process, it is made into a cable sheath tube for ships.

[0031] Among them: the content of each component in the mixture is: 60 parts of low-density polyethylene (LDPE), 40 parts of ethylene-vinyl acetate copolymer (EVA), 8 parts of metallocene polyolefin elastomer (POE), EPDM rubber ( EPDM) 5 parts, nanoscale halogen-free composite flame retardant system (aluminum hydroxide / magnesium hydroxide 40 / 20) 60 parts, antioxidant (7910) 3 parts, light stabilizer (GW540) 2 parts, zinc oxide 2 parts , 3 parts of zinc stearate, 1.5 parts of salicylanilide, 4 parts of trimethylolpropane triacrylate (TMPTA), and 8 parts of masterbatch.

[0032] According to the above formula, the r...

Embodiment 3

[0034] A cable sheath tube for ships, which is composed of basic resin, elastomer, antioxidant, light stabilizer, flame retardant system, softener, antifungal agent, radiation sensitizer and color masterbatch. After treatment, material mixing, granulation and drying, pipe forming and electron beam irradiation process, it is made into a cable sheath tube for ships.

[0035] Among them: the content of each component in the mixture is: 55 parts of low-density polyethylene (LDPE), 45 parts of ethylene-vinyl acetate copolymer (EVA), 12 parts of metallocene polyolefin elastomer (POE), EPDM rubber ( EPDM) 3 parts, nanoscale halogen-free composite flame retardant system (aluminum hydroxide / magnesium hydroxide 45 / 25) 70 parts, antioxidant (7910) 2 parts, light stabilizer (GW540) 2 parts, zinc oxide 2 parts , 3 parts of zinc stearate, 2 parts of salicylanilide, 4 parts of trimethylolpropane trimethacrylate (TMPTMA), 8 parts of masterbatch.

[0036] According to the above formula, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com