Genetic engineering bacteria for producing D-lactic acid and constructon method and application thereof

A technology of genetically engineered bacteria and lactic acid, applied in the field of genetic engineering, can solve problems such as lack, and achieve the effects of improving production capacity, reducing costs, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

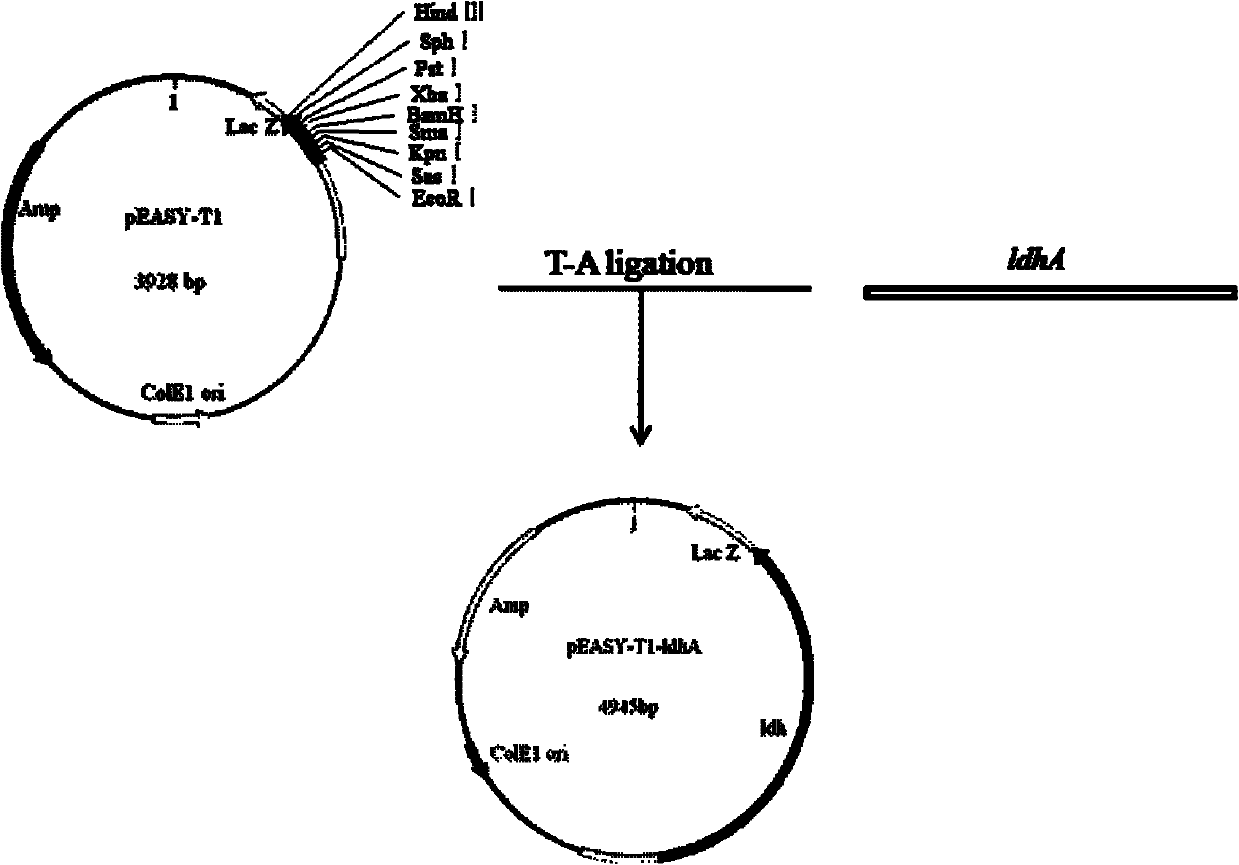

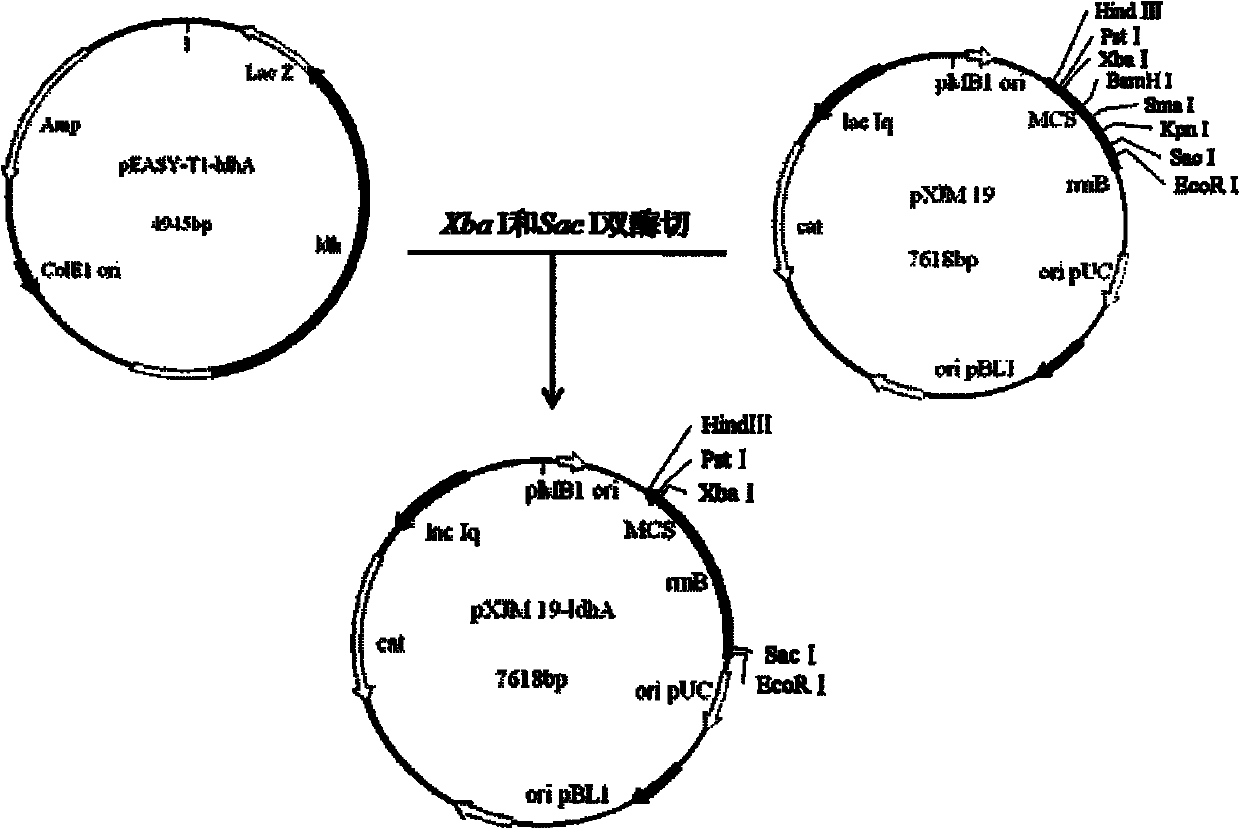

[0035] Embodiment 1: Construction of gene knockout vector:

[0036] 1. Cloning of D-lactate dehydrogenase gene in Lactobacillus bulgaricus

[0037] (1) According to the DNA sequence of the ldhA gene in Lactobacillus bulgaricus ATCC 11842 (NCBI-GI: 4085369), design primers to amplify its structural gene by PCR. The primer sequences are as follows:

[0038] primer1: 5′-GGCTAG GAGCTC TGTAAGAAAATCTGTAGGT-3′ (the underline is the introduced Sac I restriction site)

[0039] primer2: 5′-TGAGC TCTAGA AAAGGAGGAGGGACAArTAATGACT-3′ (the underline is the introduced Xba I restriction site)

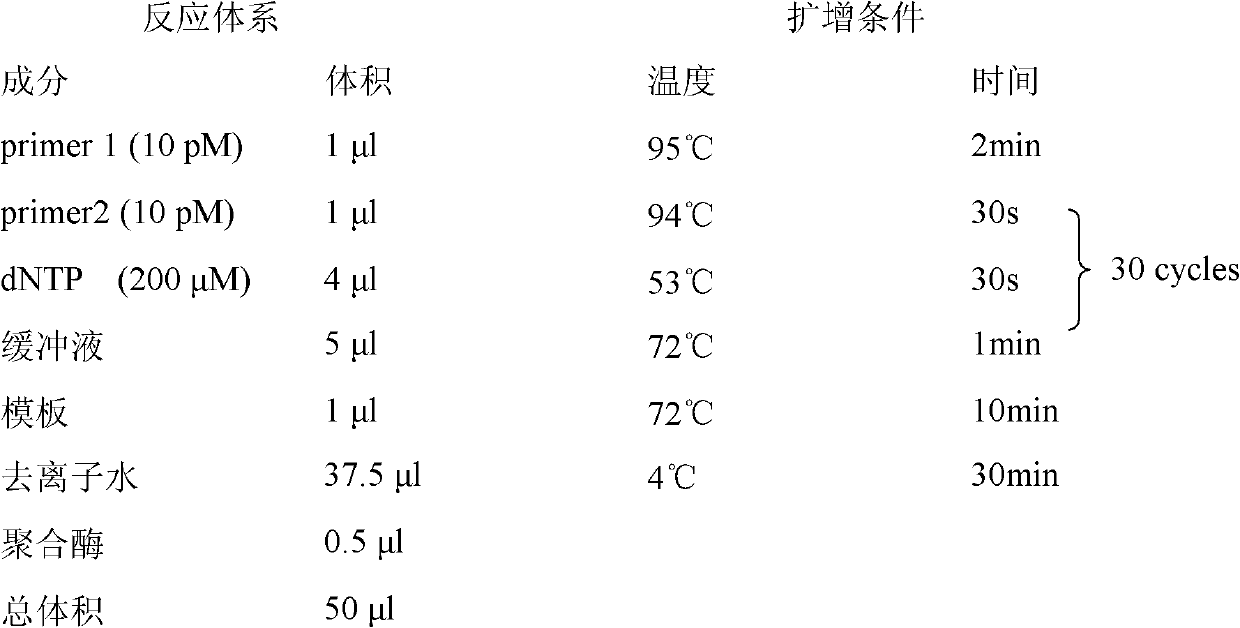

[0040] Using the genomic DNA of Lactobacillus bulgaricus ATCC 11842 as a template, under the guidance of primers primer1 and primer2, the ldhA gene sequence was cloned by PCR. The amplification conditions and system of PCR were as follows:

[0041]

[0042] The PCR product obtained is detected by 1% agarose gel electrophoresis, and the electrophoresis band with a size of about 1000bp is obtaine...

Embodiment 2

[0047] Embodiment 2: Screening of ldhA gene recombinant strain

[0048] The constructed D-lactate dehydrogenase gene expression vector pXJM 19 was electrotransformed into competent cells of Corynebacterium glutamicum Res 167Δldh, the transformation conditions were: 25δF, 600Ω, 2.5k V electric shock, pulse time 10-12ms, The bacterial solution was spread on a BHIS plate with 10 μg / ml chloramphenicol and cultured for 24 hours, the positive colonies were selected, the plasmid was extracted, and PCR amplification was performed with primers primer1 and primer2. The amplification results were in line with the expected values, indicating that the picked positive colony was the strain introduced with the recombinant vector pXJM19-ldhA, which was named C. glutamicum Res 167Δldh / ldhA.

Embodiment 3

[0049] Embodiment 3: the fermentation test of recombinant bacterial strain

[0050] (1) Seed medium formula (g / L): glucose 40, urea 2, casamino acid 7, yeast extract 2, dipotassium hydrogen phosphate 0.5, potassium dihydrogen phosphate 0.5, ferrous sulfate heptahydrate 6mg, seven Magnesium sulfate hydrate 0.5, manganese sulfate tetrahydrate 0.25, vitamin B 10.2mg, biotin 0.2mg, water 1000mL. Adjust pH 7.5.

[0051] (2) Fermentation medium (g / L): glucose 40, dipotassium hydrogen phosphate 0.5, potassium dihydrogen phosphate 0.5, ferrous sulfate heptahydrate 6 mg, magnesium sulfate heptahydrate 0.5, manganese sulfate tetrahydrate 0.25, vitamin B10. 2mg, biotin 0.2mg, water 1000mL. Adjust pH 7.5.

[0052] 1. Preparation of seeds:

[0053] With seed medium, each 1L Erlenmeyer flask is filled with 300mL medium, wrapped and sterilized. Take out the slant with bacteria stored in the refrigerator, add 1mL sterile water to each test tube, and scrape off the bacterium on the slant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com