Method for catalyzing and synthesizing octenyl succinic anhydride modified starch ester through yeast show lipase

A technology of octenyl succinic acid and lipase genes, which is applied in the field of bioengineering, can solve the problems of complicated and time-consuming immobilization process, high production cost, and limited commercial application, so as to achieve improved operation stability, low production cost, and high reaction rate. The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of Yeast Displaying Lipase

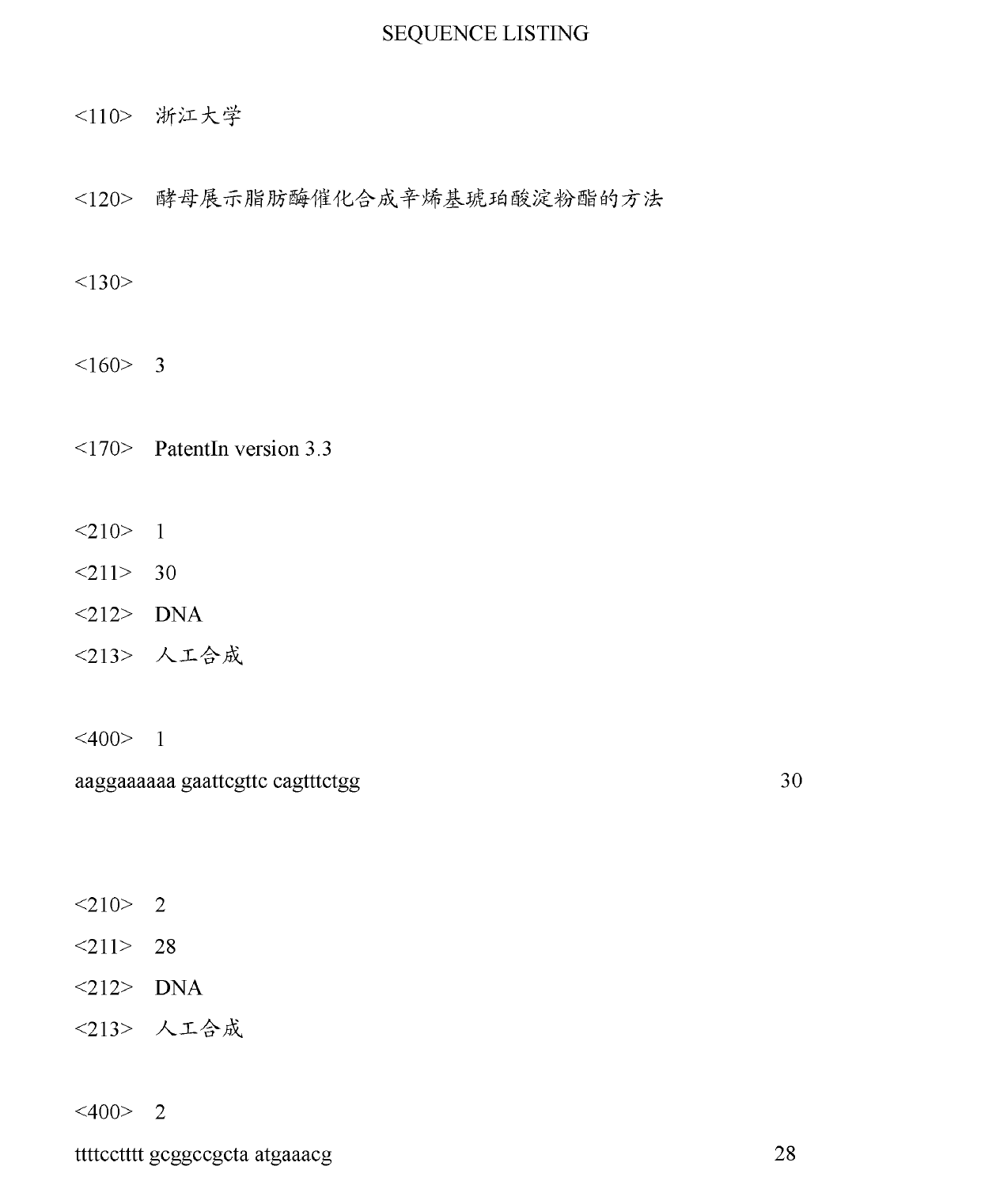

[0018] Synthesize the lipase gene (Genbank number: AF229435) of Rhizopus oryzae and the cell wall α-lectin gene of Pichia pastoris GS115 (Genbank number: M28164) by artificial synthesis, and add Connect the peptide sequence GSSGGSGGSGGSGGSGS(linker), and get the nucleotide sequence pro-ROL-linker-α-agglutinin after connection, and add EcoR I and Not I restriction sites at both ends of the sequence, where pro-ROL is the lipase gene , α-agglutinin is the cell wall α lectin gene.

[0019] Using the above artificially synthesized sequence as a template, PCR amplification was performed using the following primer pair,

[0020] Upstream primer: 5'-AAGGAAAAAAAGAATTCGTTCCAGTTTCTGG-3';

[0021] Downstream primer: 5'-TTTTCCTTTTGCGGCCGCTAATGAAACG-3'

[0022] The PCR reaction system is: 1 μl of template DNA, 0.5 μl of high-fidelity DNA polymerase, 0.4 μl of dNTP (50 mM), 0.5 μl of upstream and downstream primers, 5 μl of 10×PCR ...

Embodiment 2

[0026] Example 2 Yeast shows lipase catalyzed synthesis of octenyl succinic acid starch ester

example 1

[0027] Example 1 Get 350g of corn starch and prepare 35% starch milk (starch dry basis) with water, absorb water at 65°C for 15 minutes to make the starch milk absorb water and swell, add 1g of the above-mentioned prepared yeast to display lipase after cooling, then add 10g of starch in batches Alkenyl succinic anhydride, placed in a 85-1 type magnetic stirrer to start the reaction, the rotation speed was 100 rpm, the reaction temperature was kept at 34°C, the stirring was stopped after 1 hour of reaction, the pH value was adjusted to 7.0, after precipitation, washing, Spray drying to obtain powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com