Heat-resisting urate oxidase gene of microbacterium category bacteria and application of same

A uric acid oxidase and heat-resistant technology, which is applied in genetic engineering, plant gene improvement, enzymes, etc., can solve the problems of unfavorable storage and use of enzymatic uric acid detection kits, short half-life, poor thermal stability, etc., and achieve excellent thermal stability. The effect of stability and catalytic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the separation of producing thermostable urate oxidase bacterial strain:

[0034] Take 2.0 grams of soil (taken from the surrounding areas of Hangzhou) and inoculate it into 10 mL of enriched medium with uric acid as the only carbon source (uric acid, 5.0 g; yeast extract, 0.5 g; NaCl, 0.1 g; MgSO 4 .7H 2 O, 0.5g; K 2 HPO 4 , 2.0g; KH 2 PO 4 , 0.5g; H 2 O, the volume was adjusted to 1000 mL; pH 7.5, high-temperature and high-pressure sterilization was carried out according to the conventional method), and cultured on a shaking table at 30°C.

[0035] Three days later, 1 mL of the culture solution was inoculated on 10 ml of the same sterilized medium as above, and the culture was continued (shaking culture at 30° C. for 3 days).

[0036] Repeat this three times (i.e. repeat the above-mentioned continuous culture step 2 times) and then use an inoculation loop to dip a ring of enrichment culture, and in the solid separation medium (uric acid, 3.0g; yeas...

Embodiment 2

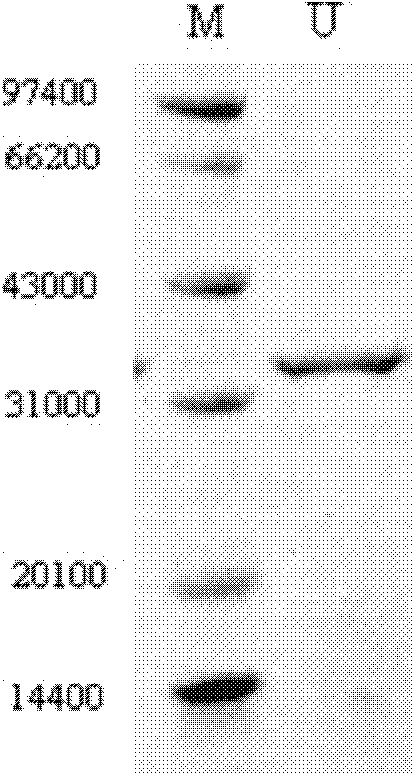

[0041] Embodiment 2, the purification of thermostable urate oxidase

[0042] With the enzyme fermentation condition (substratum consists of: uric acid, 3g; Corn steep liquor, 10g; K 2 HPO 4 · 3H 2 O, 2g; KH 2 PO 4 , 0.5g; MgSO 4 · 7H 2 O, 0.5 g; NaCl, 1 g; Water, 1000 mL; pH 7.5. Optimal culture condition is: culture temperature 30 ℃,) culture 10L fermented liquid, be specifically: get 10ml bacterial liquid and add in the culture medium of 100ml, ferment and cultivate 1 day at 30 ℃; Obtain 10L fermented liquid after merging.

[0043] The bacteria were collected by centrifugation at 5000rpm for 30min, and the cells were washed twice with 50mmol / L, pH7.5 phosphate buffer, and then suspended in 2 times the volume of buffer. After crushing the cells with a high-pressure cell disruptor, centrifuge at 5000 rpm for 50 min to remove cell debris to obtain a crude enzyme solution.

[0044] Add solid ammonium sulfate to the crude enzyme solution to make the saturation of solid ...

Embodiment 3

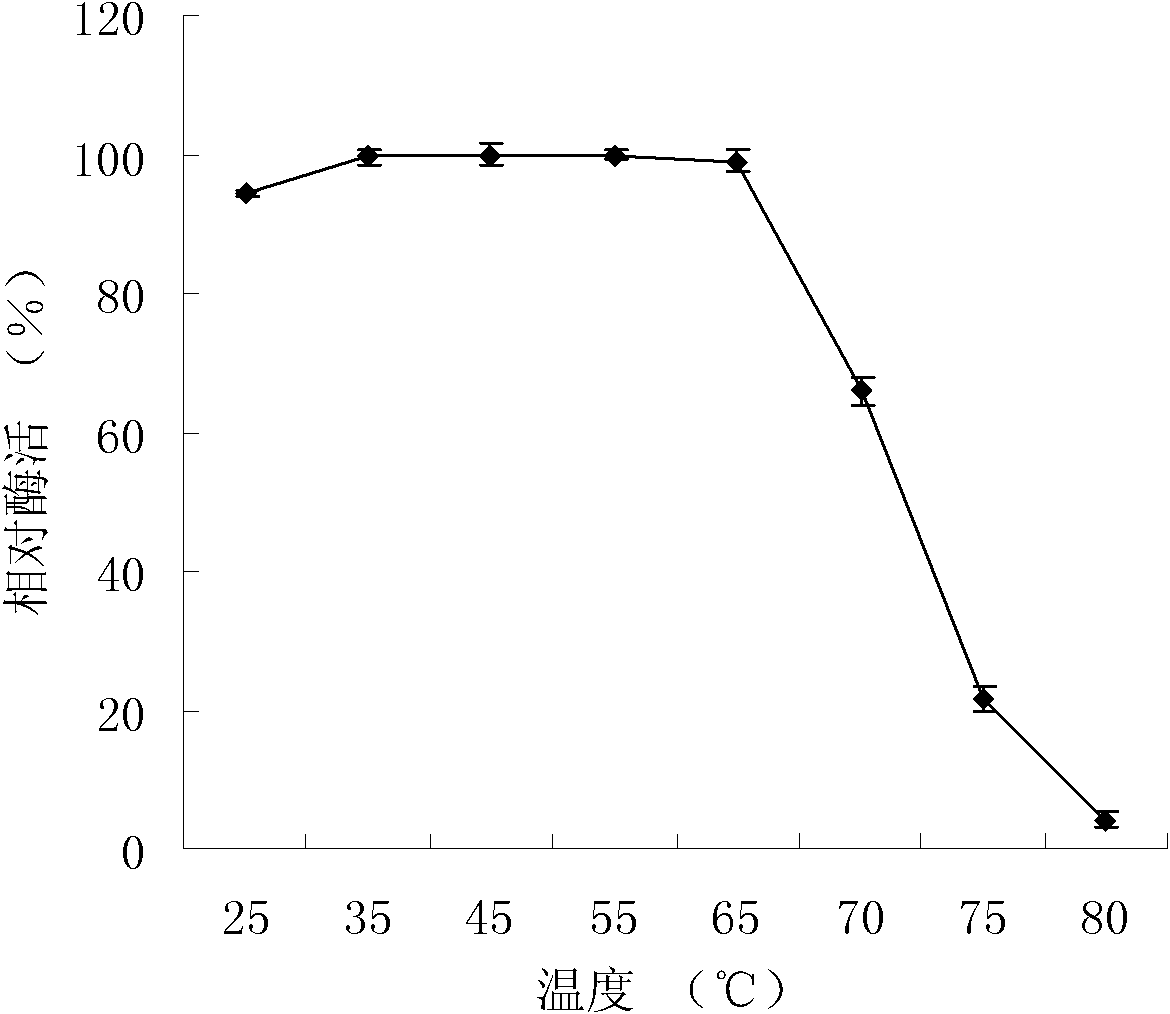

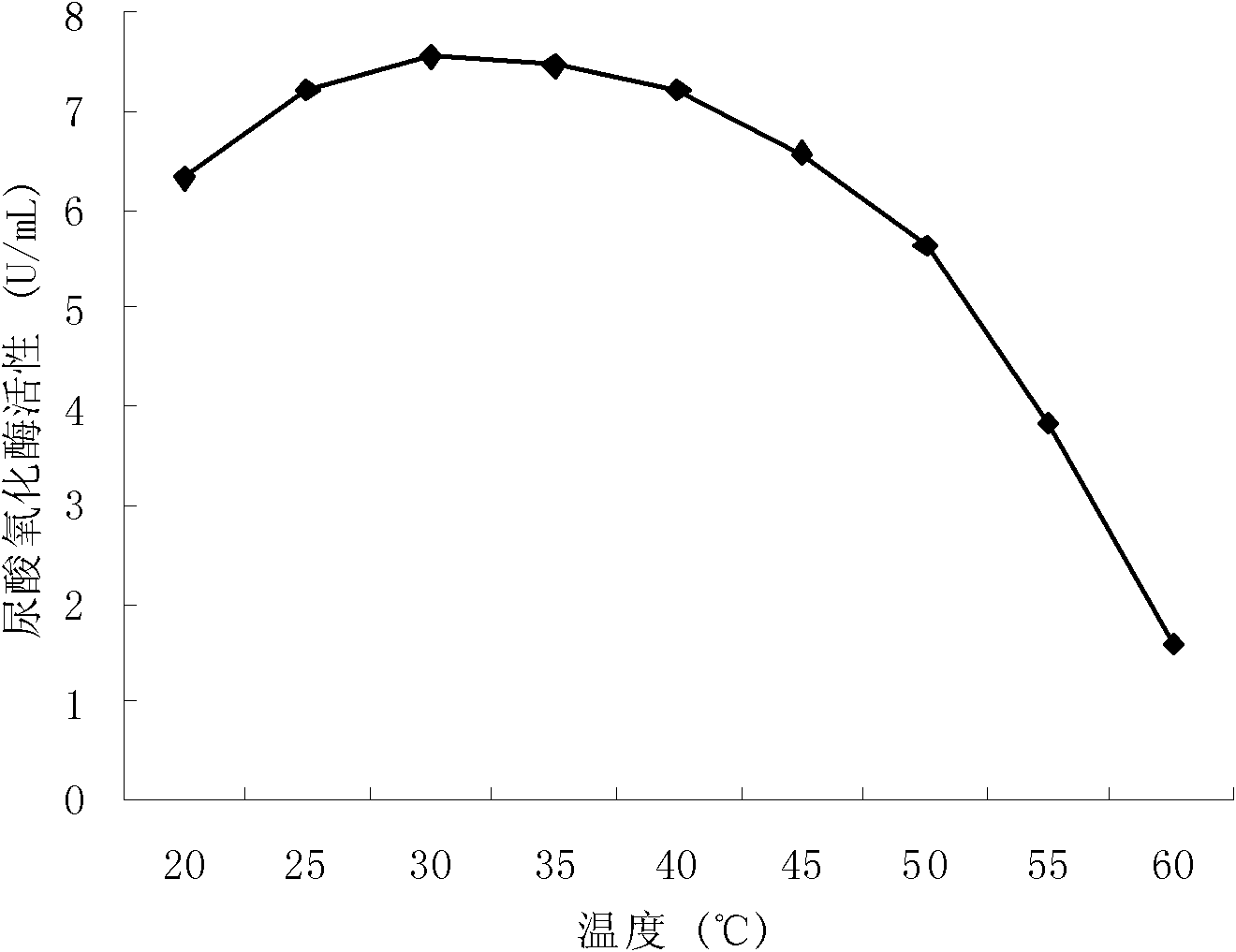

[0047] Embodiment 3: thermostability and optimal reaction temperature of enzyme:

[0048] The remaining enzyme activity was determined after treatment at different temperatures for 30 min in sodium borate buffer at pH 8.5. The result is as figure 2 As shown, the enzyme can retain 64% of the enzyme activity after being treated at 70°C for 30 minutes. Uric acid oxidase activity was measured at different temperatures, the results are shown in image 3 , the optimum temperature for enzyme action is 30°C.

[0049] The pH stability of the enzyme and the optimum pH of the enzyme reaction:

[0050] Different buffers at different pH values (pH 3.0-6.0: 0.1M citric acid buffer; pH 6.0-8.5: 0.1M phosphate buffer; pH 8.5-9.5: 0.05M boric acid buffer; pH 9.5-11.0: 0.05M Borax buffer) was added to the enzyme solution, incubated at room temperature for 18 hours, and the remaining enzyme activity was determined. The result is as Figure 4 It was shown that the enzyme was stable at pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com