Production method of lactic acid and polylactic acid

A manufacturing method, a technology for polylactic acid, applied in the directions of organic chemistry methods, chemical instruments and methods, separation/purification of carboxylic acid compounds, etc., can solve the problems of undisclosed impurities, thermal stability, mechanical strength, influence of color tone, high price, Huge cost and other issues, to achieve the effects of excellent thermal stability, improved productivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to the following examples.

[0182] In this example, as a microorganism having an L-lactic acid fermenting ability, an Xenopus laevis-derived L-lactate dehydrogenase gene (L-LDH gene) having the base sequence shown in SEQ ID NO: 1 was used. Saccharomyces cerevisiae in Saccharomyces cerevisiae.

reference example 1

[0183] (Reference Example 1) Preparation of Yeast Strain Having L-lactic Acid Fermentation Ability

[0184] A strain obtained by breeding the B3 strain described in JP-A-2008-029329 in a culture medium was used as a yeast strain having L-lactic acid fermentation ability. The breeding method is as follows.

[0185] First, in the B3 strain, the L-LDH gene described in SEQ ID NO: 1 was introduced into the SED1 locus. The introduction into the SED1 locus is carried out as follows: using pTRS102 described in JP-A-2008-029329 as an amplification template, using PCR using oligonucleotides (SEQ ID NO: 2, 3) as a primer set, for the gene containing The PCR fragment of 1.3kb of L-LDH gene and TDH3 terminator sequence of Xenopus laevis was amplified. Here, SEQ ID NO: 2 is designed to add a sequence equivalent to 60 bp upstream from the initiation codon of the SED1 gene.

[0186] Next, using plasmid pRS423 as an amplification template, a PCR fragment of about 1.3 kb including the HIS3 ...

reference example 2

[0211] (Reference Example 2) Production of L-lactic acid by batch fermentation

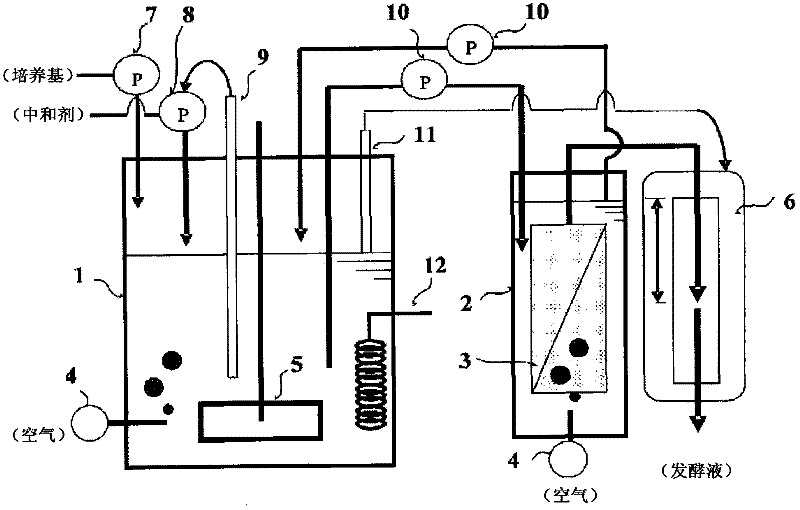

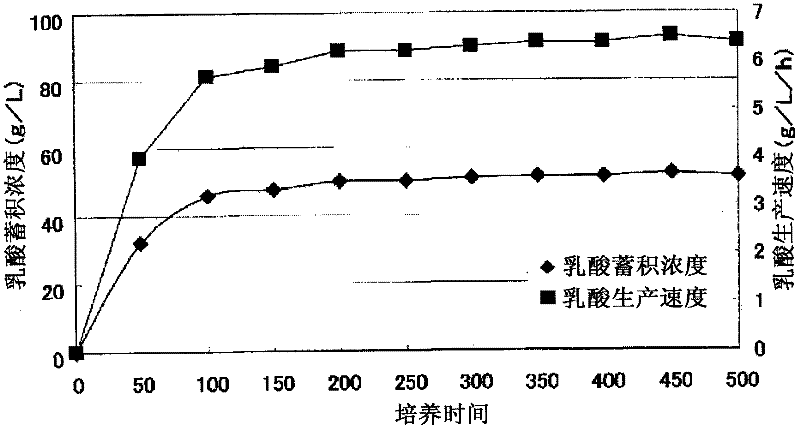

[0212] Using the HI003 strain prepared in Reference Example 1, a batch fermentation test was performed using a raw material sugar medium (70 g / L saccharin (manufactured by Muso Co., Ltd.), 1.5 g / L ammonium sulfate). This medium was used after autoclaving (121°C, 15 minutes). The concentration of lactic acid as a product was evaluated using HPLC shown in Reference Example 1, and the glucose concentration was measured using Glucose test Wako C (manufactured by Wako Pure Chemical Industries, Ltd.). The operating conditions of the batch fermentation apparatus of Reference Example 2 are shown below.

[0213] Reaction tank capacity (amount of lactic acid fermentation medium): 2 (L), temperature adjustment: 32 (°C), reaction tank ventilation: 0.1 (L / min), reaction tank stirring speed: 200 (rpm), pH adjustment: use 1N calcium hydroxide to adjust to pH5.

[0214] First, the HI003 strain was cultured ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com