Polyacrylate super absorbent resin and preparation method thereof

A technology of superabsorbent resin and polyacrylate, which is applied in the field of water-absorbent resin, can solve the problems of high product monomer residue, high process control requirements, and high control requirements, so as to promote deep thermal polymerization crosslinking reaction and reduce residual monomer. Body, controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

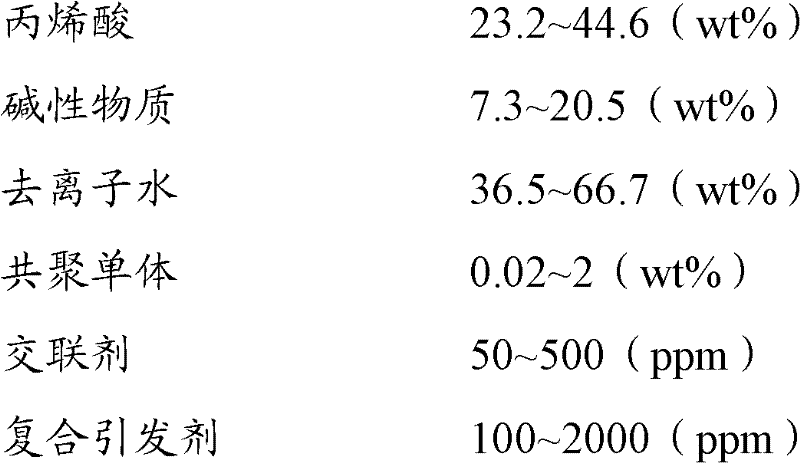

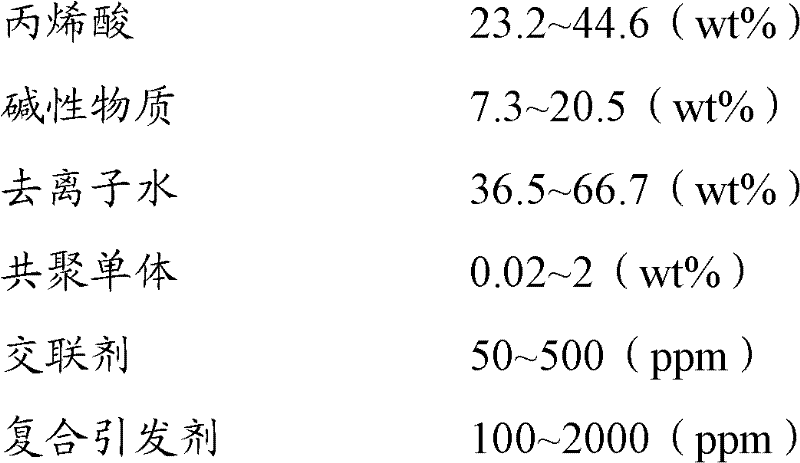

Method used

Image

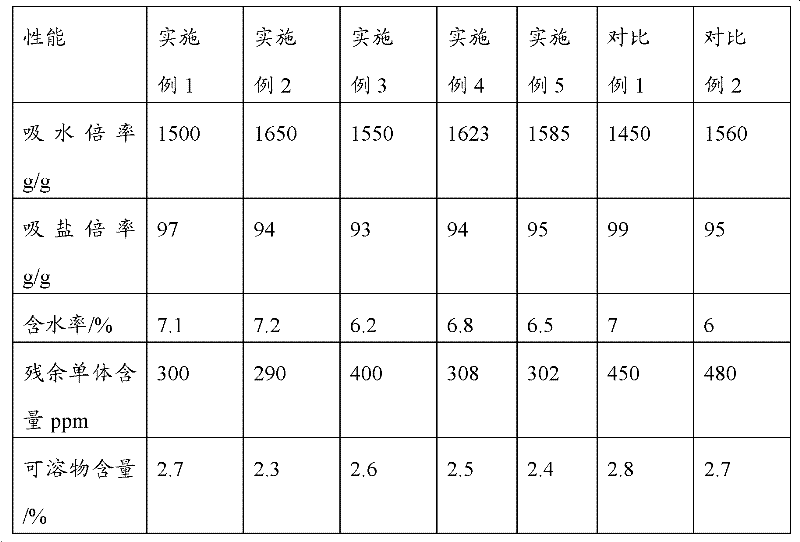

Examples

Embodiment 1

[0034]Weigh 1800g of acrylic acid in a container with stirring, cooling, and thermometer for temperature measurement, then weigh 2343.75g of 32% sodium hydroxide aqueous solution by weight, dilute with 1475g of deionized water, and gradually add it to high-purity acrylic acid For neutralization, pay attention to control the temperature of the neutralization system not to exceed 35°C. After the neutralization reaction is completed, add 12.5g of comonomer acrylamide and 100ppm of crosslinking agent (which contains N,N'-methylenebisacrylamide 10ppm, polyethylene glycol diacrylate 90ppm), photoinitiator benzoin isopropyl ether 50ppm, thermal initiator 190ppm (ammonium persulfate 30ppm, hydrogen peroxide 80ppm, sodium bisulfite 80ppm), stirred to the above It can be fully dissolved and mixed evenly, and put into a transparent container; then put the transparent container under ultraviolet light for about 15 minutes, when the temperature in the container reaches 80°C, remove the irra...

Embodiment 2

[0036] In a container with stirring, cooling, and thermometer temperature measurement, weigh 936.7g of acrylic acid, then weigh 1473.70g of potassium hydroxide aqueous solution with a mass percentage of 20%, dilute it with 1938.00g of deionized water, and gradually add it to the high-purity Neutralize in acrylic acid, pay attention to control the temperature of the neutralization system not to exceed 35°C, after the neutralization reaction is completed, add 24.8g of comonomer polyvinyl alcohol, crosslinking agent N-methylolacrylamide 50ppm, photoinitiator 2-Hydroxy-2-methyl-1-phenylacetone 50ppm, thermal initiator potassium persulfate 1000ppm, stir until the above substances can be fully dissolved and mixed evenly, put into a transparent container; then put the transparent container under ultraviolet light After irradiating for about 30 minutes, when the temperature in the container reaches 85°C, remove the irradiated ultraviolet light source and let it stand for 5 hours to obt...

Embodiment 3

[0038] In a container with stirring, cooling, and thermometer temperature measurement, weigh 1009.38g of acrylic acid, then weigh 1730.29g of a 35% aqueous sodium hydroxide solution, dilute it with 2059.13g of deionized water, and gradually add it to the high-purity Neutralize in acrylic acid, pay attention to control the temperature of the neutralization system not to exceed 35°C, after the neutralization reaction is completed, add 35.11g of comonomer acrylamide, 500ppm of crosslinking agent (containing 100ppm of hydroxyethyl acrylate, ethylene glycol Diacrylate 100ppm, ethylene glycol 100ppm, glycerin 100ppm, allyl acrylate 100ppm), photoinitiator 160ppm (including benzophenone 50ppm, 2-isopropylthioxanthone 110ppm), thermal initiator 1500ppm (including 470ppm of ammonium persulfate, 800ppm of hydrogen peroxide, and 230ppm of sodium bisulfite), stir until the above substances can be fully dissolved and mixed evenly, and put into a transparent container; then put the transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com