Super capacitor electrode material and super capacitor electrode production method

A technology for supercapacitors and electrode materials, applied in the field of material science, can solve the problems of difficult application of supercapacitors, difficult quality control, and difficult to guarantee the source of carbon materials, etc., to achieve the effect of improving cycle performance, not easy to drop powder, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] a. Preparation of electrode slurry

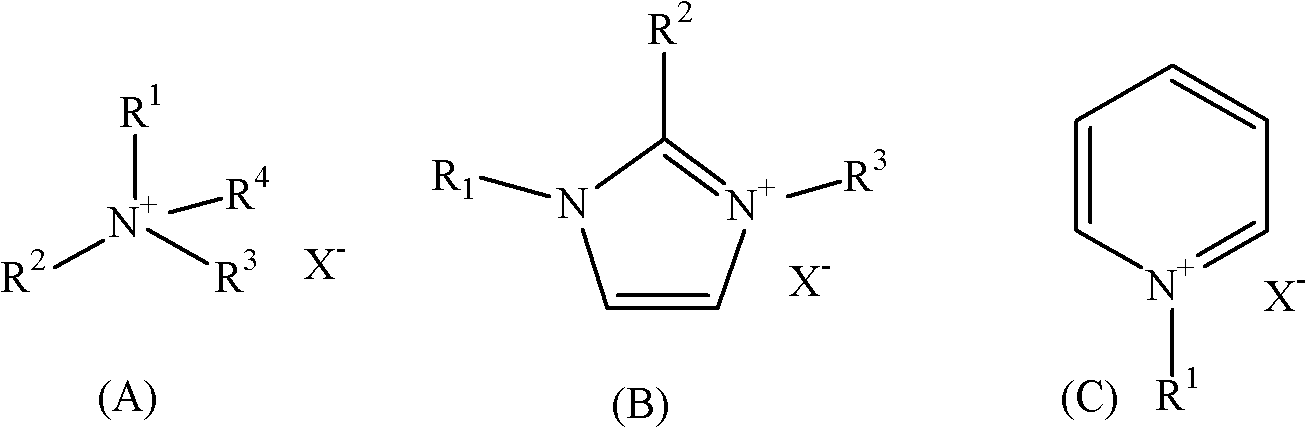

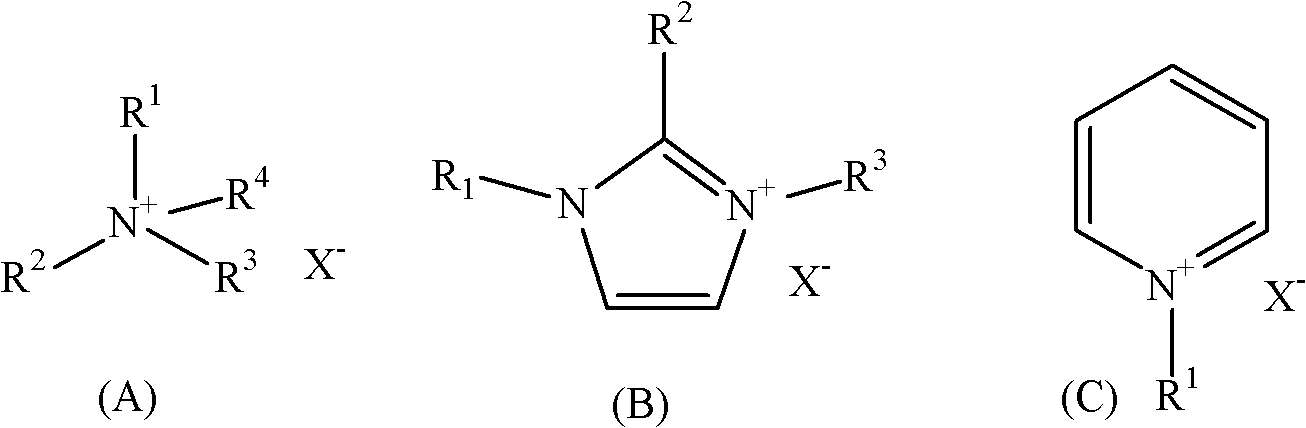

[0035] Activated carbon (100 g), acetylene black (5 g), and 1-methyl-3-octylimidazolium tetrafluoroborate (9 g) were added to a ball mill, and a grinding treatment with a residence time of 1 hour was performed.

[0036] Add PTFE (6 grams), ethanol (40 grams) and deionized water (30 grams) to the mixture, grind for 40 minutes, then add deionized water (30 grams) to the mixture, and continue grinding for 1 hour to obtain electrode slurry material.

[0037] b. Electrode preparation

[0038] On an aluminum foil (thickness: 20 microns) as a current collector, the above-mentioned electrode slurry was evenly coated on both sides of the aluminum foil, and dried at 120°C for 5 minutes to obtain a pole piece with a thickness of 175 microns (including the aluminum foil).

[0039] On a press, the electrode pole piece is subjected to calendering treatment to form an electrode layer with a thickness of 120 microns to obtain the electrode pole pi...

Embodiment 2

[0042] a. Preparation of electrode slurry

[0043] Activated carbon (100 g), ketjen carbon black (6 g), and 1-methyl-3-dodecylimidazolium tetrafluoroborate (8 g) were added to a ball mill for grinding with a residence time of 1 hour.

[0044] Add PVDF (5 g), ethanol (30 g) and deionized water (30 g) to the mixture, grind for 40 minutes, then add deionized water (35 g) to the mixture, and continue grinding for 1 hour to obtain electrode slurry material.

[0045] b. Electrode preparation

[0046] Electrodes were prepared in the same manner as in Example 1.

Embodiment 3

[0048] a. Preparation of electrode slurry

[0049] Add activated carbon (100 g), ketjen carbon black (4 g), acetylene black (1.5 g), N-dodecyl-N, N-dimethylbenzyl ammonium tetrafluoroborate (10 g) in the ball mill ), the residence time is 1.5 hours of grinding treatment.

[0050] Add PTFE (5 grams), CMC (1 gram), Virahol (30 grams) and deionized water (50 grams) in this mixture, grind 40 minutes, and then add deionized water (30 grams) to this mixture, Continue grinding for 1 hour to obtain electrode slurry.

[0051] b. Electrode preparation

[0052] Electrodes were prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com