Preparation method for polymer grafted graphene oxide

A graphene and polymer technology, applied in the field of preparation of inorganic-organic hybrid materials, can solve the problems of high price, difficulty, and difficulty in removing organic solvents, and achieve the effects of simple steps, safe reaction, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for polymer-grafted graphene oxide, comprising the steps of:

[0033] (1) At first graphite is pre-oxidized with phosphorus pentoxide, specifically graphite powder 5g, phosphorus pentoxide 1g; After reacting for 24 hours, filter and wash, and vacuum dry to obtain black pre-oxidized graphite powder;

[0034] (2) Add pre-oxidized graphite (5g) into concentrated sulfuric acid (100mL) and potassium permanganate (5g) in turn and stir for 2 hours, then slowly add 140mL of water into the above mixed solution (note that the solution is exothermic in large amounts at this time, and it takes There are protective measures), after adding water, continue to stir for 2 hours, then centrifuge to wash away manganese ions and acid; vacuum dry to obtain a tan product (that is, graphene oxide);

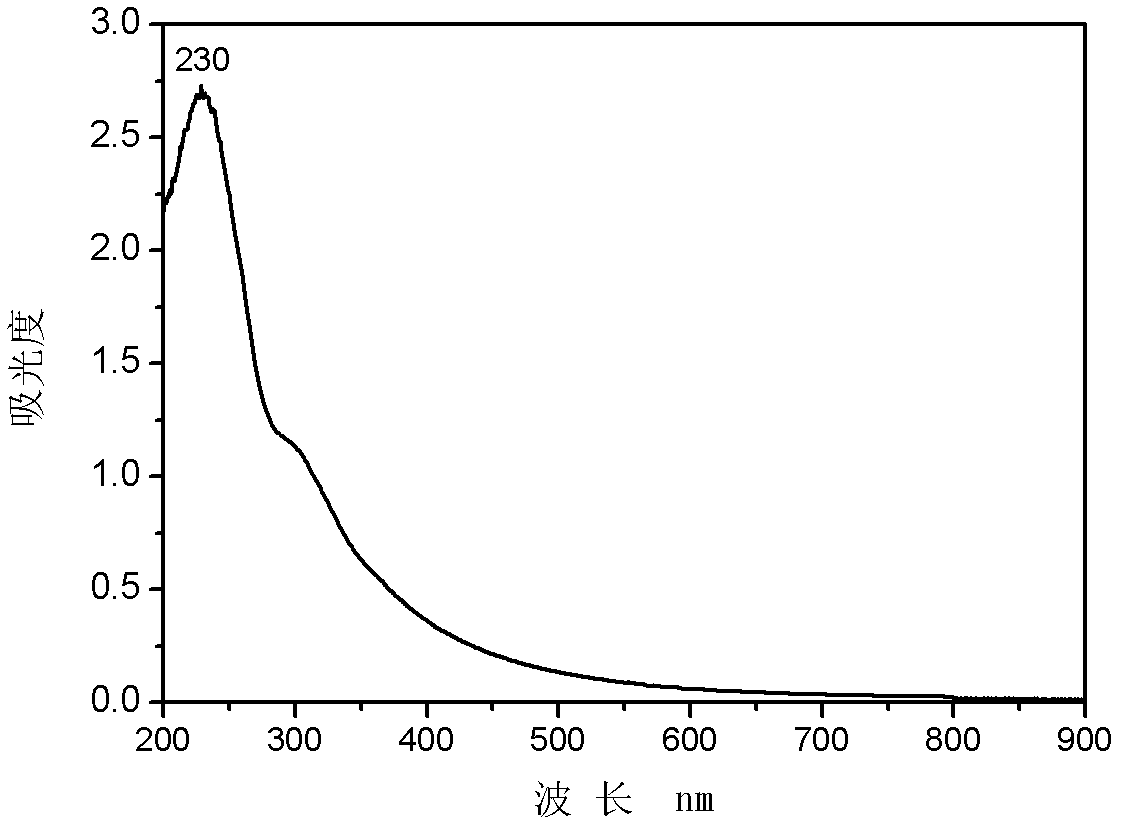

[0035] Test proves, the water solubility of above-mentioned product is very good; By figure 1 It can be seen that the graphene oxide aqueous solution has an ultraviolet abso...

Embodiment 2

[0041] A preparation method for polymer-grafted graphene oxide, comprising the steps of:

[0042] (1) Graphene oxide preparation method is with above-mentioned embodiment one;

[0043] (2) Utilize tetravalent cerium salt to graft polyacrylamide on the surface of graphite oxide;

[0044] The specific experimental steps are: equipped with mechanical stirring, reflux condenser and N 2 Add the above-mentioned graphene oxide (0.2g) and acrylamide monomer (2mL) into the three-necked reaction flask of the catheter, heat to 40 degrees, and pass N 2 After 15 minutes, the nitric acid solution of ammonium cerium nitrate was added dropwise, and the 2 Continue to stir for 1 to 5 hours;

[0045] After the reaction is over, since the polymer is insoluble in water, the successfully grafted product will precipitate out of water, filter the precipitate, and wash with water and ethanol in turn to remove unreacted monomers, trivalent, and tetravalent Cerium ions, etc.; finally, the grafted p...

Embodiment 3

[0047] A preparation method for polymer-grafted graphene oxide, comprising the steps of:

[0048] (1) Graphene oxide preparation method is with above-mentioned embodiment one;

[0049] (2) Utilize tetravalent cerium salt to graft polyacrylonitrile on the surface of graphite oxide;

[0050] The specific experimental steps are: equipped with mechanical stirring, reflux condenser and N 2 Add the above-mentioned graphene oxide (0.2g) and acrylonitrile monomer (2mL) into the three-necked reaction flask of the catheter, heat to 35 degrees, and pass N 2 After 15 minutes, the nitric acid solution of ammonium cerium nitrate was added dropwise, and the 2 Continue to stir for 1 to 5 hours;

[0051] After the reaction is over, since the polymer is insoluble in water, the successfully grafted product will precipitate out of water, filter the precipitate, and wash with water and ethanol in turn to remove unreacted monomers, trivalent, and tetravalent Cerium ions, etc.; finally, the gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com