EVA (ethylene vinyl acetate) adhesive film for solar cells

A technology of solar cells and adhesive films, applied in circuits, adhesives, photovoltaic power generation, etc., to achieve good stability and service life, excellent UV aging resistance, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

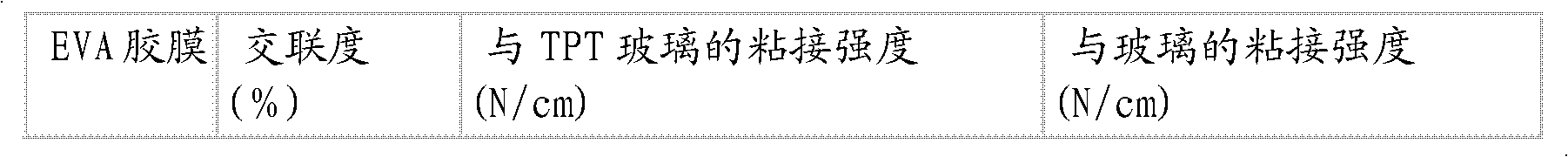

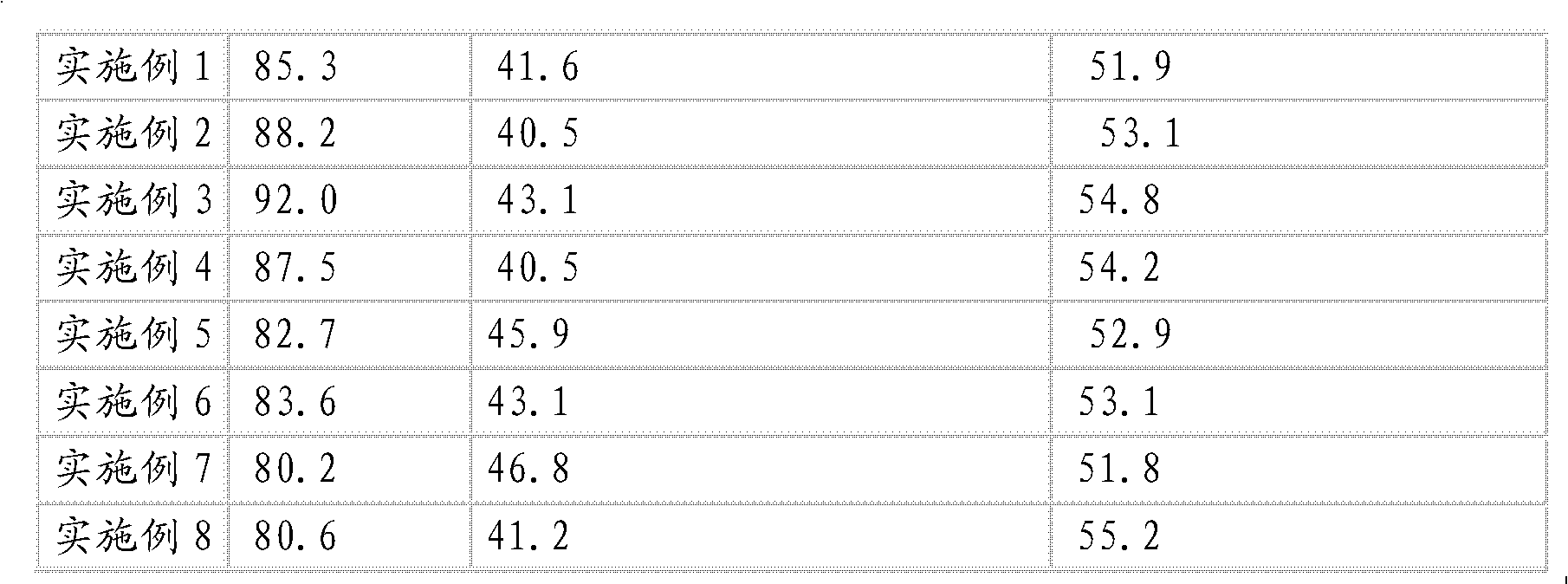

Examples

Embodiment 1

[0050] In terms of parts by mass, the following raw materials were weighed:

[0051] VA content is 34%, 100 parts of EVA pellets (ethylene-vinyl acetate copolymer) whose melt index value is 50g / 10min

[0052] Silane coupling 3-aminopropylmethyldiethoxysilane 0.01 parts by weight

[0053] 1.5 parts of cross-linking curing agent tert-butyl peroxide 2-ethylhexyl carbonate

[0054] 0.15 parts of cross-linking curing accelerator magnesium oxide

[0055] Heat stabilizer calcium-zinc composite liquid stabilizer 2 parts by weight

[0056] 0.2 parts of the tackifier r-glycidyl ether oxypropyltrimethoxysilane

[0057] 0.7 parts of the antioxidant β-(4-hydroxyl-3,5-di-tert-butylphenyl) n-octadecyl propionate

[0058] 0.01 parts of said hindered amine light stabilizer polysuccinate (4-hydroxyl-2,2,6,6-tetramethyl-1-piperidine ethanol) ester

[0059] 0.03 parts each of the ultraviolet absorber nano-scale titanium dioxide and 2-hydroxyl-4-n-dodecyloxybenzophenone

[0060] Prepare EVA ...

Embodiment 2

[0066] VA content is 37%, 100 parts of EVA pellets (ethylene-vinyl acetate copolymer) whose melt index value is 50g / 10min

[0067] Silane coupling agent 3-aminopropyltrimethoxysilane 2 parts by weight

[0068] Cross-linking curing agent 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane and 1,1-(diperoxy-tert-butyl)3,3,5-trimethylcyclohexane Alkanes each 1.0 parts

[0069] 0.25 parts of cross-linking curing accelerator triallyl isocyanurate

[0070] Thermal stabilizer barium-zinc composite liquid stabilizer 5 parts by weight

[0071] 0.6 parts of said tackifier vinyltrimethylsilane

[0072] One or two of each of 0.3 parts in the antioxidant distearyl pentaerythritol diphosphite and tris (nonylphenyl) phosphite

[0073] 0.1 parts of the hindered amine light stabilizer bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidinyl)decanediester

[0074] 0.04 parts each of the ultraviolet absorber nano-level aluminum oxide and 2-(2'-hydroxyl-3', 5'-di-tert-phenyl)-5-chlorinated benzotriazole

...

Embodiment 3

[0077] 100 parts of EVA pellets (copolymer of ethylene-vinyl acetate) with a melt index value of 50 g / 10 min at a VA content of 35 percent

[0078] Silane coupling agent N-(2-aminoethyl)-3-aminopropylmethyldimethoxysilane 1 part by weight

[0079] 2.0 parts of crosslinking curing agent 1,1-(diperoxy-tert-butyl) 3,3,5-trimethylcyclohexane

[0080] 0.25 parts of cross-linking curing accelerator triallyl cyanurate

[0081] 5 parts by weight of heat stabilizer rare earth liquid stabilizer

[0082] 0.4 parts of the tackifier γ-aminopropyltriethoxysilane

[0083] 0.4 parts of the antioxidant two (2,4-dicumylphenyl) pentaerythritol diphosphite

[0084] 0.05 parts of the hindered amine light stabilizer bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidyl)decanediester

[0085] 0.05 parts of the ultraviolet absorber 2-hydroxyl-4-n-octyloxybenzophenone

[0086] Prepared according to the method of Example 1, the extrusion temperature is controlled at 86° C., and the cross-linked EVA film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com