Film system structure for enhancing Terahertz radiation absorption rate and preparation method thereof

A technology of terahertz radiation and film structure, which is applied in the field of film structure and its preparation to enhance the absorption rate of terahertz radiation, can solve the problems of low reflectivity, hinder heat transmission, large thermal resistance, etc., so as to improve the surface body of the film. ratio, the preparation process is simple and reasonable, and the effect of increasing the absorption rate of terahertz radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

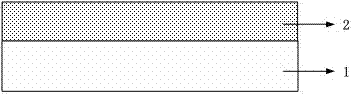

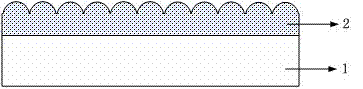

[0038] As shown in Figure 2, a film structure for enhancing the absorption rate of terahertz radiation includes a dielectric thin film and a terahertz absorbing layer, and the structure is deployed on the top layer of the detection unit of the terahertz microarray detector.

[0039] The detection unit of the terahertz microarray detector such as Figure 2-a shown. The array unit is prepared on the silicon wafer with the underlying readout circuit 4, wherein the readout circuit has an interface 5 with the subsequent MEMS device, and then grows a sacrificial layer 6, a supporting layer 7, metal electrodes and leads 8, and a sensitive film 9 etc. and graph them separately. The sacrificial layer material can be silicon oxide film or photosensitive polyimide (PSPI) material; the support layer material is composed of silicon nitride, silicon oxide or multi-layer composite film; the metal electrode is aluminum, titanium, nickel-chromium alloy, etc. ; Sensitive films are vanadium ox...

Embodiment 2

[0045] As shown in Fig. 3, a film structure for enhancing the absorption rate of terahertz radiation includes a dielectric film and a terahertz absorbing layer, and the structure is deployed on the top layer of the pyroelectric terahertz detection unit.

[0046] Pyroelectric terahertz detection unit such as Figure 3-a shown. The completed process is: remove a part of the semiconductor substrate 12 by chemical etching, and then prepare the silicon dioxide dielectric layer 13 , the lower electrode 14 , the lithium tantalate pyroelectric thin film 15 and the upper electrode 16 . Clean the top surface of the detection unit to remove surface contamination, and bake the substrate at 200°C to remove surface moisture and enhance the adhesion of the dielectric film.

[0047] The silicon oxide dielectric thin film 17 is prepared by PECVD frequency mixing growth technology. Two sets of power sources with different frequencies are used to work alternately, among which, the frequency of...

Embodiment 3

[0051] As shown in Figure 4, a film structure for enhancing the absorption rate of terahertz radiation includes a dielectric thin film and a terahertz absorbing layer, and the structure is developed on the top layer of the lithium tantalate crystal sheet sensitive element.

[0052] The preliminary preparation process of lithium tantalate crystal sheet sensitive element is as follows: Figure 4-a~Figure 4-c shown. The preparation process is as follows: the lower electrode 20 is prepared on the lithium tantalate wafer 19, and the lithium tantalate wafer is bonded to the silicon substrate 22 with a BCB polymer material 21, such as Figure 4-a Shown; Lithium tantalate wafer is thinned by grinding and polishing, such as Figure 4-b Shown; Prepare upper electrode 23, as Figure 4-c shown.

[0053] The silicon nitride dielectric thin film 24 is prepared by PECVD frequency mixing growth technology. Two sets of power sources with different frequencies are used to work alternately, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com