Modified zeolite filling material BMZ-1 and its preparation method and application

A technology for modifying zeolite and zeolite powder, applied in chemical instruments and methods, other chemical processes, silicates, etc., can solve the problems of high framework density, low porosity and small specific surface area of natural zeolite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

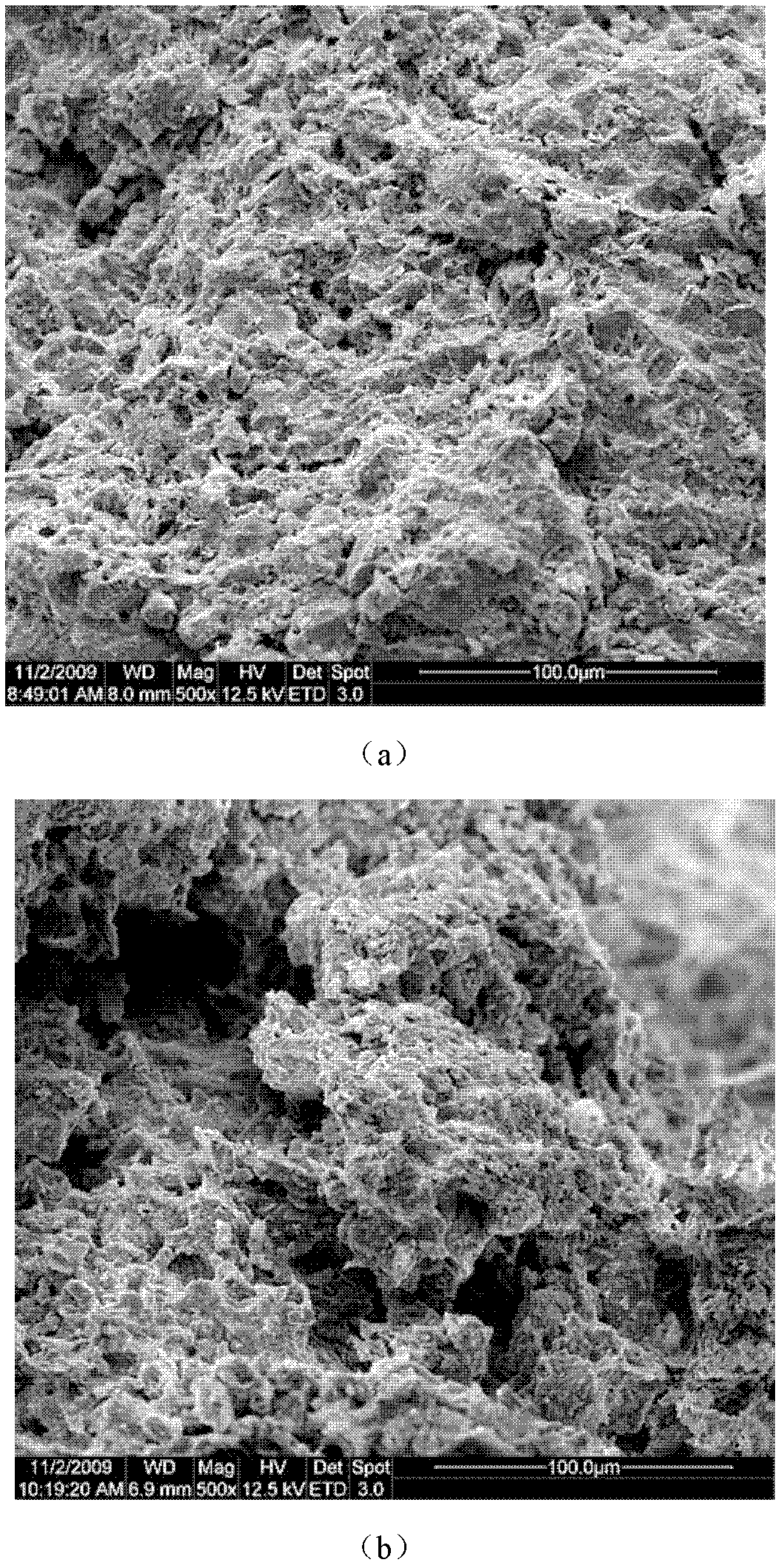

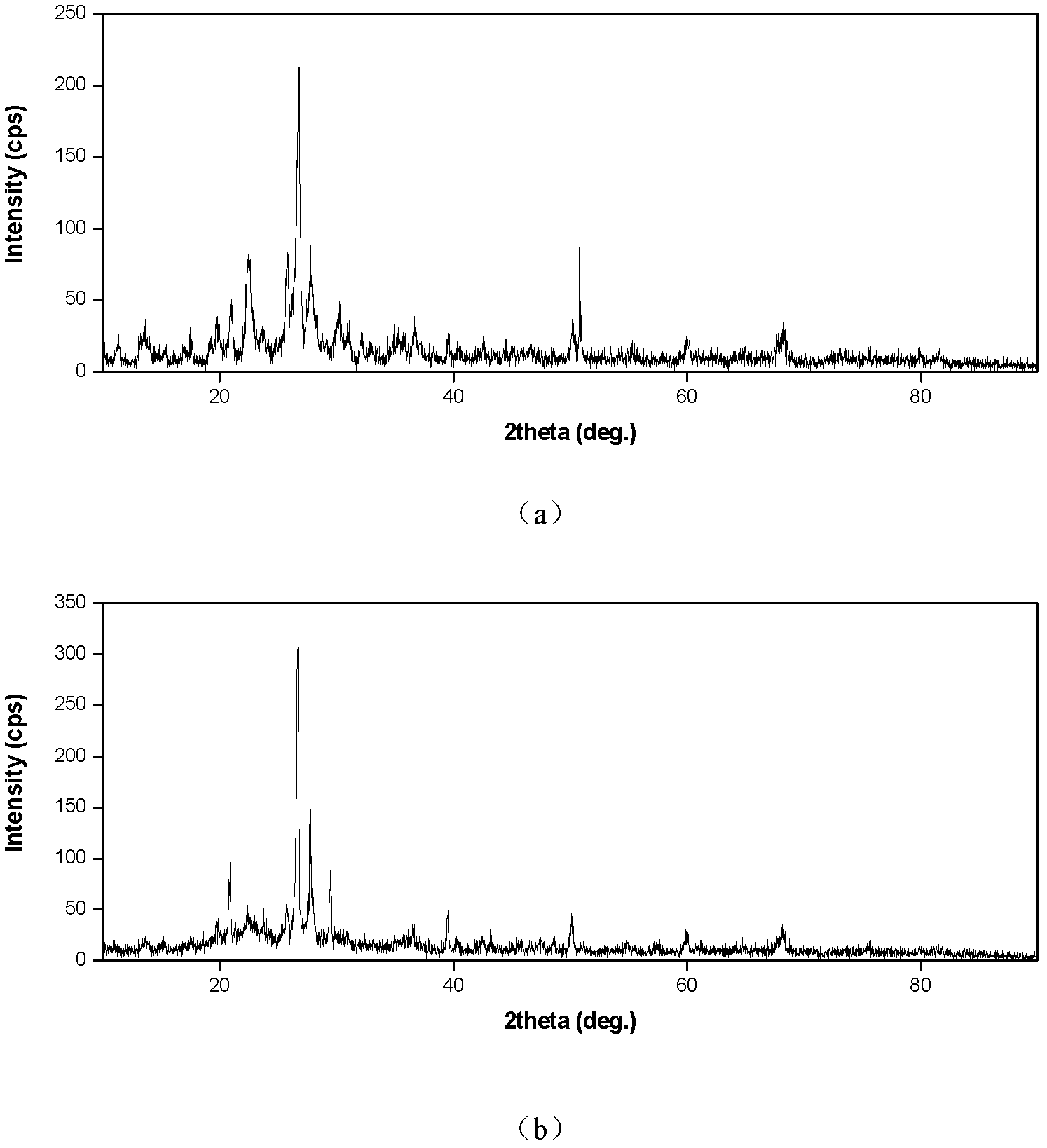

Image

Examples

Embodiment 1

[0035] According to the following proportions and methods, the modified zeolite filler BMZ-1 provided by the invention is prepared:

[0036] Natural zeolite particles with a particle size of 0.5-2mm, that is, zeolite sand, are composed of 60 parts by weight of zeolite powder with a fineness of 200-400 mesh, 10 parts by weight of starch with a fineness of 50-150 mesh, and coal with a fineness of 60-120 mesh. The zeolite powder mixture composed of 5 parts by weight of powder and 25 parts by weight of white Portland cement is placed in the mixer and mixed with a volume ratio of 1:1. Concentration is 10%, the aqueous solution of carboxymethyl cellulose that weight-average molecular weight is 19900) mixes with the ratio of accounting for 15% of zeolite sand and zeolite powder mixture total volume, stirs to obtain mixed matrix, this mixed matrix is put into particle Extruded by a granulator, dried at 105°C for 1 hour, and then put into a baking furnace for sintering at 650°C for 2...

Embodiment 2

[0079] Example 2, Application of Modified Zeolite Filler BMZ-1 in High Nitrogen Wastewater Treatment

[0080] 1. Adsorption-degradation test in MSM liquid medium

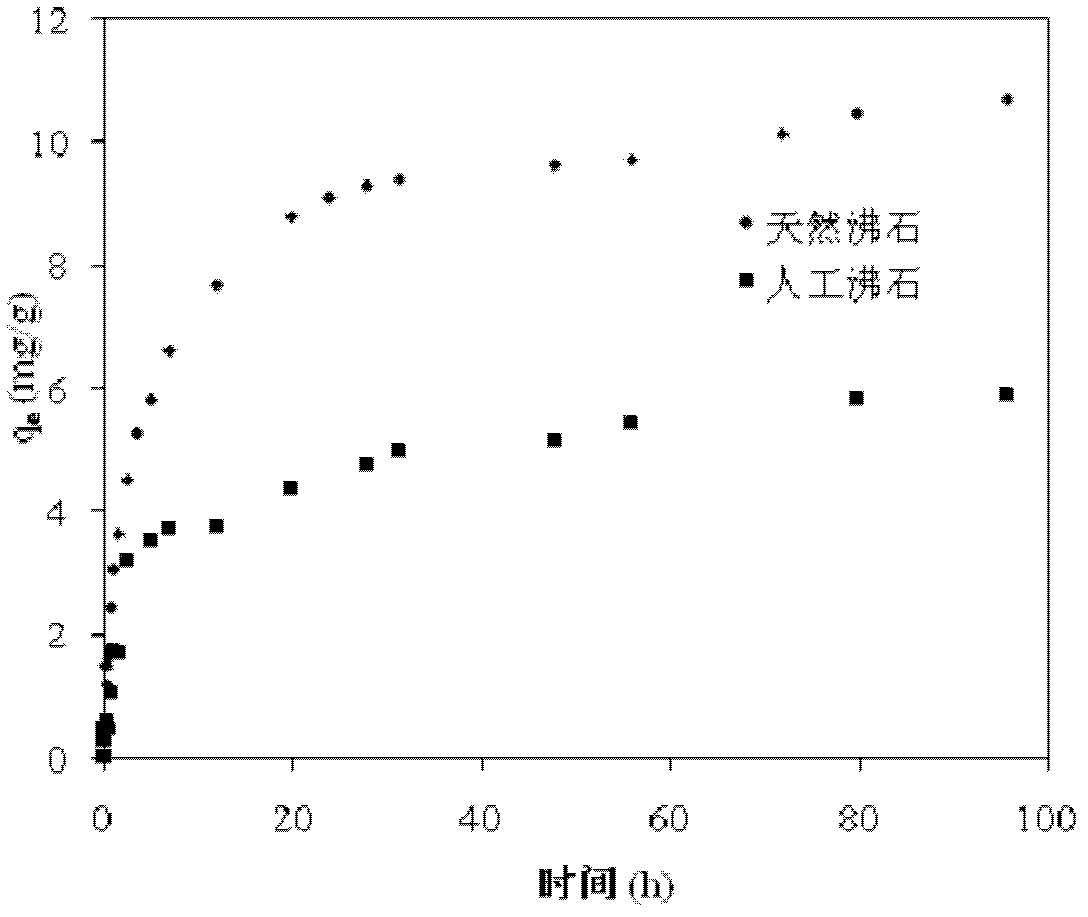

[0081] Pyridine and quinoline are two typical toxic and harmful nitrogen-heterocyclic aromatic compounds, and it is difficult for ordinary microorganisms to degrade these two pollutants. The present invention designs a group of adsorption-degradation experiments in which zeolite is added to a simple degradation system to investigate the control of the modified zeolite to the concentration of ammonia nitrogen.

[0082] In the MSM liquid medium of adding high-efficiency pyridine-degrading strain Paracoccus sp.BW001, preservation number (EU192073) and quinoline-degrading strain Pseudomonas sp.BW003, preservation number (EU371554), the natural zeolite and modified zeolite BMZ-1 were paired. Adsorption-degradation test of ammonia nitrogen, pyridine and quinoline. It was found that the presence of zeolite did not interf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com