Azoxystrobin-folpet compounded suspension agent and preparation method thereof

A technique of azoxystrobin and folpet, which is applied in the field of suspension preparation technology, can solve the problems of high cost of use, harm to human health, environmental pollution, etc., and achieve the effects of less dosage, less environmental pollution, and low cost of prevention and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

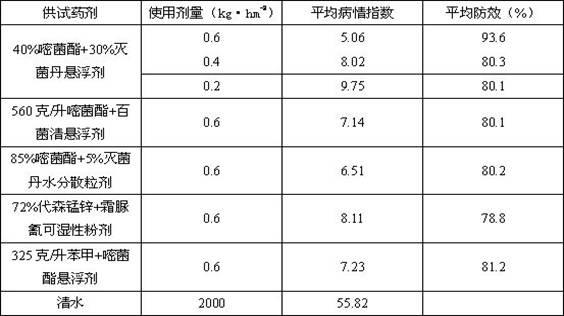

Image

Examples

Embodiment 1

[0030] Weigh 60% of azoxystrobin technical drug, 15% of sterile elixirs, wetting and dispersing agent YUS-SC3 3%, dispersing agent YUS-TXC 2%, antifreeze ethylene glycol 3%, thickening agent xanthan gum 0.2 %, adsorbent ultrafine white carbon black 0.5%, pH adjuster glacial acetic acid 0.2%, organosiloxane defoamer 0.5%, preservative sodium benzoate 0.1%, the balance is water, except for the thickener xanthan gum The external components are mixed with water to 95%, mixed and placed in a sand mill to grind, 4 hours later, grind to 3-5μm to obtain a preliminary shaped suspension product, and then mix the thickener xanthan gum with water To 5%, and add it to the initial product of the suspension, stir it with a mixer at a speed of 800 rpm for 3 hours to obtain the final product of the suspension composed of 60% azoxystrobin and 15% sanitizer. After testing, the content of azoxystrobin is 60%, the floatation rate of azoxystrobin is 98%, the content of azoxystrobin is 15.6%, the sus...

Embodiment 2

[0032] Weigh 55% of azoxystrobin technical, 20% of sterilized elixirs, wetting and dispersing agent YUS-SC3 4%, dispersing agent D-425 3%, antifreeze glycerin 4%, thickening agent magnesium aluminum silicate 0.3% , Superfine diatomaceous earth adsorbent 0.5%, pH adjuster citric acid 0.3%, organosiloxane defoamer 0.8%, preservative sodium benzoate 0.1%, the balance is water, except for the thickener magnesium aluminum silicate The external components are mixed with water to 95%, mixed and placed in a sand mill to grind, 4 hours later, grind to 3-5μm to obtain a preliminary shaped suspension product, and then mix the thickener with water to 5% , And added to the initial product of the suspension, after 3 hours of stirring with a mixer at a speed of 800 revolutions / min, the final product of the suspension composed of 55% azoxystrobin and 20% Sanitizer can be obtained. After testing, the content of azoxystrobin is 55.2%, the floating rate of azoxystrobin is 90%, the content of azox...

Embodiment 3

[0034] Weigh 50% of azoxystrobin original drug, 25% of sterile elixirs, 3.5% wetting and dispersing agent Tensiofix 35300, dispersant NNO 2.5%, antifreeze 3.5% sodium chloride, thickening agent carboxymethyl cellulose 0.25% , Adsorbent ultra-fine clay 0.65%, pH adjuster sorbic acid 0.25%, organosiloxane defoamer 0.5%, preservative sodium benzoate 0.1%, the balance is water, except for the thickener carboxymethyl cellulose Mix the components of the mixture with water to 95%, mix and grind in a sand mill. After 4 hours, grind to 3-5μm to obtain a preliminary formed suspension product. Then mix the thickener with water to 5%. It is added to the initial product of the suspension, and the final product of the suspension composed of 50% azoxystrobin and 25% azoxystrobin and 25% sanitizer is obtained after stirring with a mixer at a speed of 800 revolutions per minute for 3 hours. After testing, the content of azoxystrobin is 50%, the floatation rate of azoxystrobin is 91%, the conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com