Colored UV-light-curable paint

A technology of curing coatings and ultraviolet light, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high price and difficult to widely use, and achieve the effect of high curing activity, wide applicability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

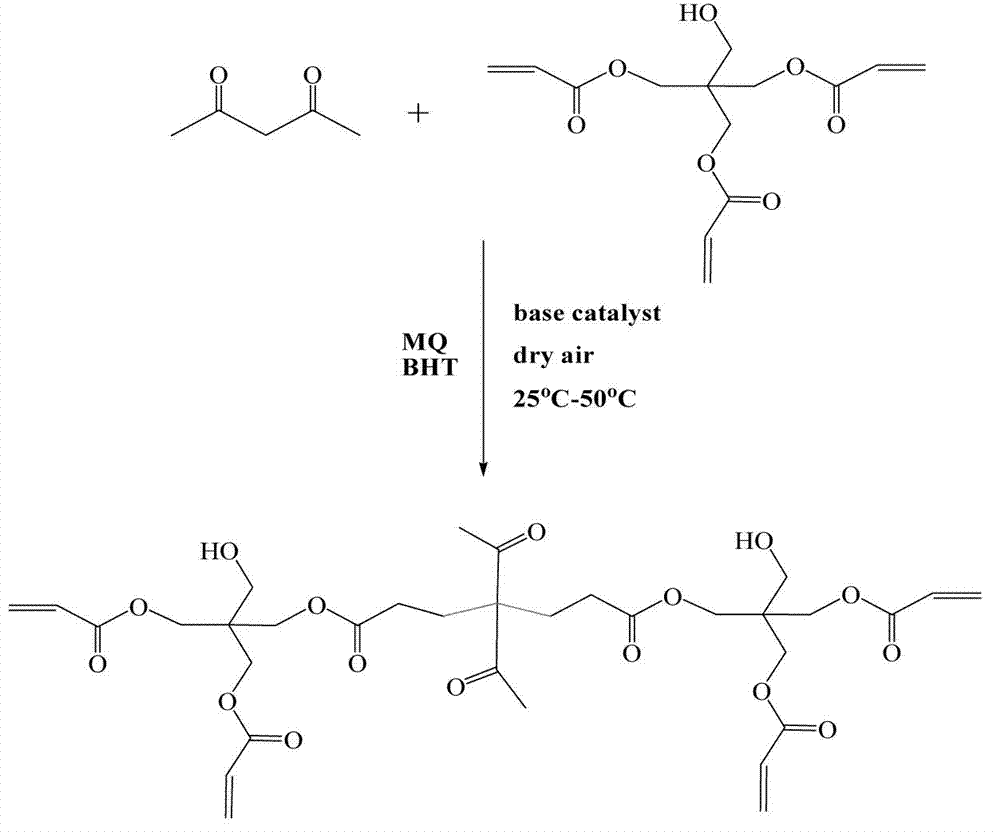

[0035] Example 1 (Preparation of self-initiating resin HV-301B)

[0036] Into a 5000ml four-necked flask equipped with a condenser tube, a thermometer, an air duct, and a mechanical stirrer, pass dry air into it, start the stirrer, add 2661.6g of pentaerythritol triacrylate after 10 minutes, and dissolve 0.7g of it with 20.0g of butyl acetate p-methoxyphenol (MQ), 1.4g 2,6-di-tert-butyl-p-cresol (BHT), add the above solution into the reaction kettle under stirring condition, weigh 35.6g of 1,8-diazabicyclo [5.4.0] Undec-7-ene (DBU), dropwise added to the reaction kettle under stirring conditions, slowly warming up to 45°C; weigh 1000.0g acetylacetone, and use a constant pressure dropping funnel for 150-180min After the internal dropwise addition, wash the funnel with 30.0g of butyl acetate solvent, keep it warm at 45-55°C for 4h, add 20.0g of acrylic acid, and discharge, obtained from the initiator resin HV-301B, the reaction equation of the resin is shown in figure 1 , the...

Embodiment 2

[0037] Example 2 (Preparation of transparent red paste)

[0038] The preparation method of transparent red paste comprises the following steps:

[0039] 1) Mix 13.56g xylene and 13.56g butyl acetate to obtain a mixed solvent;

[0040] 2) Pre-disperse 34.84g of self-initiating resin (B-12, HV-301B of Guangzhou Boxing with a mass ratio of 3:1), add 1.31g of dispersant (EFKA 4010) and 13.02g of mixed solvent in sequence, and add it under stirring 4.47g transparent red powder (DIC, model: R-185), mixed well to obtain a mixture;

[0041]3) Grind the mixture at 35-40°C until the fineness is less than 5 μm, filter the material with a 5 μm filter bag, add 14.1 g of mixed solvent, and stir evenly to obtain a transparent red slurry.

[0042] The transparent red paste used in the following examples all adopts the transparent red paste prepared in this embodiment.

Embodiment 3

[0043] Example 3 (Colored UV-curable coatings)

[0044] A colored ultraviolet light curing coating, the coating contains the following components by weight:

[0045] 38 parts of urethane acrylate (UV-7605B), 7.1 parts of urethane acrylate (UV1000), 30 parts of self-initiating resin (HV-301B), 3 parts of trimethylolpropane triacrylate, 5 parts of transparent red paste, FMT 2.0 Parts, 0.5 part of 1-hydroxycyclohexyl phenyl ketone (Irgacure 184), mixed solvent (ratio by weight: 20% toluene, 40% ethyl acetate, 10% propylene glycol butyl ether, 20% cyclohexane, 10% ethyl ketone %) 20.2 parts, leveling agent (BYK333) 0.6 parts, leveling agent (BYK306) 0.2 parts, leveling agent (EFKA 3777) 0.2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com