Anti-depression slow-release capsule

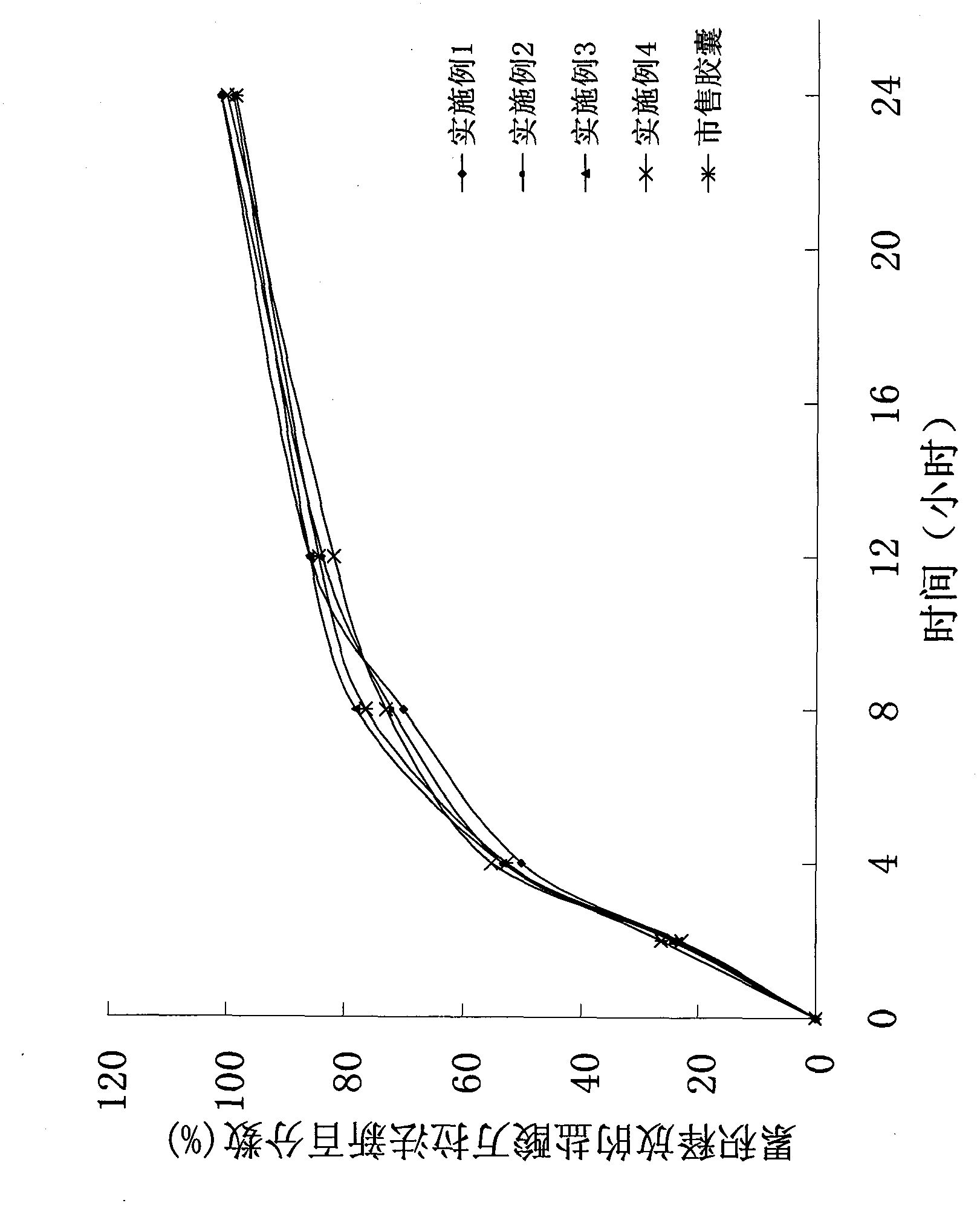

A slow-release capsule and antidepressant technology, which can be applied to drug combinations, nervous system diseases, organic active ingredients, etc., can solve the problems of large fluctuation of blood drug concentration, low technical content, hidden safety hazards, etc., and achieves reasonable structure and simple preparation process. , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

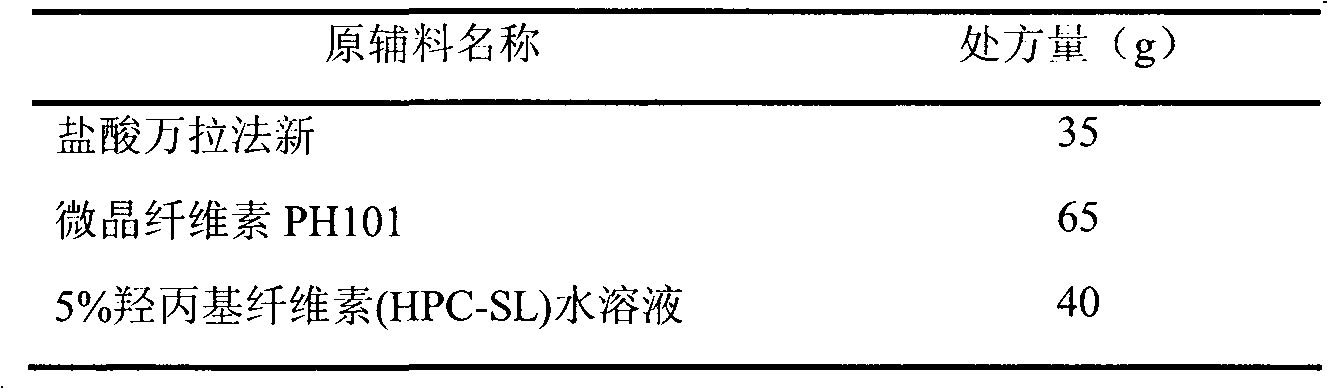

[0028] Prescription with pill core:

[0029]

[0030] Pill core preparation method:

[0031] 1. Mix venlafaxine hydrochloride and microcrystalline cellulose PH101 evenly

[0032] 2. Make soft materials with 5% hydroxypropyl cellulose (HPC-SL) aqueous solution

[0033] 3. Extrude in an extruder (screen diameter: 1mm, extrusion rate: 25rpm)

[0034] 4. The extruded material is rounded in a rounding machine (rounding speed: 1000rpm, extrusion time: 5min)

[0035] 5. Dry in an oven at 40°C for 2 hours

[0036] 6. Pass through a 12-mesh sieve to remove large pills, and pass through a 20-mesh sieve to remove small pills

[0037] Isolation Layer Prescription:

[0038]

[0039] Preparation method of the isolation layer solution: add hydroxypropyl cellulose (HPC-SL) into water to dissolve completely, and stir magnetically to obtain the product.

[0040] Isolation layer coating operation process: using fluidized bed bottom spray coating

[0041] Spray speed: 1~2ml / min

[004...

Embodiment 2

[0057] Prescription with pill core:

[0058]

[0059] Pill core preparation method:

[0060] 1. Mix venlafaxine hydrochloride and microcrystalline cellulose PH101 evenly

[0061] 2. Make soft materials with 5% hypromellose (HPMC E6) aqueous solution

[0062] 3. Extrude in an extruder (screen diameter: 1mm, extrusion rate: 25rpm)

[0063] 4. The extruded material is rounded in a rounding machine (rounding speed: 1000rpm, extrusion time: 5min)

[0064] 5. Dry in an oven at 40°C for 2 hours

[0065] 6. Pass through a 12-mesh sieve to remove large pills, and pass through a 20-mesh sieve to remove small pills

[0066] Isolation Layer Prescription:

[0067]

[0068] Preparation method of the isolation layer solution: add hypromellose and propylene glycol into water to dissolve completely, stir magnetically, and obtain.

[0069] Isolation layer coating operation process: using fluidized bed bottom spray coating

[0070] Spray speed: 1~2ml / min

[0071] Spray pressure: 0....

Embodiment 3

[0086] Prescription with pill core:

[0087]

[0088] Pill core preparation method:

[0089] 1. Mix venlafaxine hydrochloride and microcrystalline cellulose PH101 evenly

[0090] 2. Make soft material with 5% kollicoatIR aqueous solution

[0091] 3. Extrude in an extruder (screen diameter: 1mm, extrusion rate: 25rpm)

[0092] 4. The extruded material is rounded in a rounding machine (rounding speed: 1000rpm, extrusion time: 5min)

[0093] 5. Dry in an oven at 40°C for 2 hours

[0094] 6. Pass through a 12-mesh sieve to remove large pills, and pass through a 20-mesh sieve to remove small pills

[0095] Isolation Layer Prescription:

[0096]

[0097] Preparation method of isolation layer solution: add kollicoatIR to water to dissolve completely, stir magnetically, and obtain.

[0098] Isolation layer coating operation process: using fluidized bed bottom spray coating

[0099] Spray speed: 1~2ml / min

[0100] Spray pressure: 0.75bar

[0101] Air intake: 440L / min

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com