Ultrathin metal membrane terahertz absorbed layer and preparation method thereof

An ultra-thin metal, terahertz technology, which is used in the field of terahertz detection and imaging, and can solve problems such as the preparation of absorption layers that cannot be used in terahertz detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

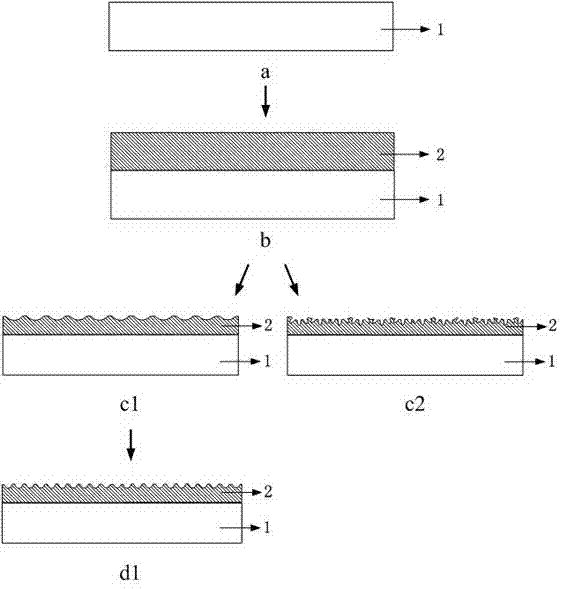

Method used

Image

Examples

Embodiment 1

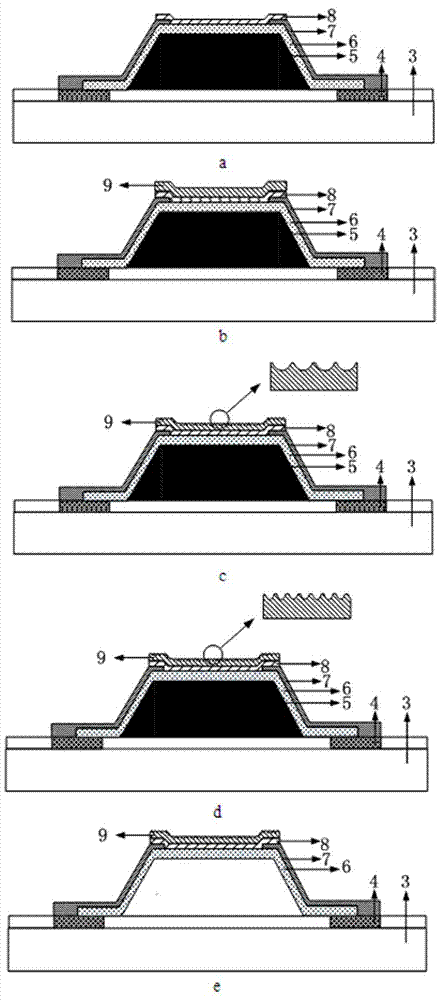

[0055] An ultra-thin metal film terahertz absorption layer, which is prepared on the top layer of the detection unit of the terahertz microarray detector, such as figure 2 shown.

[0056] The detection unit of the terahertz microarray detector such as figure 2 -a shown. The array unit is prepared on the silicon wafer with the underlying readout circuit 3, wherein the readout circuit has an interface 4 with the subsequent MEMS device, and then grows a sacrificial layer 5, a supporting layer 6, metal electrodes and leads 7, and a sensitive film 8 etc. and graph them separately. The sacrificial layer material can be silicon oxide film or photosensitive polyimide (PSPI) material; the support layer material is composed of silicon nitride, silicon oxide or multi-layer composite film; the metal electrode is aluminum, titanium, nickel-chromium alloy, etc. ; Sensitive films are vanadium oxide films, amorphous silicon films, etc.

[0057] The aluminum metal thin film 9 was prepare...

Embodiment 2

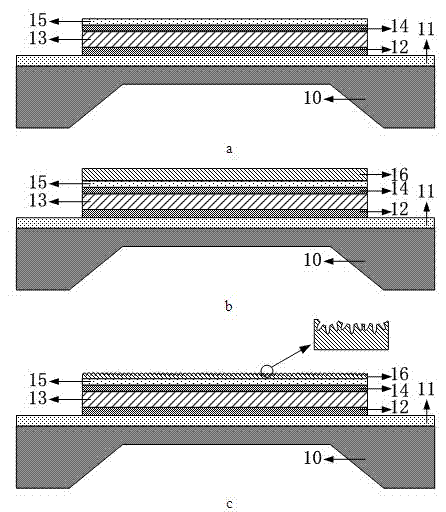

[0062] An ultra-thin metal film terahertz absorbing layer, which is prepared on the top layer of the pyroelectric terahertz detection unit, such as image 3 shown.

[0063] Pyroelectric terahertz detection unit such as image 3 -a shown. The preparation process of the detection unit is: remove a part of the silicon substrate 10 by chemical etching, and then prepare the silicon dioxide insulating layer 11, the lower electrode 12, the lithium tantalate pyroelectric film 13, the upper electrode 14 and the silicon nitride dielectric layer 15 .

[0064] Clean the top surface of the detection unit to remove surface contamination, and bake the substrate at 200°C to remove surface moisture and enhance the adhesion of the dielectric film.

[0065] The NiCr alloy thin film 16 was prepared by magnetron sputtering. Adjust the process parameters to control the film thickness to 100nm, such as image 3 -b shown.

[0066] The wet chemical etching method is used to etch and thin the NiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com