Charging-discharging module based on giant permittivity ceramic capacitor and preparation method of charging-discharging module

A technology of ceramic capacitors and charging and discharging modules, applied in the field of capacitors, can solve problems such as prolonging the working time of electrical equipment, and achieve the effects of fast charging and discharging rate, no chemical pollution, and fast charging and discharging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

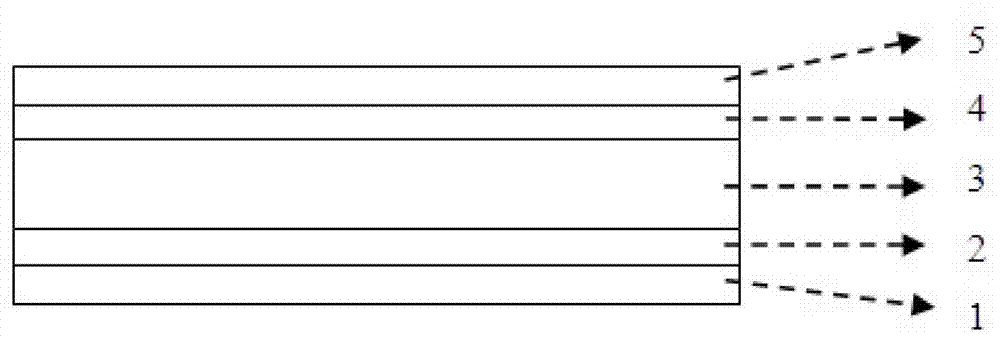

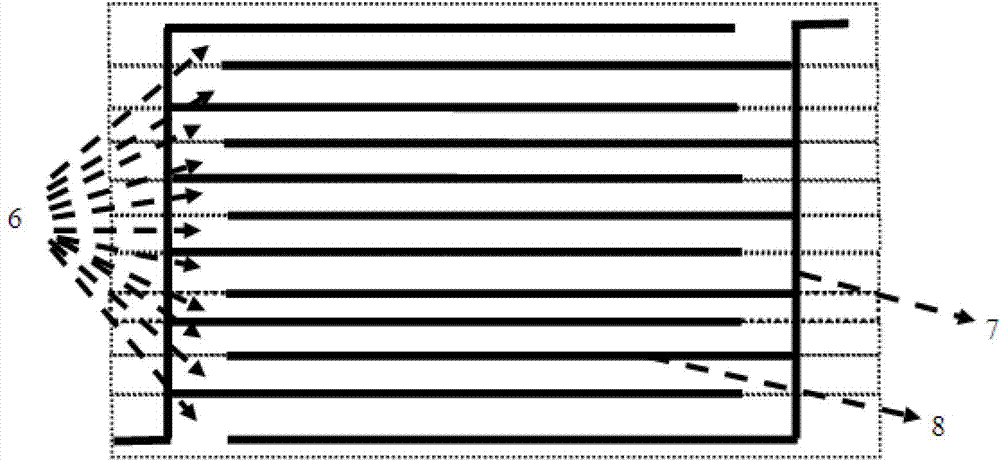

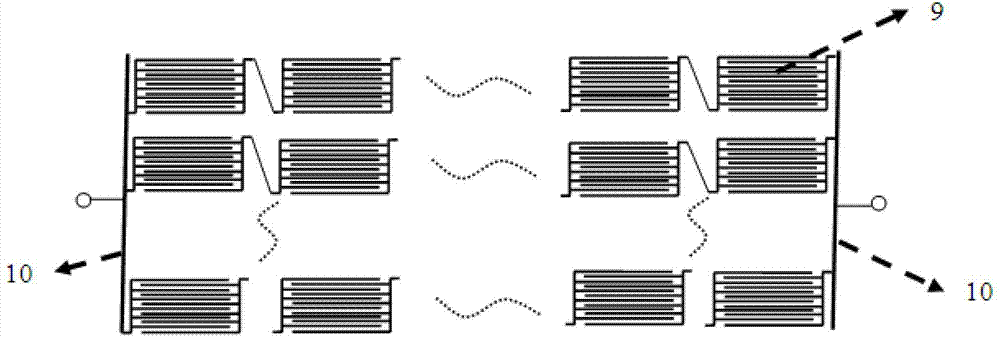

[0039] In this embodiment, a large permittivity ceramic capacitor monomer is made with copper calcium titanate ceramics as the intermediate dielectric layer 3, and the aluminum oxide nano-insulation layer is the lower breakdown-resistant layer 2 and the upper breakdown-resistant layer 4. To form a charging and discharging module of a giant permittivity ceramic capacitor, the specific steps are:

[0040] 1) Preparation of copper calcium titanate ceramics by solid state reaction method. Mix calcium carbonate, copper oxide and titanium oxide in a molar ratio of 1:3:4, and pre-fire the mixed powder at 850°C for 5 hours to form copper calcium titanate powder. Copper calcium titanate powder, 6wt% Polyvinyl alcohol aqueous solution, glycerin and defoaming agent are mixed evenly at a mass ratio of 40:30:5:0.2, and a green sheet with a thickness of 1 μm is prepared by casting technology, and the green sheet is sintered in an electric furnace at 1060 ° C for 10 hours to obtain copper ti...

Embodiment 2

[0046] In this embodiment, a large permittivity ceramic capacitor monomer is made with copper calcium titanate ceramics as the intermediate dielectric layer 3, and the titanium oxide nano-insulation layer as the lower breakdown-resistant layer 2 and the upper breakdown-resistant layer 4. To form a charging and discharging module of a giant permittivity ceramic capacitor, the specific steps are:

[0047] 1) Preparation of copper calcium titanate ceramics by solid state reaction method. Mix calcium carbonate, copper chloride and titanium oxide in a molar ratio of 1:3:4, and pre-fire the mixed powder at 950°C for 2 hours to form copper calcium titanate powder. Copper calcium titanate powder, 6wt % polyvinyl alcohol aqueous solution, glycerol and antifoaming agent were mixed evenly at a mass ratio of 50:45:5:0.2, and a green sheet with a thickness of 100 μm was prepared by tape casting technology, and the green sheet was sintered in an electric furnace at 1080 ° C for 5 hours to o...

Embodiment 3

[0053] In this embodiment, a large permittivity ceramic capacitor monomer is made with copper calcium titanate ceramics as the intermediate dielectric layer 3, and the silicon oxide nano-insulation layer as the lower breakdown-resistant layer 2 and the upper breakdown-resistant layer 4. To form a charging and discharging module of a giant permittivity ceramic capacitor, the specific steps are:

[0054] 1) Preparation of copper calcium titanate ceramics by solid state reaction method. Mix calcium nitrate, copper oxide and titanium oxide in a molar ratio of 1:3:4, and pre-fire the mixed powder at 900°C for 3 hours to form copper calcium titanate powder. Copper calcium titanate powder, 6wt% Polyvinyl alcohol aqueous solution, glycerin and defoaming agent are mixed evenly at a mass ratio of 45:40:5:0.2, and a green sheet with a thickness of 2000 μm is prepared by casting technology, and the green sheet is sintered in an electric furnace at 1100 ° C for 2 hours to obtain copper tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com