Method for improving yield of arginine of corynebacterium crenatum by synthesis way through knocking out proline

A technology of Corynebacterium blunt tooth, proline, applied in the field of biology, can solve the problem that the genetic background is in a blank state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

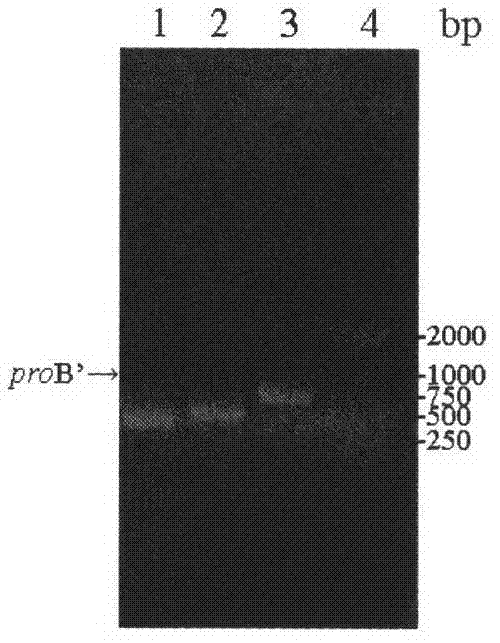

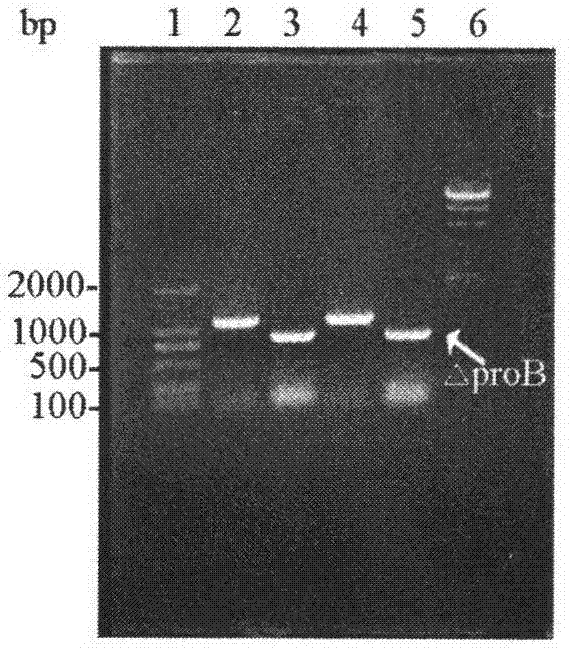

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Detection of glutamic acid kinase enzyme activity in the recombinant corynebacterium bacillus

[0024] The proB gene-deleted transformants verified above were randomly selected and cultured in the seed medium to the logarithmic growth phase, and the bacterial cells were collected and ultrasonically disrupted to measure the activity of intracellular glutamate kinase: with L-glutamic acid as the substrate, Add 50mM L-glutamic acid, 10mM ATP, 20mM MgCl in 0.25mL system with pH 7.0 2 , 100mM hydroxylammonium hydrochloride, 50mM Tris, add 200μL of crude enzyme solution, mix thoroughly, place at 37°C, and react for 30min. FeCl with trichloroacetic acid added 3 1 mL of the reaction termination solution was centrifuged at 3,500 g at a low speed, and the supernatant was taken to measure the absorbance of γ-glutamic acid hydroxamic acid at 535 nm. 1 U is defined as the amount of enzyme required to generate 1 μmol of hydroxamate per minute. Compared with the contr...

Embodiment 2

[0025] Example 2: Shake flask fermentation of recombinant Corynebacterium blunt-toothed ΔproB transformants to produce L-arginine

[0026] Seed medium (g / L): glucose 30, corn steep liquor 20, urea 1.5, KH 2 PO 4 1, (NH 4 ) 2 SO 4 20, MgSO 4 ·7H 2 O 0.5; pH 7.0-7.2, filling volume 30mL / 250mL, sterilize at 121°C for 20min.

[0027] Fermentation medium (g / L): glucose 150 (divided), corn steep liquor 40, biotin 8×10 -5 , L-histidine 5×10 -4 , MnSO 4 ·H 2 O 0.02, (NH 4 ) 2 SO 4 20, MgSO 4 ·7H 2 O 0.5, KH 2 PO 4 1.5, FeSO 4 ·7H 2 O 0.02, CaCO 3 30 (minus sterilization). The pH is 7.0-7.2, the filling volume is 25mL / 250mL, and it is sterilized at 121°C for 10 minutes.

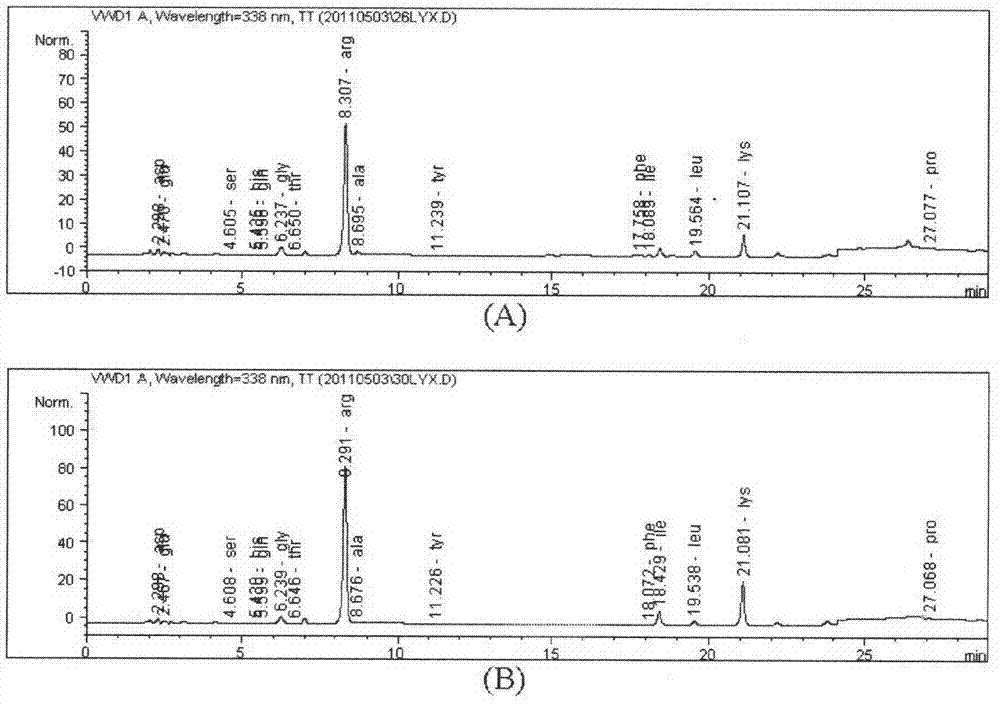

[0028] The above-mentioned recombinant bacteria Corynebacterium blunt toothed SYPA 5-5ΔproB, which has been verified by enzyme activity, was subjected to a shake flask fermentation experiment, and a ring of Coryne bacillus blunt toothed bacteria (control bacteria and recombinant bacteria) was pick...

Embodiment 3

[0029] Example 3: Recombinant Corynebacterium blunt-toothed ΔproB transformant fermented in a 5L fermenter to produce acid

[0030] Seed medium (g / L): glucose 30, corn steep liquor 20, urea 1.5, KH 2 PO 4 1, (NH 4 ) 2 SO4 20, MgSO 4 ·7H 2 O 0.5; pH 7.0-7.2, filling volume 30mL / 250mL, sterilize at 121°C for 20min.

[0031] Fermentation medium (g / L): glucose 150 (divided), corn steep liquor 40, biotin 8×10 -5 , L-histidine 5×10 -4 , MnSO 4 ·H 2 O 0.02, (NH 4 ) 2 SO 4 20, MgSO 4 ·7H 2 O 0.5, KH 2 PO 4 1.5, FeSO 4 ·7H 2 O 0.02, CaCO 3 30 (minus sterilization). pH is 7.0~7.2, liquid volume is 25mL / 250mL, sterilized at 121℃ for 10min [93] .

[0032] Batch fermentation conditions in 5L self-controlled fermenter: liquid volume in 5L fermenter is 3L, inoculum size is 5%, 30℃, ventilation rate is 3L / min, ammonia water is added automatically to control pH at 6.8, factory fermentation of L-fine Special antifoaming agent for amino acid, automatic control of dissolved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com