Technology for preparing 3-phenyl-4-aminobutyric acid hydrochloride

A technology of aminobutyric acid hydrochloride and methyl nitrobutyrate, applied in the field of chemistry, can solve the problems of low overall yield of the target product, difficult operation, many reaction steps, etc., and achieves improved hydrogenation efficiency, simple and convenient control , the effect of good reaction rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

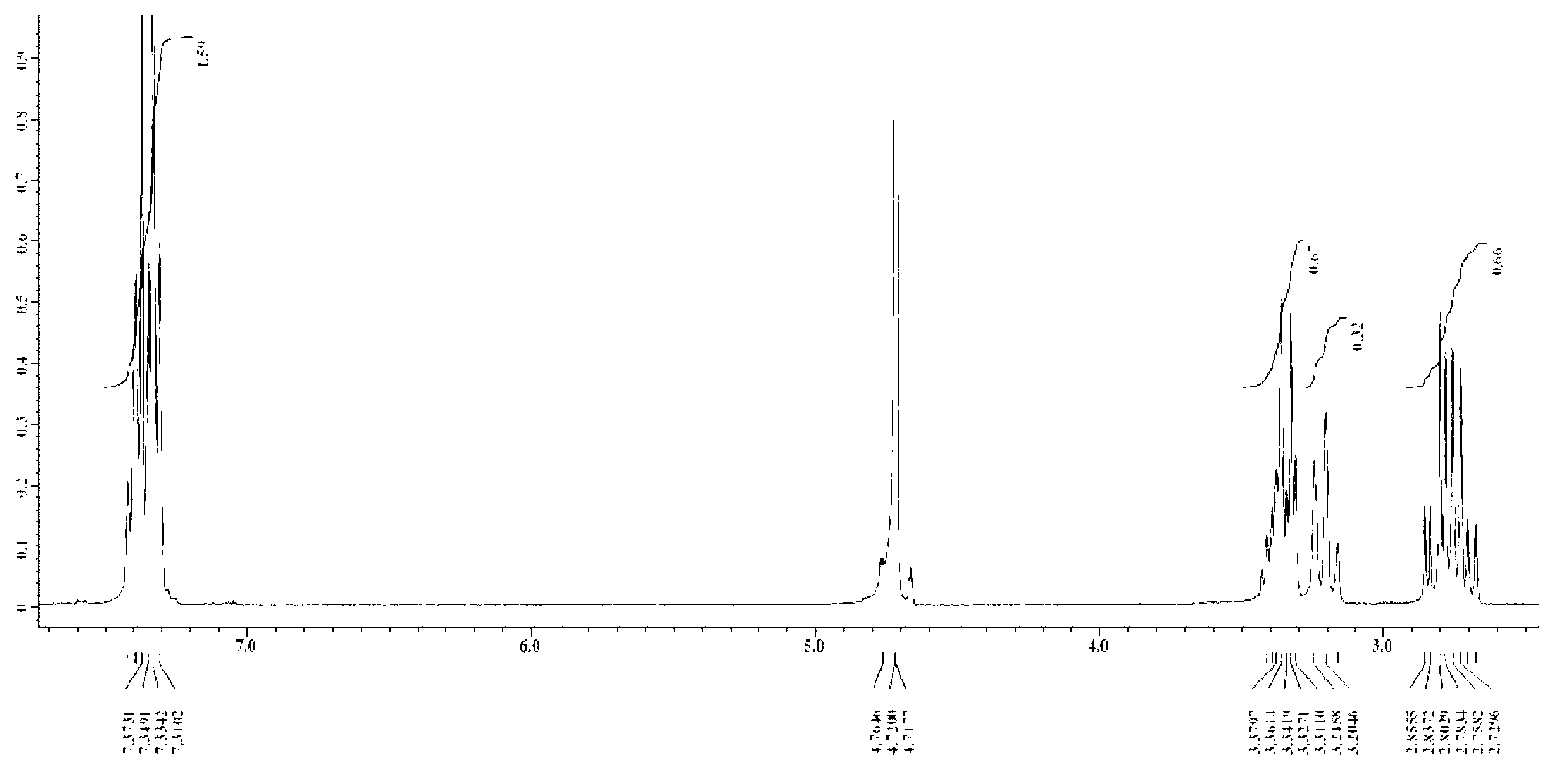

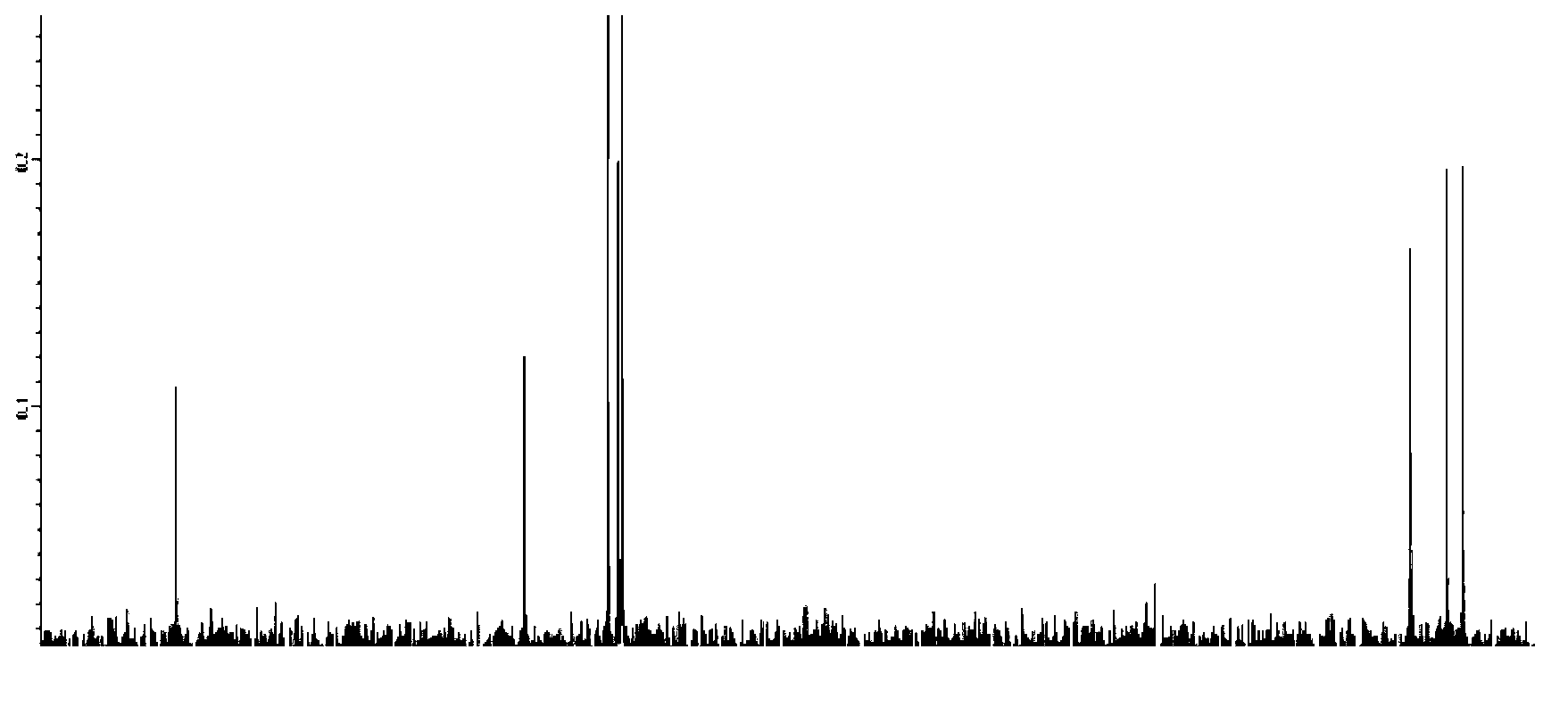

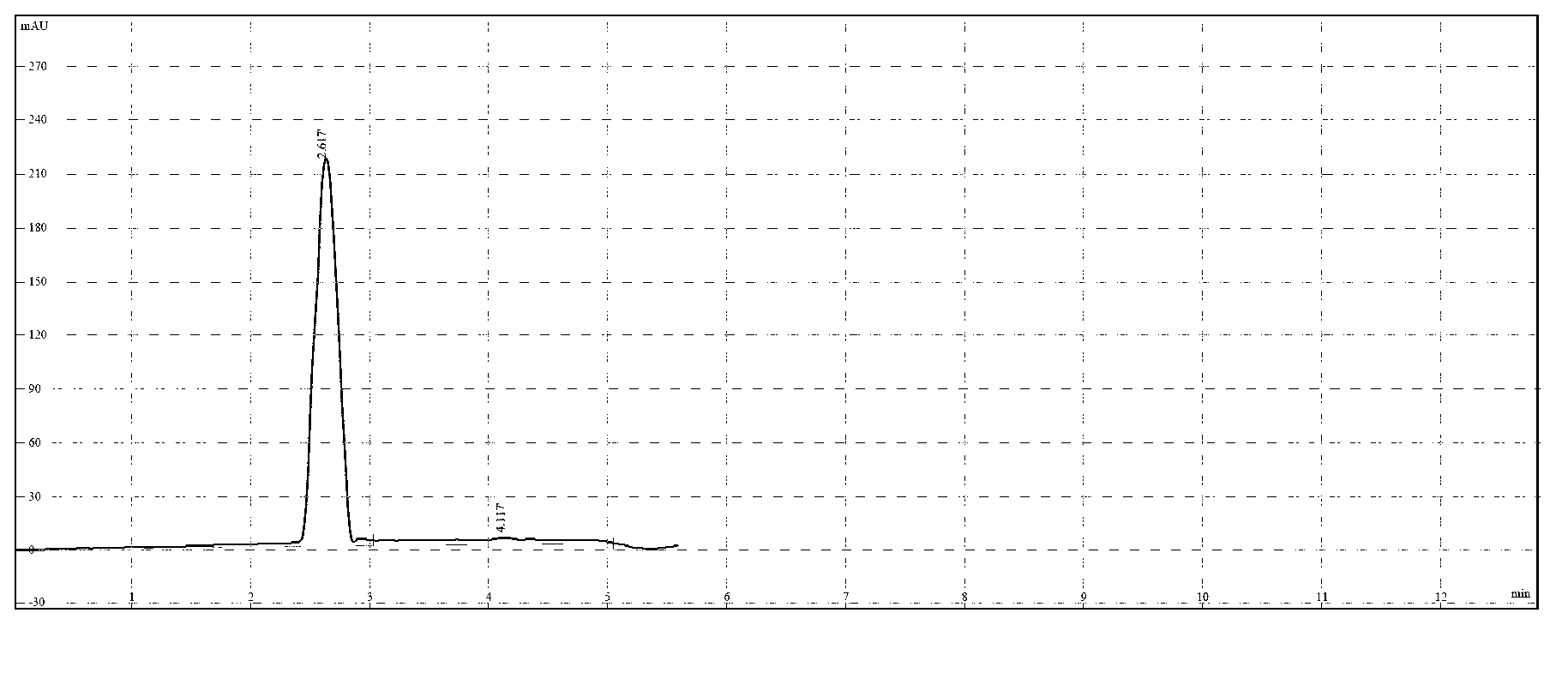

Image

Examples

Embodiment 1

[0035] Get 9.8g of methyl cinnamate, 40ml of nitromethane is placed in a 100ml three-necked flask, stir, heat up to 50°C, then add 1.5g of triethylamine and 0.5g of anhydrous MgCl , maintain 50°C for 10h , TLC detected that the reaction was complete.

[0036] Distill under reduced pressure to remove excess nitromethane, then transfer the solution with a small amount of ethyl acetate, wash with 5% hydrochloric acid for 3 times, then wash with water until neutral, and then wash with anhydrous MgSO 4 Dry to obtain 12.98g of 3-phenyl-4 nitrobutyric acid methyl ester, yield rate is 94.1%

[0037] Take 12.98g of methyl 3-phenyl-4-nitrobutyrate, add 200ml of ethanol, then add 0.13g of Raney nickel into the reaction system, stir, raise the temperature to 50°C, and inject hydrogen gas (just bubbling) to The reaction was monitored by TLC, and the reaction time was about 8h. After filtration, the resulting filtrate was distilled under reduced pressure to obtain 8.33 g of 3-phenylvalerola...

Embodiment 2

[0041] Get 49g methyl cinnamate, 200ml nitromethane is placed in the three-necked bottle of 500ml, stir, be warming up to 50 ℃, then add 7.5g triethylamine and 2.5g anhydrous MgCl , maintain 50 ℃ of reaction 10h, TLC detects that the reaction is complete.

[0042] Distill under reduced pressure to remove excess nitromethane, then transfer the solution with a small amount of ethyl acetate, wash with 5% hydrochloric acid for 3 times, then wash with water until neutral, and then wash with anhydrous MgSO 4 Dry to obtain 3-phenyl-4 nitrobutyric acid methyl ester 64.9g, productive rate is 94.1%

[0043] Take 64.9g of methyl 3-phenyl-4-nitrobutyrate, add 1000ml of ethanol, then add 0.65g of Raney nickel into the reaction system, stir, raise the temperature to 50°C, and inject hydrogen gas (just bubbling), to The reaction was monitored by TLC, and the reaction time was about 12 h. After filtration, the resulting filtrate was distilled under reduced pressure to obtain 41.6 g of 3-phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com