Resin composition for CRTS (China Rail Traffic Summit) I type slab ballastless track and preparation method of resin composition

A resin composition and composition technology, applied in the field of filled resin compositions, can solve the problems of long required strength, long and limited maintenance time, etc., achieve the restoration of adjustment ability, solve the failure of fasteners, and reduce maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

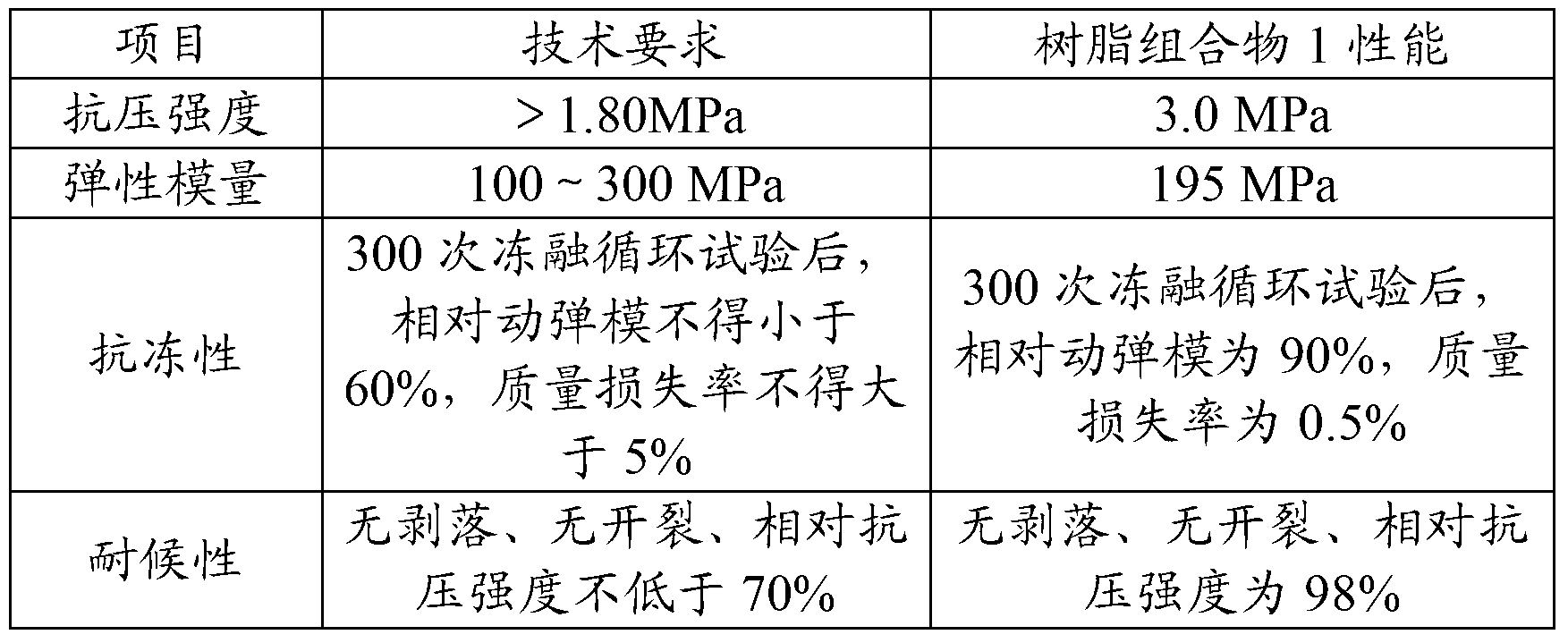

[0064] Example 1 Preparation of Resin Polymer

[0065] 35kg vinyl resin polymer (including 20kg polymethyl methacrylate (PMMA resin) and 15kg acrylonitrile-butadiene-styrene copolymer (ABS resin)), 15kg reactive diluent ethyl methacrylate, 40kg Add non-rubber tougheners (including 30kg butyl methacrylate and 10kg diethylene glycol benzoate) into the reactor with a disperser, and stir until the pellets are completely dissolved. The temperature of the reactor is 40°C. The stirring speed of the disperser is 1400 rpm. Then lower the temperature of the reactor to room temperature, and add 40kg of self-made polyurethane-modified acrylate polymer (formed by polymerization of toluene diisocyanate (TDI) and hydroxyethyl acrylate) at the stirring speed of the disperser at 1800 rpm ), 25kg modified bisphenol A epoxy modified acrylic resin (Taiwan Double Bond Chemical Co., Ltd.), 18kg rubber toughening agent liquid nitrile rubber, 6kg catalyst cobalt naphthenate, 2kg ultraviolet absorbe...

Embodiment 2

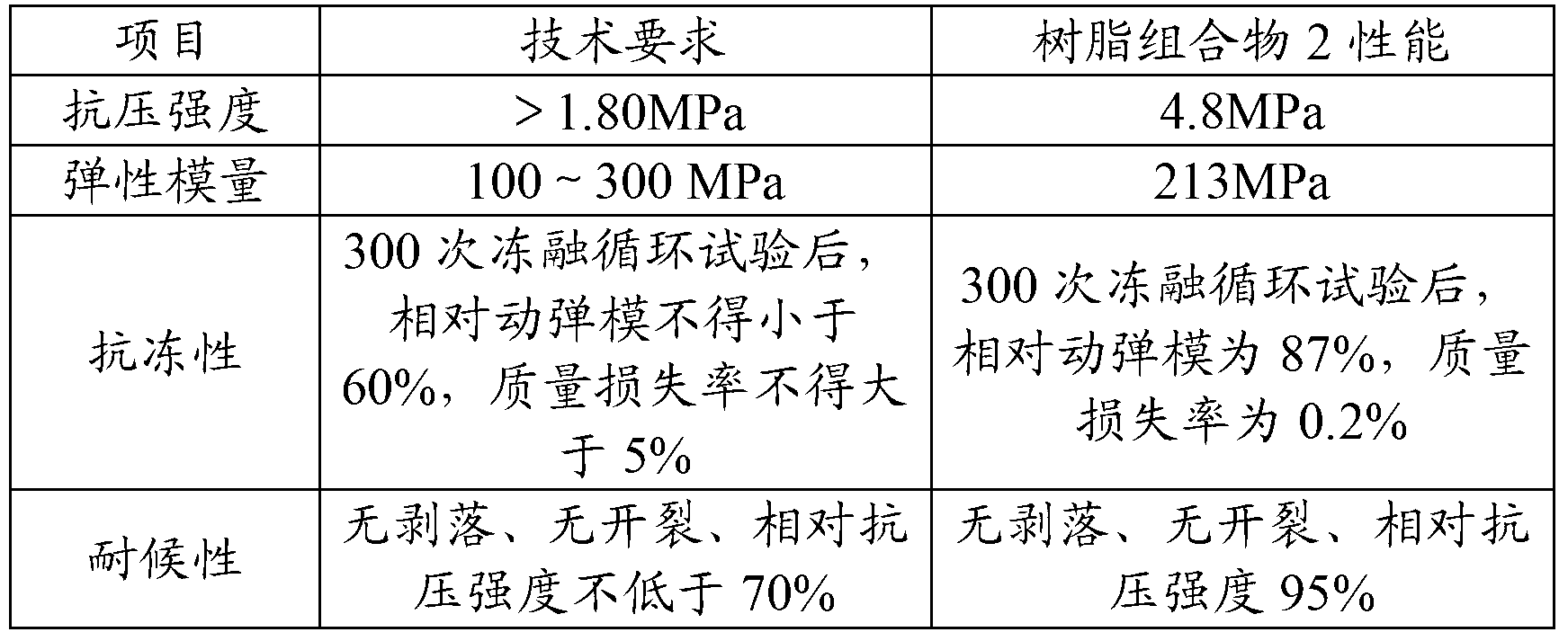

[0075] Example 2 Preparation of Resin Polymer

[0076]100kg vinyl resin composition (including 40kg acrylic resin homopolymer (Taiwan Double Bond Chemical Co., Ltd.), 40kg polyurethane modified acrylic resin (DuPont Company) and 20kg novolac epoxy acrylic resin (Jinan Yisheng), 8kg reactive dilution Methyl acrylate, 48kg non-rubber toughening agent (including 20kg 2-methylhexyl acrylate, 18kg octyl methacrylate and 10kg dibutyl phthalate), 20kg rubber toughening agent neoprene, 2.0kg Catalyst N,N-diethylaniline, 2kg UV absorber 2-(5-chloro-2H-benzotriazol-2-yl)-4,6-bis(1,1-dimethylethyl)phenol , 3kg light stabilizer 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, 3kg antioxidant triphenyl phosphite, 4kg coupling agent isopropyl three (dioctyl Pyrophosphate acyloxy) titanate and 10kg thixotropic agent gas-phase method white carbon black are added in the stainless steel reactor with disperser and stirred, wherein the temperature of reactor is 60 ℃, and the stirring speed of dispe...

Embodiment 3

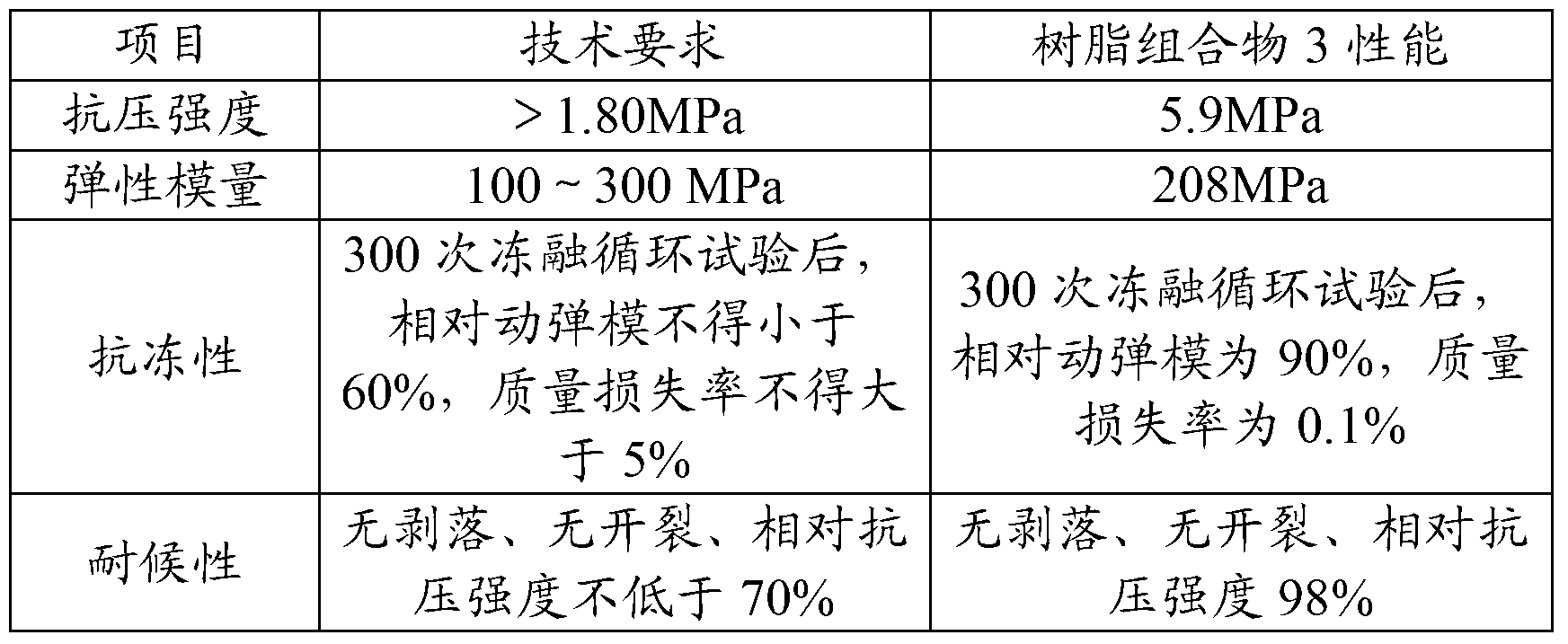

[0081] Example 3 Preparation of Resin Polymer

[0082] 70kg vinyl resin composition (including 30kg acrylic resin copolymer (BASF) and 40kg polyether modified acrylate polymer (BASF), 50kg non-rubber toughening agent (including 20kg butyl methacrylate, 10kg formazan octyl acrylate, 10kg 2-methylhexyl acrylate and 10kg diethylene glycol benzoate), 15kg rubber toughening agent neoprene, 5kg catalyst N,N-diethylaniline, 2.5kg ultraviolet absorber ( 2-hydroxy-4-methoxyphenyl) phenyl ketone, 4kg light stabilizer bis(1,2,2,6,6-pentamethyl-4-pyridyl) sebacate, 2.5kg antioxidant Add diphenylisodecyl phosphite, 2kg coupling agent isopropyl tris(dioctyl pyrophosphate acyloxy) titanate and 20kg thixotropic agent nano silicon dioxide into a stainless steel reaction kettle with a disperser and stirring, wherein the temperature of the reaction kettle is 60° C., the stirring speed of the disperser is 1000 rpm, and the stirring is carried out until uniform, and the A component is prepared....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com