Ultra Thin Film Field Effect Transistor Sensor and Its Application

A technology of transistors and sensors, which is applied in the field of ultra-thin film field effect transistor sensors, can solve problems such as unsatisfactory response or selectivity of devices, unfavorable large-scale preparation and application, and harsh technical means, and achieve excellent solution film-forming characteristics, Ease of integration and improved response efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

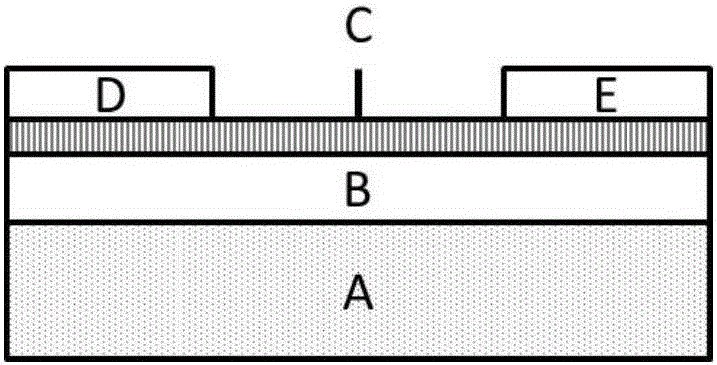

[0066] Prepare the organic field effect transistor sensor according to the following steps:

[0067] 1) Use a silicon wafer with a thickness of 1mm as the gate, and prepare SiO with a thickness of 300nm on the gate layer by thermal oxidation growth method 2 as an insulating layer;

[0068] 2) Prepare the organic sensing layer on the insulating layer obtained in step 1) by shearing and pulling the film. The solvent is toluene, the solution volume is 20 μL, the film pulling speed is 0.15-0.30 mm / s, and the temperature of the silicon wafer is 70 ° C. The experiment was carried out in an open system, and the compound of formula I with the following structure was used as the material of the organic sensing layer:

[0069]

[0070] Formula I1

[0071] Among them, heteroatom X=S, m=2; R 1 =R 2 =-C 6 h 13 ;

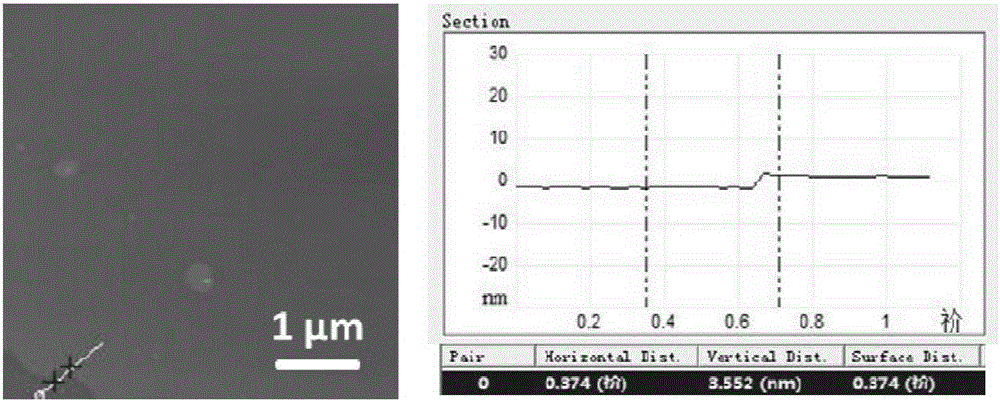

[0072] Such as image 3 As shown in the atomic force microscope photo, the obtained organic sensing layer is uniform and continuous, with a thickness of 3.55nm, whic...

Embodiment 2

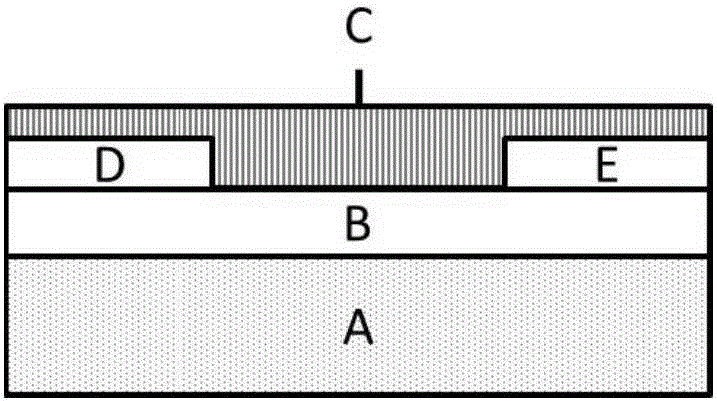

[0089] Prepare the organic field effect transistor sensor according to the following steps:

[0090] 1) Use a silicon wafer with a thickness of 1mm as the gate, and prepare SiO with a thickness of 300nm on the gate layer by thermal oxidation growth method 2 as an insulating layer;

[0091] 2) On the insulating layer obtained in step 1), use vacuum evaporation (vacuum degree is 10 -4 Pa, the evaporation rate is ) method to prepare gold electrodes, respectively as the source electrode and the drain electrode, the thickness is 20nm;

[0092] 3) Prepare an organic sensing layer on the insulating layer obtained in step 2) by spin coating. The solvent used in the spin coating step is tetralin, the spin coating speed is 6000rpm, and the time is 2 to 3min. It is carried out at room temperature. The compound belonging to the formula I of the structure shown in the following formula I2 is used as the material of the organic sensing layer to obtain the organic field effect transistor...

Embodiment 3

[0106] According to the steps of Example 1, only the material of the organic sensing layer is replaced by the compound shown in formula I3;

[0107] Atomic force microscope photo ( Figure 9 ) shows that the thickness of the organic sensing layer is 7.2 nm, which is ~2 molecular layers;

[0108]

[0109] Formula I3

[0110] Among them, heteroatom X=S, m=2; R 1 =R 2 =-OC 6 h 13 ;

[0111] The performance of the transistor sensor obtained in this embodiment is not substantially different from that of embodiment 1 in terms of ammonia detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com