Sea fish mixed feed for deepwater net cage culture and manufacturing method thereof

A technology of compound feed and deep-water cages, applied in animal feed, animal feed, application, etc., can solve the problems of unusable floating feed, unfavorable feeding of farmed fish, and difficulty in controlling the feeding amount, so as to reduce loss, reduce Phosphorus emission and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

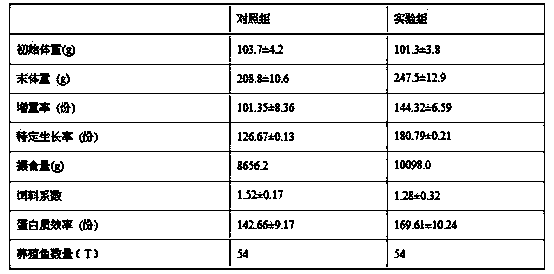

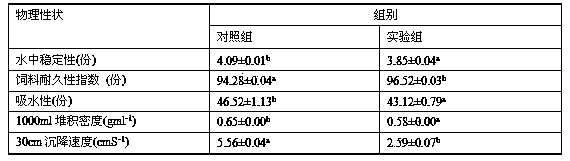

Embodiment 1

[0033] A seawater fish compound feed suitable for deep-water net cage culture is composed of the following raw materials, the weight parts of each component are: 10 parts of fish meal, 55 parts of enzymatic protein raw material, 10 parts of soybean meal, 10 parts of flour, and 4 parts of fish oil , 5 parts of squid offal powder, 2 parts of mineral premix, 1 part of vitamin premix, 0.5 part of choline chloride, 1 part of calcium dihydrogen phosphate, 0.6 part of coated lysine, 0.4 part of coated methionine, Adhesive 0.5 parts.

[0034] The vitamin premix adopts commercially available aquatic product-specific compound vitamins, and the mineral premix adopts commercially available aquatic product-specific compound minerals.

[0035] The raw material of enzymatic protein is fresh fish paste, soybean meal, peanut meal, cottonseed protein, soybean protein, blood cell powder, meat and bone meal, and corn gluten powder, which are made by enzymatic hydrolysis and drying.

[0036] The ...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is:

[0050] The seawater fish compound feed suitable for deep-water net cage culture of the present embodiment is composed of the following raw materials, which are respectively in parts by weight of each component: 15 parts of fish meal, 50 parts of enzymatic protein raw material, 12 parts of soybean meal, and 8 parts of flour , 5 parts of fish oil, 4 parts of cuttlefish viscera powder, 1.5 parts of mineral premix, 1.2 parts of vitamin premix, 0.6 part of choline chloride, 1.2 parts of calcium dihydrogen phosphate, 0.7 part of coated lysine, coated 0.2 parts of methionine, 0.7 parts of binder.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is:

[0053] The seawater fish compound feed suitable for deep-water net cage culture of the present embodiment is composed of the following raw materials, and the parts by weight of each component are: 60 parts of enzymatic protein raw materials, 9 parts of soybean meal, 14 parts of flour, and 5 parts of fish oil , 6 parts of squid offal powder, 2.3 parts of mineral premix, 0.8 part of vitamin premix, 0.4 part of choline chloride, 0.8 part of calcium dihydrogen phosphate, 0.8 part of enveloped lysine, 0.3 part of enveloped methionine, Adhesive 0.6 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com