Insulating paint with high punching performance for non-oriented electrical steel, and preparation method and application thereof

A technology of insulating coatings and high punching, which is applied in the direction of epoxy resin coatings, coatings, and devices for coating liquid on the surface, etc. Problems such as poor surface state of the layer can be achieved to improve the service life and product processing accuracy, improve the adhesion performance and insulation performance, and improve the ability of passivation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] Example 1: Number No.1

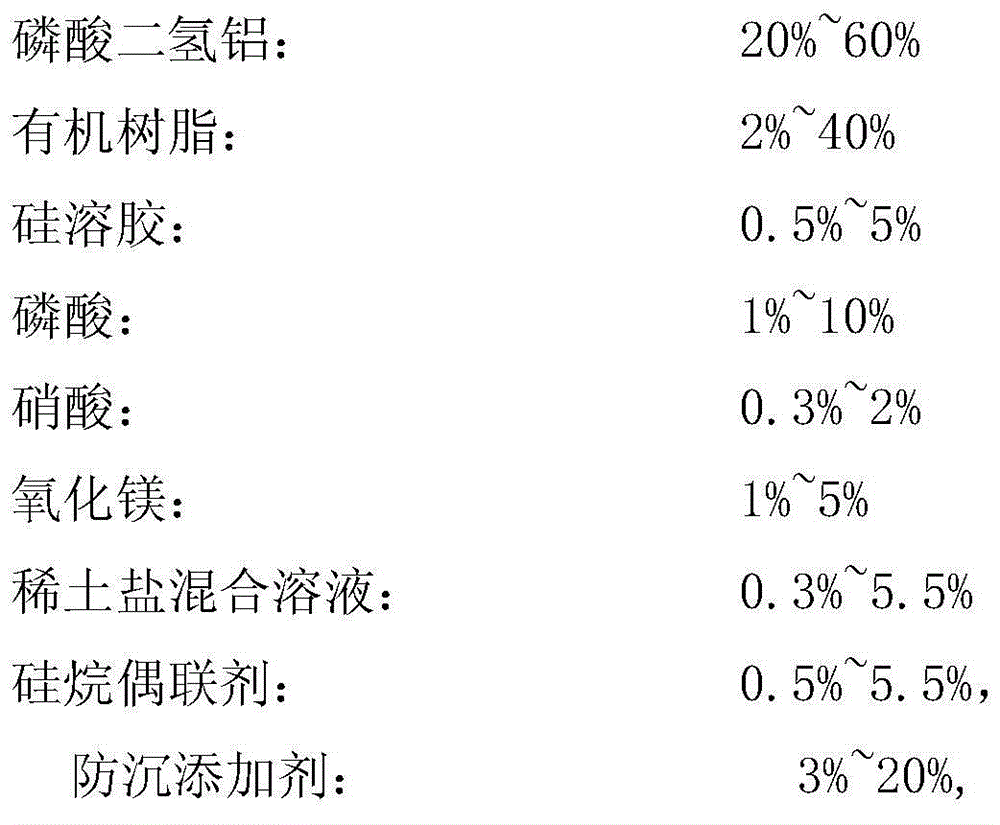

[0123] According to the following ratio, the non-oriented electrical steel environmental protection insulating coating with high punching performance of the present invention is prepared:

[0124]

[0125] The rest is solvent water.

[0126] In this embodiment, the organic resin is one of a highly dispersible waterborne acrylic resin, a waterborne epoxy resin or a composite thereof, and preferably a waterborne acrylic-waterborne epoxy resin composite.

[0127] In this embodiment, the rare earth salt mixed solution is a solution of rare earth salt, peroxide, buffer and nitric acid, and its mixing ratio is:

[0128]

[0129] The rest is solvent water.

[0130] In this embodiment, the rare earth salt in the rare earth salt mixed solution is selected from cerium nitrate and praseodymium chloride, and its mass ratio is 3:1. The peroxide in the rare earth salt mixed solution is hydrogen peroxide and sodium peroxide, and the mass ratio of hydrogen peroxide and s...

Embodiment 2

[0155] Example 2: Number No. 2

[0156] Except for the following differences, the others are the same as in Example 1:

[0157]

[0158]

[0159] The rest is solvent water.

[0160] In this embodiment, the rare earth salt mixed solution is a solution of rare earth salt, peroxide, buffer, and nitric acid, and its mixing ratio is:

[0161]

[0162] The rest is solvent water.

[0163] In this embodiment, the rare earth salt in the rare earth salt mixed solution is selected from neodymium nitrate and praseodymium chloride, and the mass ratio is 2:1. The peroxide in the rare earth salt mixed solution is hydrogen peroxide and potassium peroxide, and the mass ratio of hydrogen peroxide and potassium peroxide is 3:2. The buffering agent in the rare earth salt mixed solution is boric acid and acetic acid, and the mass ratio of boric acid and acetic acid is 5:2.

[0164] In this embodiment, the anti-settling additive is a solution of mineral soil, xanthan gum, and cellulose thickener, and the mi...

Embodiment 3

[0172] Example 3: Number No.3

[0173] Except for the following differences, the others are the same as in Example 1:

[0174]

[0175] The rest is solvent water.

[0176] In this embodiment, the rare earth salt mixed solution is a mixed solution of cerium nitrate, cerous chloride, praseodymium chloride, sodium peroxide, boric acid, and nitric acid, and the mixing ratio is:

[0177]

[0178] The rest is solvent water.

[0179] In this embodiment, the anti-settling additive is a solution of natural mica powder, gum thickener, and cellulose thickener. The mixing ratio is:

[0180] Natural mica powder: 3%,

[0181] Gum thickener: 4%,

[0182] Cellulose thickener: 5%,

[0183] The rest is solvent water.

[0184] In this embodiment, the gum thickener in the anti-settling additive is guar gum and gum arabic, and the mass ratio of guar gum and gum arabic is 2:1. The cellulose thickener in the anti-settling additive is 30,000-type cellulose and 100,000-type cellulose, and the mass ratio of 30,000-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com